EP-9YG-2.24D-Round baler-S9000 Classic

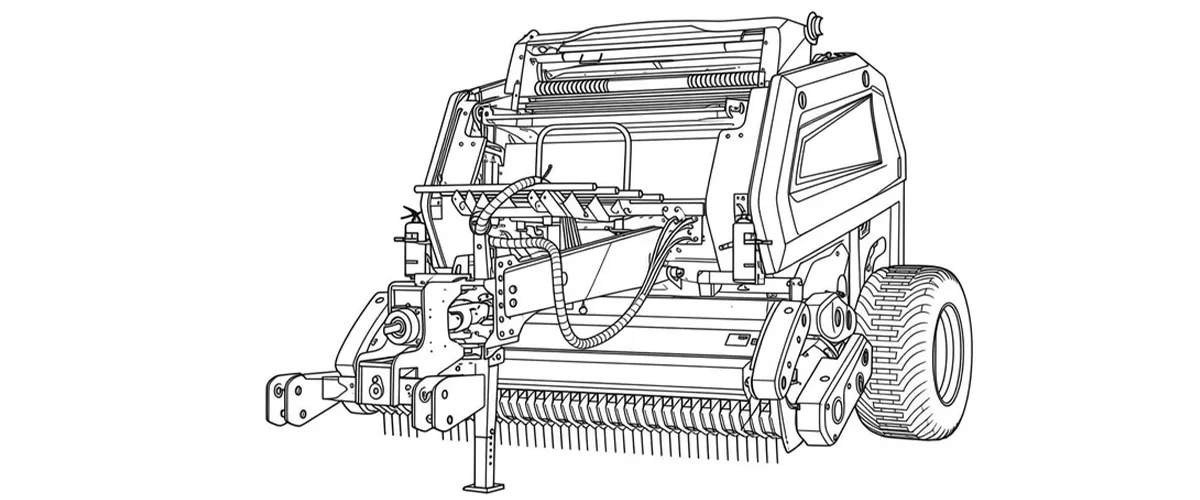

The 9YG-2.24D (S9000 Classic) Round Baler by EVER-POWER is a high-performance agricultural machine designed for challenging environments. Tailored to meet the needs of farmers in regions with uneven, small terraced fields, such as those found in South Korea’s rice-growing belts, the S9000 Classic combines robust engineering with advanced features. Weighing 4312 kg and equipped with a 30° tilt and 100° steering angle, this baler ensures optimal maneuverability on uneven terrain while minimizing mechanical failures.

Its heavy-duty construction features a powerful 18-roller compression system, capable of producing high-density bales—up to 500kg each—making it ideal for silage production. The machine’s sensor-controlled forage density system guarantees that each bale reaches the perfect compression level for optimal fermentation and storage. Additionally, the S9000 Classic excels in environments where high-moisture crops, like rice straw, are prevalent, thanks to its reinforced steel rollers that resist wear from abrasive materials.

With an efficient PTO system and a high-capacity pickup width of 2240mm, this baler ensures quick field clearance, improving productivity and helping farmers meet tight deadlines for government subsidies. The S9000 Classic is perfect for a variety of global applications, including hay baling, corn stalk handling, and sugarcane residue management, offering both reliability and performance for high-density baling needs. Whether for dairy farms or bioenergy projects, this machine provides efficient and cost-effective solutions for modern agricultural operations.

