Descrizione

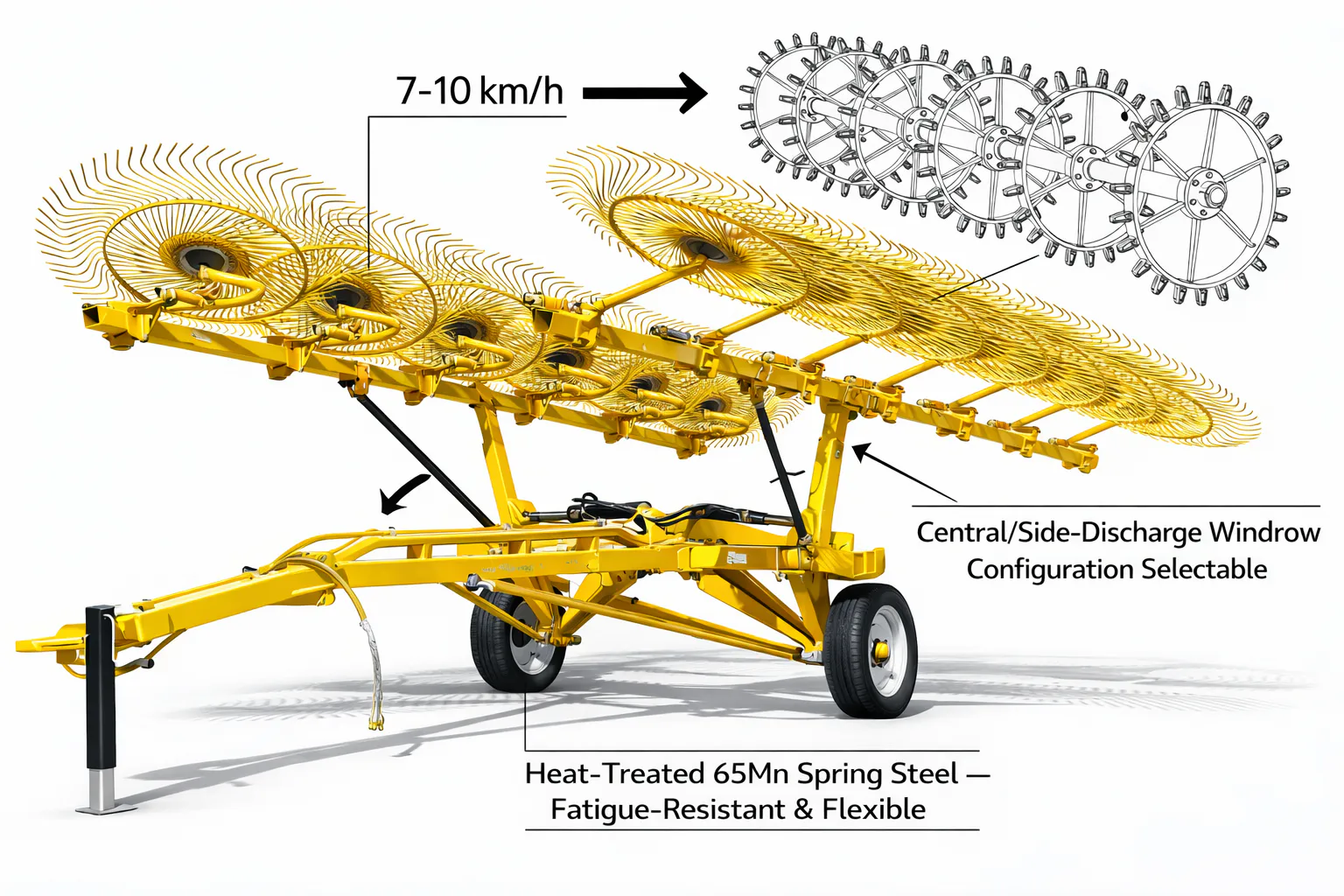

1. Technical Specifications: EP-9LZ-6.0 Disc-Type Hay Rake

| Serial No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | EP-9LZ-6.0 Finger Disk Type Hay Rake |

