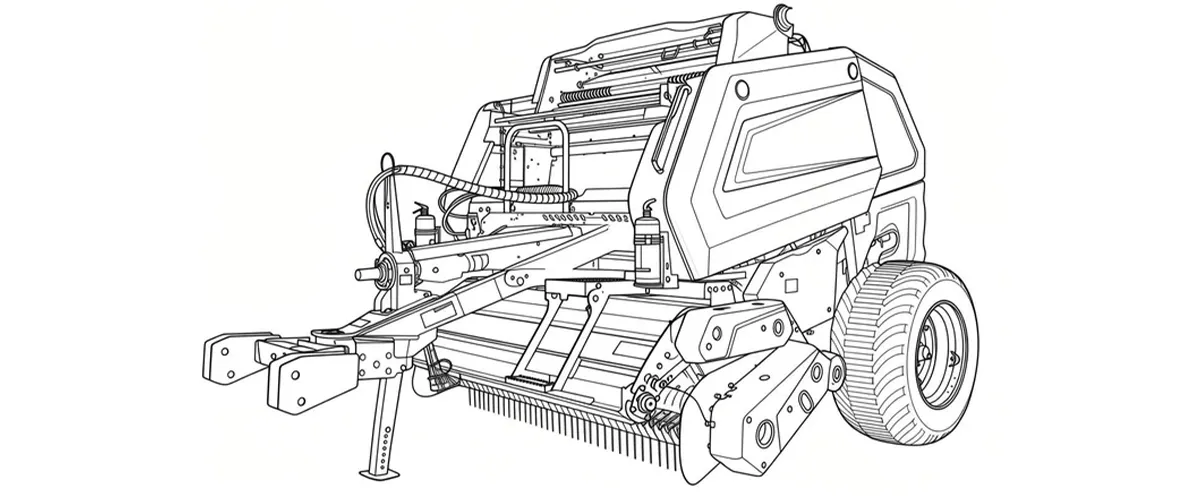

EP-9YG-2.24D-بیلر گرد-S9000

EVER-POWER 9YG-2.24D (مدل S9000) اوج فناوری عدلبندی کششی را نشان میدهد که بهطور خاص برای غلبه بر چالشهای توپوگرافی چشمانداز کشاورزی کره جنوبی مهندسی شده است. برخلاف مدلهای استاندارد، S9000 دارای یک دستگاه کشش قابل تنظیم انقلابی با قابلیت شیب جانبی 30 درجه و یک سیستم زنجیر دو طرفه تقویتشده 20A است. با جرم ساختاری 4262 کیلوگرم و یک محفظه فشردهسازی 18 غلتکی، چگالی عدل برتر (تا 500 کیلوگرم در هر عدل) را برای کاه و علوفه برنج ارائه میدهد و انطباق کامل با مقررات زیستمحیطی و یارانهای کره را تضمین میکند.

۱. مشخصات فنی: 9YG-2.24D (S9000)

| خیر. | مورد | واحد | مشخصات |

|---|---|---|---|

| 1 | نام مدل | / | دستگاه پرس بیلر گرد 9YG-2.24D (S9000) |

| 2 | نوع اتصال | / | دنبالهدار |

| 3 | عرض برداشت | میلیمتر | 2240 |

| 4 | نوع ساختار وانت | / | نوع توپ |

| 5 | ساختار مکانیسم تغذیه | / | نوع تغذیه روتور + غلتک |

| 6 | ساختار محفظه فشرده سازی | / | محفظه غلتکی |

| 7 | عرض محفظه فشرده سازی | میلیمتر | 1400 |

| 8 | قطر محفظه فشرده سازی | میلیمتر | 1200 |

| 9 | تعداد اجزای کاری غلتک | رایانههای شخصی | ۱۸ (غلتک) |

| 10 | قطر غلتک | میلیمتر | 222 |

| 11 | روش عدل بندی | / | بسته بندی خالص |

| 12 | توان مورد نیاز | کیلووات | 55-100 |

| 13 | وزن سازه | کیلوگرم | 4262 |

| 14 | سرعت شفت خروجی PTO | دور در دقیقه | 720 |

| 15 | ابعاد (طول × عرض × ارتفاع) | میلیمتر | ۴۲۴۰ × ۳۰۱۰ × ۲۴۵۰ (در شرایط کاری) |