1. Technical Specifications: 9YG-2.24D (S9000 Classic)

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Classic) |

| 2 | Hitch Type | / | Trailed |

| 3 | Pickup Width | mm | 2240 |

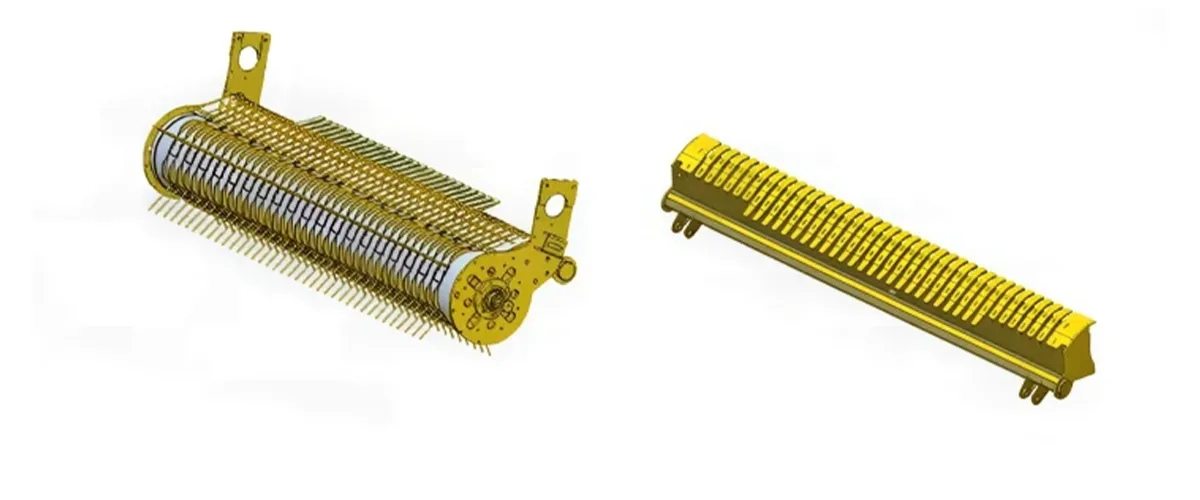

| 4 | Pickup Structure Type | / | Ball Type |

| 5 | Feeding Mechanism Structure | / | Feeding Rotor + Roller Type |

| 6 | Compression Chamber Structure | / | Roller Chamber |

| 7 | Compression Chamber Width | mm | 1400 |

| 8 | Compression Chamber Diameter | mm | 1200 |

| 9 | Number of Roller Working Components | pcs | 18 (Rollers) |

| 10 | Roller Diameter | mm | 222 |

| 11 | Baling Method | / | Net Wrapping |

| 12 | Required Power | kW | 55-100 |

| 13 | Structural Weight | kg | 4312 |

| 14 | PTO Output Shaft Speed | r/min | 720 |

| 15 | Dimensions (L × W × H) | mm | 4470 × 3010 × 2370 (working condition) |

| 16 | Forage Density Control | / | Sensor-Controlled |

| 17 | Bale Size (Length × Width × Height) | mm | 1300 × 1400 |

| 18 | Bale Density | kg/m³ | 100–200 |

| 19 | Productivity | bale/h | 40–100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Operating Speed | km/h | 5–35 |

| 22 | Net Wrap Specification | m | 2000×1.4 / roll |

2. Introducing the S9000 Classic

- Eco-Friendly Straw Management (Fine Dust Reduction): South Korea strictly enforces the Wastes Control Act and measures to reduce fine dust pollution, banning the open burning of rice straw. The S9000 Classic's high-capacity pickup (2240mm) allows for rapid clearance of fields, converting potential waste into valuable biomass fuel or feed, keeping farmers compliant with environmental laws.

- Subsidy Optimization (Direct Payment for Fodder): The quality of silage is paramount for receiving the maximum tier of the "Domestic Forage Production Subsidy." Quality is largely determined by density and fermentation. The S9000 Classic's 18-roller system and hydraulic locking mechanism ensure bales achieve the necessary anaerobic conditions to prevent spoilage, securing higher payouts for farmers.

- Road Traffic Act Compliance: While the machine is 3010mm wide in working mode, its comprehensive lighting and reflective safety system comply with Korean agricultural machinery road transport regulations. However, operators are advised to use escort vehicles when transporting on narrow rural roads (Nong-ro) to ensure full legal compliance.

4. Engineering Excellence: Working Principle & Compatibility

Working Principle: The S9000 Classic operates on a "Semi-Forced Axial Flow" principle. As the tractor tows the unit, the 2240mm cam-less spring tooth pickup lifts the windrow. Unlike traditional augers that can wrap and jam with long, wet rice straw, the S9000 utilizes a Dial Tine Roller and Drum combination to forcefully feed the crop into the main chamber. Inside, 18 high-strength steel rollers (Φ222mm) rotate to tumble the crop. As the bale grows, hydraulic sensors monitor density. Once the preset pressure is reached, the net binding system triggers automatically, wrapping the bale in seconds before the hydraulic buffer cylinders gently eject it.