| 2 | Structure Form | / | Finger Wheel Type |

| 3 | Attachment Method | / | Towed Type |

| 4 | Model Specification | / | 9LZ-6.0 |

| 5 | Required Power | kW | ≥25.73 |

| 6 | Operating Dimension (L×W×H) | mm | 7600×6800×1500 |

| 7 | Structural Mass | kg | 1200 |

| 8 | Raking Width | m | 6 |

| 9 | Working Speed | km/h | 7~10 |

| 10 | Transport Speed | km/h | ≤18 |

| 11 | Number of Finger Disks | pcs | 12 |

| 12 | Number of Raking Teeth | pcs | 720 (12 disks × 60 teeth/disk) |

| 13 | Operator Count | person | 1 |

| 14 | Hay Windrow Width | mm | 800–1400 |

| 15 | Missed Raking Rate | / | ≤2% |

| 16 | Production Rate | hm²/h | 4.2–6 |

View All Products Categories

2. Revolutionizing Forage Harvest: The 9LZ-6.0 Disc-Type Hay Rake

In the high-stakes environment of modern agriculture, particularly within the intensive livestock farming sectors of South Korea’s Jeollabuk-do and Chungcheongnam-do provinces, the efficiency of forage harvesting is directly linked to profitability. The 9LZ-6.0 Disc-type hay rake (also known as a finger-wheel rake) represents the pinnacle of ground-driven harvesting technology. Unlike complex PTO-driven rotary rakes that consume significant tractor horsepower, this 12-wheel giant utilizes the forward momentum of the tractor to gently turn and windrow hay. With a massive working width of 6.0 meters, it is engineered to cover vast acreages of Italian Ryegrass (IRG), alfalfa, and rice straw with minimal fuel consumption.

The structural integrity of the 9LZ-6.0 is built to withstand the rigors of uneven terrain often found in reclaimed agricultural lands. It features a heavy-duty chassis supported by independent suspension on each rake wheel, allowing for superior ground contouring. This “floating” capability ensures that the tines pick up the crop cleanly without engaging the soil, thereby reducing ash content in the final silage or bale. For Korean farmers who often struggle with labor shortages, the high productivity rate of 4.2 to 6.0 hectares per hour means that a single operator can do the work of three smaller machines. Furthermore, the hydraulic lifting mechanism allows for seamless transition between working and transport modes, making it easy to navigate narrow rural roads between paddy fields.

3. Engineering Excellence: Working Principles, Materials, and Application Scenarios

The operational heart of the 9LZ-6.0 lies in its ground-driven finger-wheel design. Unlike a rotary hay rake which requires a PTO connection and gearboxes, the 9LZ-6.0 is purely traction-based. It features 12 individual finger wheels, each equipped with 60 high-tensile spring steel tines. As the rake moves forward at speeds of 7 to 10 km/h, the angle of the wheels relative to the direction of travel causes them to rotate. This rotation gently sweeps the crop diagonally across the width of the machine, consolidating it into a central or side windrow (depending on configuration). This durability is essential when harvesting rice straw in dried paddy fields, where uneven ground is common.

Regarding application scenarios, the 9LZ-6.0 is incredibly versatile but excels in specific conditions. It is the ideal tool for “Speed Raking” in large, open fields of dry hay or wilted silage. In the context of the South Korean market, it is particularly effective for managing heavy rice straw residues after the combine harvester has passed. The rake’s ability to flip and fluff the straw promotes rapid air circulation, reducing moisture content to levels suitable for round baling. However, operators should note that while it is robust, it is distinct from a wheel hay rake designed for heavy wet silage muck; the 9LZ-6.0 is optimized for speed and efficiency in curing crops. Its low power requirement (minimum 35 HP) makes it compatible with older or smaller utility tractors, maximizing the utility of your existing machinery fleet.

4. Global Standards and Regional Regulatory Compliance (Korea Focus)

Navigating the regulatory landscape of agricultural machinery is paramount for ensuring operator safety and legal compliance. The 9LZ-6.0 Disc-type hay rake is manufactured in strict adherence to international safety standards, specifically aligning with ISO 4254-10 (Agricultural machinery – Safety – Part 10: Rotary tedders and rakes). This standard governs the guarding of moving parts, stability during transport, and hitch integrity. For our valued clients in South Korea, we ensure that our equipment meets the rigorous testing criteria established by the Korea Agricultural Technology Promotion Agency (KOAT). This includes compliance with road transport regulations regarding width and lighting.