| 16 | کنترل تراکم علوفه | / | کنترلشده با حسگر |

| 17 | اندازه عدل (طول × عرض × ارتفاع) | میلیمتر | ۱۳۰۰ × ۱۴۰۰ |

| 18 | تراکم عدل | کیلوگرم بر متر مکعب | ۱۰۰–۲۰۰ |

| 19 | بهرهوری | عدل/ساعت | ۴۰–۱۰۰ |

| 20 | فاصله بین دو محور | میلیمتر | 2600 |

| 21 | سرعت عملیاتی | کیلومتر در ساعت | ۵–۳۵ |

| 22 | مشخصات بسته بندی خالص | متر | 2000×1.4 / رول |

۲. پنج حقیقت کلیدی

۱. سازگاری بیشتر با زمین برای مزارع برنج کرهای

مدل S9000 دارای زاویه شیب جانبی 30 درجه و زاویه فرمان افقی 100 درجه در سیستم کشش خود است که به آن اجازه میدهد به راحتی در زمینهای ناهموار و تپهای شالیزارهای برنج کره جنوبی بدون ایجاد فشار گشتاور یا خرابی مکانیکی حرکت کند.

۲. تراکم بالای عدل برای سیلاژ مرغوب

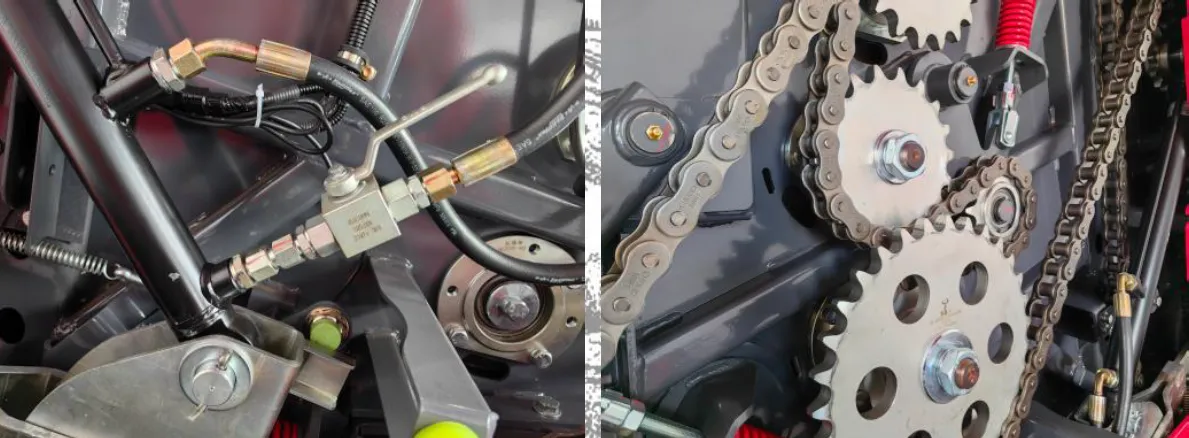

دستگاه S9000 مجهز به سیستم فشردهسازی دو زنجیرهای 20A است که فشار فشردهسازی را به میزان قابل توجهی افزایش میدهد و به دستگاه بستهبندی اجازه میدهد تا بستههای متراکمتری (از 250 کیلوگرم تا 500 کیلوگرم در هر بسته) ایجاد کند که برای تولید سیلو با کیفیت بالا ایدهآل است و در نتیجه تقاضای رو به رشد برای بستههای با چگالی بالا در صنعت کشاورزی را برآورده میکند.

۳. رعایت مقررات کشاورزی کره جنوبی

دستگاه S9000 به گونهای طراحی شده است که با بستهبندی کارآمد کاه برنج بدون نیاز به سوزاندن، به کشاورزان در رعایت قانون حفاظت از هوای پاک کمک کند. این دستگاه با بهرهوری تا ۱۰۰ بسته در ساعت کار میکند و آن را به یک راهحل سریع و مؤثر برای پاکسازی مزارع مطابق با استانداردهای زیستمحیطی تبدیل میکند.