5. Application Scenarios

5.1. South Korea – Rice Paddy Harvesting

In regions like Jeollanam-do and Gyeongsangbuk-do, where rice paddies are small, terraced, and often on uneven ground, the S9000 Classic provides a reliable solution. Its 30° tilt and 100° steering angle allows farmers to navigate these challenging terrains without causing mechanical failures, ensuring that farmers can meet stringent Direct Payment for Fodder deadlines.

5.2. Japan – High-Density Silage Production

In Japan’s rice-growing regions, where winter fodder production is critical, the S9000 Classic produces high-density bales (up to 500kg per bale). This is ideal for silage used in dairy and cattle farming, meeting the growing demand for quality feed while ensuring compliance with local environmental regulations on straw burning.

5.3. United States – Corn Stalk Baling in the Midwest

For large-scale farms in the Midwest dealing with post-harvest corn stalks, the S9000 Classic provides the heavy-duty compression needed to process tough, fibrous material. The machine’s robust 18-roller compression system can handle the abrasive nature of corn stalks, ensuring long-term durability and efficient baling.

5.4. Brazil – Sugarcane Straw Management

In Brazil, where sugarcane residue management is crucial for biomass energy production, the S9000 Classic helps clear fields quickly. Its high-speed operation (up to 100 bales per hour) and large pickup width (2240mm) make it an excellent choice for farmers needing to handle large quantities of sugarcane straw for bioenergy applications.

5.5. Australia – Hay Baling in Dryland Farms

On Australian dryland farms, where high-density bales are needed for efficient storage and transport, the S9000 Classic delivers. Its ability to form bales with densities ranging from 100-200 kg/m³ ensures that hay and silage can be stored for longer periods and transported efficiently across vast distances.

5.6. Russia – Winter Wheat Straw Baling

In Krasnodar, Russia, where winter wheat production is a key agricultural activity, the S9000 Classic effectively handles dense straw. Its reinforced steel rollers can compress the tough, silica-rich straw without rapid wear, making it perfect for baling and managing wheat straw in preparation for the winter.

5.7. France – Silage Production for Cattle Feed

In France, especially in Brittany, known for its dairy production, the S9000 Classic is used to create silage for cattle feed. The 20A double-chain compression system ensures that bales are tightly packed to exclude oxygen, which is crucial for producing high-quality, well-fermented silage.

5.8. South Africa – Forage Baling on Cattle Farms

On large cattle farms in South Africa, the S9000 Classic is used to bale forage and silage. Its efficient net wrapping system and fast productivity (up to 100 bales per hour) allow farmers to quickly produce large quantities of silage, which is essential for maintaining cattle nutrition during the dry seasons.

5.9. New Zealand – Pasture Management for Dairy Farms

In New Zealand, known for its large dairy industry, the S9000 Classic helps manage pasture grass and convert it into silage. The machine's ability to handle wet grass without clogging, thanks to its axial flow feeding system, makes it a preferred choice for dairy farmers looking to produce high-quality silage.

5.10. China – Straw Collection for Bioenergy Plants

In regions of China, where the government is encouraging bioenergy plants to use agricultural waste, the S9000 Classic is instrumental in collecting rice, wheat, and corn straw. With its efficient field clearance and high bale density, it transforms agricultural residue into usable biomass for energy production, helping meet China's renewable energy targets.

6. Tractor & Component Compatibility Matrix

| Tractor Brand / Series | Min Power Requirement | PTO Compatibility | Hydraulic Requirement | Recommendation Status |

|---|---|---|---|---|

| LS Mtron (XP Series) | 85 HP | 540/720/1000 RPM | 2 Sets of Remote Valves | Highly Recommended |

| TYM (T1003 / T1104) | 90 HP | Standard Spline | High Flow Pump Preferred | Compatible |

| Daedong (Kioti HX Series) | 90 HP | Standard | Standard | Compatible |

| Kubota (M Series) | 95 HP | Check Shaft Length | Standard | Requires Check |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

7. Global Forage Harvesting Trends: The Shift to High-Density

The global agricultural machinery market is witnessing a decisive shift from "Volume" to "Density." In markets like South Korea, Japan, and parts of Europe, land availability is shrinking, and logistics costs are rising. Transporting loose or low-density bales is no longer economically viable. The trend is moving towards Fixed Chamber Roller Balers like the S9000 Classic because they offer superior durability compared to belt balers when handling abrasive crops like rice straw, which contains high levels of silica.