Customer Success Story: Efficiency Gains in Gimje Plains

Carlos, Agricultural Manager – Colombia

“We’ve been using the 9LZ-6.0 in our alfalfa fields here in Meta, and the efficiency is incredible. The 6-meter working width really saves us time compared to other models we’ve tried. Plus, it’s so simple to use with the ground-driven system — no need for complex PTO setups. It handles our heavy rice straw perfectly, and the windrows are always well-formed and dry. Definitely worth the investment!”

Jinwoo, Ranch Owner – South Korea

“As a dairy farmer in Jeollabuk-do, I needed something reliable and easy to maintain. The 9LZ-6.0 has been amazing. It’s perfect for handling our rice straw after harvest. The rake’s wide 6-meter span allows me to finish large fields in no time. It’s simple, energy-efficient, and the low-power requirement makes it ideal for my 45HP tractor. I can’t imagine working without it now.”

Miguel, Livestock Farm Owner – Spain

“Working in the rolling hills of Andalucia, I was looking for a hay rake that could handle our varied terrain. The 9LZ-6.0 performs fantastically. The hydraulic lift system makes it easy to adjust the rake, and the flexibility of the tines means I get a clean cut every time without disturbing the soil. It’s the ideal machine for our farm, especially during the dry hay season. Highly recommend it!”

Chun, Agricultural Co-op Leader – China

“We’ve been using the 9LZ-6.0 for multiple cooperative farms in Henan, and it’s proven to be highly effective. The rake’s design, with 12 discs and 720 tines, provides excellent coverage. It works incredibly well for rice straw collection, helping us manage large areas efficiently. The low missed raking rate is crucial, and the hydraulic folding system makes transport between fields a breeze.”

8. Replaceable parts

8.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection.8.2 PTO SHAFT:

Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

8.3 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

8.4 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

8.5 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

Frequently Asked Questions (FAQ)

Q1. What is the current disc type hay rake price for the 9LZ-6.0 model delivered to Busan, Korea?

A1. The price fluctuates based on steel costs and shipping rates. However, we offer highly competitive CIF Busan pricing. Please click “Get a Quote” for a precise estimate tailored to your order volume and location.

Q2. Is the 9LZ-6.0 compatible with my 40HP LS Tractor?

A2. Yes, absolutely. The 9LZ-6.0 requires a minimum of 25.73 kW (approx. 35 HP). Your 40HP LS tractor is perfectly suited to tow and operate this rake efficiently.

Q3. Where can I buy replacement disc type hay rake parts if a tine breaks?

A3. We supply a comprehensive spare parts kit with every machine. Additionally, our tines use standard dimensions (65Mn steel), making them compatible with many generic parts available in local Korean agricultural supply stores.

Q4. How does this wheel hay rake compare to a rotary hay rake for wet silage?

A4. For very heavy, wet muck silage, a rotary rake is often preferred. However, for semi-dry hay, straw, and general forage, the 9LZ-6.0 is faster and cheaper. It can handle green crop, but operates best on wilted or dry material.

Q5. Can I find a disc type hay rake for sale near me in South Korea?

A5. We ship directly from our factory to major Korean ports (Incheon, Busan, Pyeongtaek). We also have partnerships with local dealers. Contact us to find the nearest distributor or to arrange direct shipping.

Q6. What is the transport width of the machine when folded?

A6. When hydraulically folded for transport, the machine width is approximately 2.4 meters. This complies with most road safety regulations for agricultural machinery in South Korea and globally.

Q7. Are there different types of hay rakes available if I need a smaller size?

A7. Yes, the 9LZ series comes in various sizes. The 9LZ-6.0 has 12 discs, but we also offer models with 9 discs for smaller fields. Check our “Products Categories” for the full range.

Q8. How do I adjust the windrow width for my round baler?

A8. The windrow width is adjustable between 800mm and 1400mm. This is done by changing the angle of the rear frame section, allowing you to match the swath perfectly to the pickup width of your baler.

Q9. Does the machine come with a warranty for the hydraulic cylinders?

A9. Yes, we provide a 12-month standard warranty on the main frame and hydraulic components against manufacturing defects. We stand by the quality of our equipment.

Q10. Can you customize the paint color to match my Kubota tractor?

A10. Yes, we offer OEM customization. If you provide the specific RAL color code for Kubota Orange, we can paint the machine to match your fleet perfectly before shipping.

Editor: PXY