۴. بهبود حفاظت از خاک با فاصلهی بین دو محور عریض

با وجود وزن ۴۲۶۲ کیلوگرمی، S9000 دارای فاصله بین دو محور ۲۶۰۰ میلیمتری و لاستیکهای شناور بزرگی است که وزن دستگاه را به طور مساوی توزیع میکنند، فشردگی خاک را به حداقل میرسانند و حفظ ساختار خاک شالیزار را برای کاشتهای آینده تضمین میکنند.

۵. ادغام یکپارچه با برندهای محلی تراکتور

S9000 کاملاً با انواع برندهای تراکتور محبوب کره جنوبی مانند LS Mtron، TYM و Kubota سازگار است و نیازهای توان انعطافپذیری از 55 تا 100 کیلووات را ارائه میدهد و آن را با اندازههای مختلف مزرعه و ناوگان تراکتور سازگار میکند.

۳. بازتعریف بهرهوری برداشت: مزیت S9000 در کشاورزی کره

در دنیای پرزحمت کشاورزی مدرن، به ویژه در بافت جغرافیایی منحصر به فرد کره جنوبی، رویکرد «یکسان برای همه» به ماشینآلات اغلب با شکست مواجه میشود. کشاورزان در مناطقی مانند جئولابوک-دو و چونگچئونگنام-دو با یک چالش دوگانه روبرو هستند: شالیزارهای برنج کوچک و قطعه قطعه که اغلب در زمینهای ناهموار و تپهای قرار دارند، و الزام سختگیرانه برای بستههای با تراکم بالا برای به حداکثر رساندن یارانههای حفظ علوفه. دستگاه پرس بیلر گرد 9YG-2.24D (S9000) صرفاً یک ارتقا نیست؛ بلکه پاسخی تخصصی به این نیازهای دقیق است. S9000 ضمن حفظ سیستم تغذیه جریان محوری اثباتشده سری کلاسیک، پیشرفتهای ساختاری مهمی را معرفی میکند که آن را به عنوان انتخاب برتر برای پیمانکاران حرفهای و تعاونیهای بزرگ متمایز میکند.

ویژگی تعیینکنندهی مدل S9000 سازگاری پیشرفته آن با زمین است. دستگاههای بستهبندی کششی استاندارد اغلب از سیستمهای اتصال سفت و سختی رنج میبرند که فقط امکان تنظیم افقی را فراهم میکنند. این محدودیت هنگام پیمایش در پشتهها و شیبهای معمول مزارع برنج کرهای، به یک مشکل جدی تبدیل میشود و اغلب منجر به تنش گشتاور و خرابی مکانیکی قاب کششی میشود. S9000 این مشکل را با یک دستگاه کششی جدید با حداکثر ظرفیت گشتاور 1000 نانومتر حل میکند. نکته مهم این است که این دستگاه ارائه میدهد قابلیت تنظیم شیب جانبی تا 30 درجه و زاویه فرمان افقی تا 100 درجهاین انعطافپذیری تضمین میکند که دستگاه بستهبندی به صورت روان تراکتور را روی زمین مواج دنبال میکند و از سیستم انتقال قدرت محافظت میکند.

علاوه بر این، S9000 تراکم و دوام بسته را در اولویت قرار میدهد. با توجه به تغییر بازار به سمت سیلوی با کیفیت بالا، محفظه عقب S9000 با یک سیستم زنجیر سنگین دو طرفه 20A ارتقا یافته است. این مکانیزم انتقال قوی، فشار فشردهسازی اعمال شده به بسته را به میزان قابل توجهی افزایش میدهد و امکان دستیابی به تراکمهایی را فراهم میکند که میتوانند بین 250 کیلوگرم تا 500 کیلوگرم در هر بسته (بسته به رطوبت محصول) برسند.

۴. تحلیل استراتژیک بازار

ورود به بازار ماشینآلات کشاورزی کره جنوبی چیزی بیش از فروش سختافزار است؛ این امر مستلزم درک عمیق از محیط نظارتی است که به عنوان ... شناخته میشود. نونگ-جئونگ9YG-2.24D S9000 به گونهای مهندسی شده است که مستقیماً از کشاورزان در رعایت طرحهای حیاتی دولت، به ویژه در مورد مدیریت کاه برنج و حفاظت از محیط زیست، حمایت کند.

