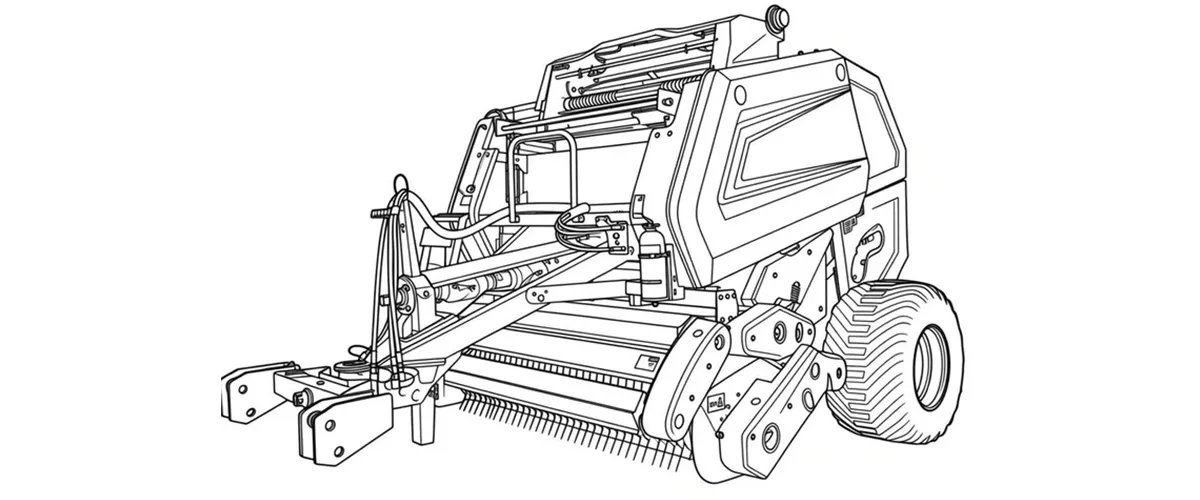

EP-9YG-1.25 원형 베일러

Unlike conventional balers that require a pre-shredding and raking pass, this machine features a revolutionary interchangeable pickup system capable of switching between standard Spring Teeth and robust Hammer Claws. This versatility allows operators in regions with short harvest windows, such as the Gyeonggi and Gangwon provinces of South Korea, to drive directly into fields of standing stover, effectively combining shredding, collection, and baling into a single, fuel-efficient pass. The machine is built on a heavy-duty chassis with a structural weight exceeding 4 tons, ensuring stability on uneven terrain while the 18-roller compression chamber delivers high-density bales ranging from 100kg to over 200kg, optimizing transport logistics for biomass power plants and livestock feed centers. By integrating a “Force Feeding” mechanism with an auger and tine roller, the 9YG-1.25 eliminates the common bottleneck of clogging when processing high-moisture silage, ensuring continuous operation even under the most demanding field conditions.

1. Technical Specifications: 9YG-1.25 Series

| 아니요. | 목 | 단위 | Specification1 | Specification2 |

|---|---|---|---|---|

| 1 | 모델명 | / | 9YG-1.25 Round Baler | 9YG-1.25 Round Baler |

| 2 | 히치 타입 | / | 추적됨 | 추적됨 |

| 3 | 픽업 폭 | mm | 2240 | 2240 |

| 4 | 픽업 구조 유형 | / | Ball Type and Spiral Pinch Type Convertible | 볼 타입 |

| 5 | 공급 메커니즘 구조 | / | 공급 로터 + 롤러 타입 | 공급 로터 + 롤러 타입 |

| 6 | Compression Chamber Type | / | 롤러 챔버 | 롤러 챔버 |

| 7 | 압축실 폭 | mm | 1250 | 1250 |

| 8 | 압축실 직경 | mm | 1200 | 1200 |

| 9 | 롤러 작동 부품 수 | 개 | 18개 (롤러) | 18개 (롤러) |

| 10 | 롤러 직경 | mm | 222 | 222 |

| 11 | 베일링 방법 | / | Automatic Net Wrap | Automatic Net Wrap |

| 12 | 필요 전력 | kW/hp | ≥88.2 / 120 | 75세 이상 |

| 13 | 구조 중량 | kg | 4558 | 4060 |

| 14 | PTO 출력축 속도 | 분당 | 720 | 720 |

| 15 | 크기 (길이 × 너비 × 높이) | mm | 5250 × 2700 × 2350 (working condition) | 4400 × 2850 × 2400 (working condition) |