Furthermore, the integration of "Smart Farming" is accelerating. While the S9000 Classic is a mechanical workhouse, EVER-POWER is actively developing sensor upgrades compatible with ISOBUS standards, allowing future iterations to communicate directly with the tractor's ECU for automated speed adjustment based on swath volume—a feature that will define the next decade of harvesting.

8. About us | EVER-POWER Manufacturing: Your Partner in Customization

Located in a National Economic and Technological Development Zone, EVER-POWER Machinery Co., Ltd. operates a state-of-the-art 32,000 square meter facility. With a registered capital of 10 million yuan and a workforce of 180 skilled technicians, we are not just assembling parts; we are manufacturing solutions. Our facility boasts CNC laser cutting, robotic welding lines, and a dedicated electrostatic powder coating line ensuring our balers resist corrosion in humid Asian climates.

OEM & Customization ServicesWe understand that dealers need to differentiate themselves. For our Korean partners, we offer extensive customization services:

- Brand Livery: Custom paint codes (e.g., matching LS Blue or John Deere Green).

- Hitch Adaptation: Modified drawbars to suit local 3-point hitch geometries.

- Reinforced Undercarriage: Optional skid plates for rocky terrain in mountainous provinces.

9. Customer Success Case

"We’ve been using the S9000 Classic for corn stalks, and it’s a powerhouse. The heavy-duty 20A chain system really helps in making denser bales. The stability and build quality are unmatched. It's built to last and definitely worth the investment!"

--- Tom from California, USA

"We were worried about compliance with the Clean Air Conservation Act, but the S9000 Classic handles rice straw with ease. No more burning! Plus, it clears our fields quickly and efficiently, allowing us to meet the deadlines set by the government without any issues."

---Min-Ho from Chungcheongnam-do, South Korea:

"On our cattle farm, the quality of silage is key. The S9000 Classic has been a game changer. Its hydraulic system and sensor-controlled density ensure that every bale is perfect for fermentation. We’re baling faster and improving our feed quality, which has boosted our cattle’s health."

---Johan from Western Cape, South Africa

"We’ve been using the S9000 Classic for winter wheat, and it’s made a huge difference. The baler handles the tough wheat straw effortlessly, and the improved bale quality is evident. Plus, the compatibility with our local tractors means we didn’t face any technical difficulties during setup."

----Mikhail from Krasnodar, Russia

"In Japan, where silage quality matters, the S9000 Classic has been fantastic. The bale density is perfect for our dairy cows, and the machine’s ability to work in challenging, uneven fields makes it ideal for our mountainous terrain. It's truly a high-performing and durable baler."

---Yuki from Hokkaido, Japan

10. Replaceable parts

10.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:

Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

10.2 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

10.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

10.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

11. Other products in the same series (2.24D)

11. Frequently Asked Questions (FAQ)

Q1. How does the S9000 Classic's 4312kg weight affect soil compaction in wet Korean paddies?

Q2. Can the 9YG-2.24D S9000 handle the high silica content of Korean rice straw without rapid wear?

Q3. What is the specific advantage of the "H-type hydraulic joint" for daily operations?

Q4. Is the PTO shaft compatible with standard Korean tractor brands like LS and TYM?

Q5. How does the "buffer cylinder" feature reduce maintenance costs for the baler?

Q6. What is the minimum horsepower required to safely operate this baler on hilly terrain?

Q7. Does EVER-POWER provide spare parts like the 20A chains and pickup tines locally in Korea?

Q8. Can this baler process winter crops like Italian Ryegrass and Whole Crop Barley?

Q9. What safety features are included for the operator during blockage clearing?

Q10. Is it possible to customize the net wrapping system for different net widths available in Korea?

Editor: PXY