۴.۱ رعایت «پرداخت مستقیم برای محصولات علوفهای»

وزارت کشاورزی، غذا و امور روستایی کره (MAFRA) به طور فعال تولید علوفه خشک داخلی را ترویج میدهد تا وابستگی به خوراک دام وارداتی را کاهش دهد. "برنامه پرداخت مستقیم" به کشاورزانی که سیلوی با کیفیت بالا تولید میکنند، یارانه میدهد. با این حال، کیفیت اغلب با تراکم بسته و موفقیت تخمیر درجهبندی میشود. S9000 سیستم فشردهسازی دو زنجیرهای 20A تضمین میکند که هر عدل، الزامات چگالی بالای لازم برای حذف مؤثر اکسیژن را برآورده میکند و تخمیر بهینه را ارتقا میدهد. این امر مستقیماً به کشاورزان کمک میکند تا با تولید کاه برنج با کیفیت برتر (نونگ-لیم) واجد شرایط دریافت یارانههای سطح بالاتر شوند.

۴.۲. الزامات زیستمحیطی: قانون حفاظت از هوای پاک

محدودیتهای شدیدی برای سوزاندن محصولات جانبی کشاورزی در فضای باز در سراسر کره اعمال شده است تا با آلودگی ناشی از ریزگردها مقابله شود. کشاورزان اکنون باید بقایای کاه خود را بستهبندی کنند. S9000 امکان پاکسازی سریع مزرعه را با بهرهوری تا ۱۰۰ بسته در ساعت فراهم میکند. تغذیه نیمه اجباری جریان محوری این مکانیزم به ویژه در مدیریت کاه برنج سفت و اغلب مرطوب موجود در پاییز کره مهارت دارد و از انسدادهایی که ماشینهای کوچکتر را آزار میدهد، جلوگیری میکند. این قابلیت اطمینان تضمین میکند که کشاورزان میتوانند مزارع را به سرعت پاکسازی کنند و بدون تأخیر در کاشت محصولات پوششی زمستانی مانند چاودار یا جو، از قوانین ضد آتشسوزی پیروی کنند.

۴.۳ حفاظت از زمین و خاک

شالیزارهای کرهای داراییهای ارزشمندی هستند و فشردگی خاک از نگرانیهای اصلی آنهاست. با وجود وزن سنگین ۴۲۶۲ کیلوگرمی، S9000 با چرخهای عریض ۲۶۰۰ میلیمتری طراحی شده و از لاستیکهای شناور بزرگ استفاده میکند. این طراحی وزن دستگاه را به طور مساوی توزیع میکند، ردپای آن را به حداقل میرساند و فشردگی عمیق خاک (تشکیل تشتک) را کاهش میدهد. علاوه بر این، منحصر به فرد اتصال شیب 30 درجه از فرو رفتن بستهبندیکننده در خاک هنگام عبور از شیبهای تند ورودی و خروجی شالیزارهای پلکانی جلوگیری میکند و یکپارچگی فیزیکی خاکریزهای شالیزاری را حفظ میکند (Non-du-reong).

۵. اصول کار و سازگاری اجزا

فناوری اصلی: S9000 بر اساس یک اصل جریان پیوسته پیچیده کار میکند. همزمان با یدککشی، وانت با عرض ۲۲۴۰ میلیمتر - با استفاده از طراحی دندانه فنری بدون بادامک - محصول را بلند میکند. نوآوری تعیینکننده این است که سیستم تغذیه جریان محوریبرخلاف متههای سنتی که محصول را به مرکز فشار میدهند، ترکیب روتور و غلتک دندانهای ما به طور فعال مواد را به داخل محفظه فشار میدهد. این امر برای ... بسیار مهم است. محصولات مرطوب (سیلو)، زیرا "مناطق مرده" را که معمولاً کاه مرطوب در آنها جمع شده و مسدود میشود، از بین میبرد. در داخل محفظه، ۱۸ غلتک فولادی با استحکام بالا (Φ۲۲۲ میلیمتر) میچرخند تا عدل را تشکیل دهند. شبکه حسگر پیشرفته، افزایش فشار را رصد میکند و تنها زمانی که به تراکم هدف برسد، پیچیدن تور آغاز میشود.

۶. سناریوهای کاربردی

6.1. کره جنوبی: مدیریت کاه برنج

کاربرددستگاه S9000 در کار با کاه برنج مرطوب که یک مشکل اساسی در فصل بارندگیهای موسمی کره جنوبی است، عالی عمل میکند. سیستم تغذیه جریان محوری از گرفتگی جلوگیری میکند و کشاورزان را قادر میسازد تا کاه برنج را بدون نیاز به سوزاندن، به طور موثر جمعآوری کنند. این به آنها کمک میکند تا با ... مطابقت داشته باشند. قانون حفاظت از هوای پاک با تولید کاه برای خوراک دام یا زیستتوده، به جای مشارکت در آلودگی هوا.

6.2. ایالات متحده: برداشت ساقه ذرت

کاربرددر غرب میانه، جایی که ساقههای ذرت پس از برداشت فراوان هستند، S9000 برای مدیریت بقایای متراکم محصولات ایدهآل است. تراکم عدل بالا و عملیات با سرعت بالاکشاورزان میتوانند مزارع بزرگ را به سرعت پاکسازی کنند و بستههای متراکمی تولید کنند که حمل و نقل و نگهداری آنها آسانتر است و هم کیفیت خوراک و هم استفاده از زیست توده را بهبود میبخشد.

6.3. روسیه: جمعآوری بقایای گندم زمستانی

کاربردکشاورزان روسی که با بقایای متراکم گندم زمستانه مواجه هستند، از S9000 بهره میبرند دوام و فشار تراکم بالاسنگین سیستم دو زنجیرهای ۲۰ آمپری امکان ایجاد عدلهای متراکمتر را فراهم میکند و تضمین میکند که کاه حتی در شرایط سخت و دشوار نیز به طور کارآمد جابجا میشود.

6.4. برزیل: برداشت بقایای نیشکر

کاربرددر برزیل، جایی که مزارع نیشکر بقایای قابل توجهی از خود به جا میگذارند، S9000 پیشنهاد میدهد عدل بندی با چگالی بالا برای مدیریت کارآمد مواد فیبری. مکانیزم فشردهسازی و تشکیل عدل قدرتمند آن، نیاز به سوزاندن را کاهش میدهد و با شیوههای کشاورزی پایدار برزیل همسو است.

6.5. استرالیا: عدلبندی کاه گندم و جو

کاربرددر مناطق گندم خیز استرالیا، S9000 مقادیر زیادی کاه گندم و جو را جابجا میکند و ... عملیات با سرعت بالا (تا سرعت ۳۵ کیلومتر بر ساعت) و تراکم عدل ثابتاین امر تضمین میکند که با به حداقل رساندن فشردگی، ضمن حفظ سلامت خاک، پسماندها به طور مؤثر مدیریت میشوند.

6.6. چین: جمعآوری زیستتوده برای انرژی زیستی

کاربردبه عنوان بخشی از گذار انرژی چین به سوختهای زیستی، S9000 سیستم کنترل تراکم حسگر تشکیل عدل را برای استفاده به عنوان سوخت زیستتوده بهینه میکند. توانایی این دستگاه در ایجاد عدلهای بسیار فشرده، حمل و نقل و ذخیرهسازی را کارآمدتر میکند و از تقاضای رو به رشد زیستتوده به عنوان یک منبع انرژی تجدیدپذیر پشتیبانی میکند.

6.7. هند: مدیریت کاه برنج در پنجاب

کاربرددر ایالت پنجاب، جایی که سوزاندن کاه برنج یک مشکل عمده زیستمحیطی بوده است، S9000 با تبدیل کاه برنج به خوراک دام یا بستر با کیفیت بالا، به مدیریت آن کمک میکند. سیستم تغذیه جریان محوری آن را برای جابجایی کاه مرطوب و سفت باقی مانده مناسب میکند، آلودگی را کاهش میدهد و به کشاورزان در رعایت مقررات زیستمحیطی کمک میکند.

6.8. آرژانتین: حفظ علوفه برای دامها

کاربرددر مزارع آرژانتین که کیفیت علوفه بسیار مهم است، از S9000 برای تولید ... استفاده میشود. سیلاژ با چگالی بالا عدلهای خوراک دام. دستگاه تراکم عدل ثابت و سیستم بسته بندی پیشرفته توری اطمینان حاصل کنید که علوفه در طول ذخیرهسازی و حمل و نقل به خوبی حفظ میشود، از فساد جلوگیری میکند و کیفیت خوراک دام را بهبود میبخشد.

6.9. آفریقای جنوبی: بستهبندی علوفه سیلو شده برای مزارع گاو

کاربرد: در آفریقای جنوبی، توانایی S9000 برای مدیریت علوفه با رطوبت بالا آن را به انتخابی ایدهآل برای تولید سیلاژ تبدیل میکند. این دستگاه تراکم عدل بالا و سیستم تغذیه پیشرفته تولید عدلهای فشرده و یکنواخت که به خوبی تخمیر میشوند را تضمین میکند و به کیفیت بهتر سیلاژ برای خوراک دام کمک میکند.

6.10. اوکراین: عدلبندی بقایای ذرت و آفتابگردان

کاربردکشاورزان اوکراینی از S9000 برای مدیریت بقایای سخت ذرت و آفتابگردان استفاده میکنند. سیستم عدل بندی با چگالی بالا عدلهای منسجم و فشردهای ایجاد میکند که حمل و نقل آنها آسان است، نیاز به سوزاندن بقایای مزرعه را کاهش میدهد و به شیوههای کشاورزی پایدارتر کمک میکند.

۷. مقایسه سازگاری و ارتقا

| ویژگی | بیلر گرد استاندارد | مدل اِوِر-پاور S9000 | مزیت برای کاربر کرهای |

|---|---|---|---|

| قلاب کششی | فقط تنظیم ثابت / افقی | شیب 30 درجه + چرخش 100 درجه قابل تنظیم | از شکستن قلاب در زمینهای تپهای/تراسدار جلوگیری میکند؛ چرخش ایمنتر. |

| زنجیرهای محرک | زنجیره استاندارد تک | دو طرفه 20A سنگین | گشتاور بالاتری را برای عدلهای متراکمتر تحمل میکند؛ عمر مفید طولانیتر. |

| وزن | تقریباً ۳۰۰۰ تا ۳۵۰۰ کیلوگرم | ۴۲۶۲ کیلوگرم (جرم سازهای) | پایداری بیشتر و فشار رو به پایین برای تشکیل عدل. |

| تراکتورهای سازگار | عمومی ۸۰ اسب بخار | LS Mtron، TYM، Kubota (55-100kW) | ادغام یکپارچه PTO و هیدرولیک با ناوگان محلی. |

۸. روندهای جهانی در فناوری برداشت علوفه

مسیر بازار جهانی بیلر با قاطعیت به سمت ... در حال حرکت است. «تراکم هوشمند» و "چابکی در زمین". در بازارهای بالغ مانند اروپا و بازارهای نوظهور با فناوری پیشرفته مانند کره جنوبی، روند از بستهبندیهای مکانیکی ساده به سمت ماشینهایی که چگالی بالاتری برای لجستیک زیستتوده ارائه میدهند، در حال تغییر است. ظهور نیروگاههای انرژی زیستی در آسیا، تقاضای جدیدی برای بستههای کاه به عنوان سوخت ایجاد کرده است، جایی که راندمان حمل و نقل (چگالی بالا) بسیار مهم است.

علاوه بر این، کمبود نیروی کار در مناطق روستایی ("روستاهای خالی") به این معنی است که یک اپراتور باید به آنچه که قبلاً برای یک تیم لازم بود، دست یابد. S9000 با ارائه عملیات پرسرعت (تا 35 کیلومتر در ساعت) و نگهداری کم (بدون مسیر بادامک) با این روند همسو است و به یک اپراتور واحد اجازه میدهد تا زمینهای وسیع را به طور کارآمد مدیریت کند. آینده عدلبندی نیز به هم پیوسته است. در حالی که S9000 در حال حاضر از کنترلهای حسگر قوی استفاده میکند، EVER-POWER به طور فعال در حال تحقیق در مورد ادغام ISOBUS برای تکرارهای آینده است تا امکان ارتباط مستقیم عدلبند با تراکتور را فراهم کند، ویژگیای که به طور فزایندهای توسط کاربران تراکتورهای ممتاز مانند جان دیر و فندت درخواست میشود.

۹. درباره ما | قابلیتهای کارخانه EVER-POWER و سفارشیسازی OEM

شرکت ماشینآلات اور-پاور (EVER-POWER Machinery Co., Ltd.) فقط یک مونتاژکار نیست؛ ما یک تولیدکننده جامع هستیم که در منطقه توسعه اقتصادی و فناوری ملی واقع شده است. تأسیسات ما ۳۲۰۰۰ متر مربع مساحت دارد و مجهز به ابزارهای پیشرفته تولید هوشمند، از جمله برشدهندههای لیزری CNC، خطوط جوشکاری رباتیک و سیستمهای پوشش پودری الکترواستاتیک است. این ادغام عمودی به ما امکان ارائه خدمات بینظیر را میدهد. خدمات نصب و سفارشی سازی.

برای شرکای ما در کره جنوبی و فراتر از آن، گزینههای سفارشیسازی عمیقی برای S9000 ارائه میدهیم. این موارد شامل موارد زیر است:

- تطبیق رنگ: رنگآمیزی سفارشی متناسب با برند نمایندگی شما (مثلاً آبی LS، قرمز TYM).

- اصلاح قلاب: تطبیق حلقه کششی با استانداردهای خاص میل مهار مورد استفاده در مناطق محلی.

- تطبیق هیدرولیک: سفارشیسازی کوپلینگهای هیدرولیکی برای مطابقت با نرخهای جریان خاص و انواع اتصال مدلهای قدیمیتر تراکتور که اغلب در مناطق روستایی یافت میشوند.

- محافظت تقویتشده: اضافه کردن صفحات محافظ اضافی برای محافظت از شاسی در مناطق صخرهای.

۱۰. نمونه موفقیت مشتری: برداشت با راندمان بالا در استان چانگچئونگ

«ما از S9000 برای شالیزارهای برنج خود استفاده کردهایم و انعطافپذیری سیستم اتصال آن تفاوت چشمگیری ایجاد کرده است. قابلیت تنظیم شیب 30 درجه و چرخش 100 درجه به ما این امکان را میدهد که بدون هیچ مشکلی در مزارع تپهای خود به راحتی کار کنیم. این دستگاه به طور چشمگیری در زمان صرفهجویی کرده و تراکم بستهها برای سیلو بسیار عالی است!»

--- سو-جین از جئولابوک-دو، کره جنوبی«دستگاه S9000 در ساخت عدلهای متراکمتر، یک هیولا است. ما از آن برای ساقههای ذرت استفاده میکنیم و سیستم دو زنجیرهای 20A واقعاً عدلها را به خوبی فشرده میکند. وزن اضافه شده به آن پایداری زیادی میدهد و ما شاهد افزایش قابل توجهی در بهرهوری خود بودهایم. این دستگاه برای دوام ساخته شده است و خوشحالم که روی آن سرمایهگذاری کردیم.»

---تام از کالیفرنیا، آمریکا«با توجه به زندگی در منطقهای با مقررات سختگیرانه زیستمحیطی، S9000 نجاتبخش بوده است. به لطف سیستم تغذیه قدرتمند Axial Flow، دیگر نیازی به سوزاندن کاه برنج خود نداریم. این سیستم کاه خیس را به طور کامل مدیریت میکند و ما میتوانیم مزارع خود را در کمترین زمان پاکسازی کنیم، در حالی که از قانون حفاظت از هوای پاک نیز پیروی میکنیم.»

---مین هو از Chungcheongnam-do، کره جنوبی«در مزرعه گاوداری ما، کیفیت علوفه سیلو شده کلیدی است و S9000 فراتر از انتظارات ما عمل کرده است. کنترل تراکم بسته تضمین میکند که هر بسته برای تخمیر مناسب است. استفاده از آن آسان است و با عملکرد پرسرعت آن، ما توانستهایم بستهبندی را با کارایی بیشتری انجام دهیم و کیفیت خوراک خود را بهبود بخشیم.»

--- یوهان از کیپ غربی، آفریقای جنوبی«دستگاه S9000 به عملیات گندم زمستانی ما کمک بزرگی کرده است. این دستگاه قدرتمند است و کاه سفت و متراکم را به راحتی جابجا میکند. ما شاهد بهبود کیفیت عدل و زمان سریعتر پاکسازی مزرعه بودهایم. به علاوه، سازگاری با تراکتورهای محلی ما به این معنی است که لازم نیست نگران هیچ گونه مشکل فنی باشیم.»

---میخائیل از کراسنودار، روسیه

۱۱. قطعات قابل تعویض

۱۱.۱ گیربکس:

مدلهای سازگار: سری EP-Round (دستگاه بستهبندی گرد، نسبت انتقال ۱:۲، سازگار با شفت ۶ خار ۳۵ میلیمتری).

کاربرد: انتقال قدرت PTO به مکانیزم عدلبندی، مناسب برای نیوهلند ۶۳۰ یا جان دیر ۵۳۵. پارامترها: گشتاور > ۵۰۰ نیوتن متر، صرفهجویی در مصرف سوخت ۲۰۱TP4T.

چرا این گیربکس را انتخاب کنید: اندازه قابل تنظیم (قابل کاهش به ۲۵۰-۳۰۰ میلیمتر)، مقاوم در برابر آلایندههای چسبناک (بخار لاستیک)، درجه حفاظت IP65. شفت PTO:

مدلهای سازگار: سری EP-PTO (اسپلین Z6 با قطر ۱-۳/۸ اینچ، طول قابل تنظیم ۶۰۰-۱۲۰۰ میلیمتر).

کاربرد: اتصال تراکتور به درایو اصلی بیلر، مناسب برای نوع 9YG-1.0C. راندمان انتقال گشتاور >95%، سازگار با فلنجهای SAE/EURO.

11.2 زنجیر و چرخ دنده ها:

مدلهای سازگار: ANSI #50/#60 زنجیربا چرخدنده EP-Sprocket (گام ۱۲.۷-۱۹.۰۵ میلیمتر، قطر غلتک ۱۰-۱۲ میلیمتر).

کاربرد: مورد استفاده در تسمه نقاله یا مکانیزمهای اتصال، مناسب برای انتقال کاه به صورت مربع/گرد. عرض 25-40 میلیمتر، جنس فولاد مقاوم در برابر سایش.

۱۱.۳ کوپلینگها:

مدلهای سازگار: سری EP-Coupling 200 (گشتاور تطبیقی ۵۰۰-۱۰۰۰ نیوتن متر).کاربرد: گیربکس را به غلتک عدلبندی متصل میکند، لرزش را کاهش میدهد.

11.4 سیلندر هیدرولیک:

سیلندر هیدرولیک: سری EP-HC (قطر داخلی ۵۰-۱۰۰ میلیمتر، کورس ۳۰۰-۶۰۰ میلیمتر)، مناسب برای بلند کردن عدل.بلبرینگ و آببند: بلبرینگ 6208-2RS، طول عمر L10 >10000 ساعت، آببند ضد گرد و غبار.جدول سازگاری: کاملاً قابل تعویض با Comer 250T (تطبیق گشتاور، فقط 35% با قیمت)؛ فلنج با الگوی PTO 4-Bolt آمریکای شمالی مطابقت دارد.

۱۲. سایر محصولات در همان سری (۲.۲۴D)

سوالات متداول (FAQ)

سوال ۱. چرا گره کششی قابل تنظیم مدل S9000 برای شالیزارهای کرهای مهم است؟

سوال ۲. سیستم زنجیر دو طرفه ۲۰A چگونه کیفیت بسته بندی علوفه سیلو شده را بهبود میبخشد؟

س ۳. آیا دستگاه 9YG-2.24D S9000 میتواند کاه برنج مرطوب را بدون گرفتگی در طول فصل بارانهای موسمی جابجا کند؟

سوال ۴. توان توصیه شده تراکتور برای عملکرد موثر S9000 در سربالاییها چقدر است؟

سوال ۵. آیا تراکتور 9YG-2.24D S9000 با تراکتورهای LS Mtron و TYM سازگار است؟

س۶. ابعاد حمل و نقل چقدر است و آیا جابجایی بین مزارع کوچک آسان است؟

سوال ۷. این دستگاه چگونه به کشاورزان کمک میکند تا ممنوعیت سوزاندن کاه و کلش در کره را رعایت کنند؟

س۸. آیا شرکت EVER-POWER قطعات یدکی مانند زنجیرهای ۲۰A و دندانههای وانت را در کره ارائه میدهد؟

Q9. طول عمر مورد انتظار غلتکها در مقایسه با دستگاههای بستهبندی تسمهای چقدر است؟

سوال ۱۰: آیا میتوانم رنگ دستگاه بستهبندی علوفه را متناسب با تراکتورهای فعلیام تغییر دهم؟

تدوینگر: PXY