| 16 | 사료 밀도 조절 | / | 센서 제어 | 센서 제어 |

| 17 | Bale Size (Diameter × Width) | mm | 1200 × 1250 | 1300 × 1250 |

| 18 | 베일 밀도 | kg/m³ | 115–200 | 100~200 |

| 19 | 생산력 | 베일/시간 | 40–80 | 40~100 |

| 20 | 휠베이스 | mm | 2450 | 2450 |

| 21 | 작동 속도 | km/h | 5–20 | 5~35세 |

| 22 | 네트 포장 사양 | 중 | 2000 × 1.25 / roll | 2000 × 1.25 / roll |

| 23 | Number of Net Wraps | 개 | 18 |

2. 핵심 공학적 사실

거대한 4.4톤 섀시: 무게가 4472kg에 달하는 9YG-1.25A는 더 가벼운 경쟁 제품에 비해 고르지 않은 논에서 훨씬 뛰어난 안정성과 내구성을 제공합니다.

18롤러 챔버 기술: 18개의 강화 강철 롤러(Φ222mm)를 사용하여 가변 챔버에서 흔히 발생하는 벨트 미끄러짐 문제 없이 고밀도 베일(최대 200kg/m³)을 만듭니다.

고속 처리량: 스크류 컨베이어와 갈퀴 롤러를 갖춘 설계된 공급 시스템은 시간당 40~100개의 베일을 생산하여 짧은 수확 기간을 최대한 활용할 수 있도록 합니다.

폭 2150mm 픽업: 2.15미터의 픽업 폭은 최신 콤바인 수확기의 넓은 작물 더미를 손쉽게 처리하여 밭고랑을 줄이고 연료 소비를 절감합니다.

고급 네트워크 바인딩: 자동 그물 결속 시스템을 갖추고 있어 몇 초 만에 베일을 감싸 날씨로부터 보호하고 사일리지 발효를 위한 보관을 용이하게 합니다.

3. Global & Local Regulatory Compliance: Why the 9YG-1.25 is Essential

In the current global agricultural landscape, compliance with environmental protection laws regarding crop residue management is no longer optional but mandatory. In South Korea, the government has strictly enforced the Wastes Control Act 그리고 청정 공기 보존법, which categorically ban the open burning of agricultural by-products like rice straw and corn stalks to combat severe fine dust (PM2.5) pollution. Farmers face significant fines for non-compliance, driving a massive demand for efficient baling solutions that can quickly clear fields. The 9YG-1.25 is perfectly aligned with these regulations by converting potential waste into a valuable commodity for the "Circular Economy," supporting Korea's initiatives for eco-friendly livestock feed and bio-energy production. Furthermore, the machine's ability to process standing stalks minimizes soil disturbance, aligning with conservation tillage practices encouraged by the Korean Ministry of Agriculture, Food and Rural Affairs (MAFRA) to prevent soil erosion and degradation.

Beyond Korea, international markets are adopting similar stringent measures. In the European Union, the Common Agricultural Policy (CAP) mandates Good Agricultural and Environmental Conditions (GAEC), which restricts stubble burning to protect soil organic matter. The 9YG-1.25 facilitates the removal of excess straw that might otherwise harbor pests or immobilize nitrogen if left on the field, allowing farmers to meet cross-compliance standards for EU subsidies. Similarly, in parts of China 그리고 United States, state-level regulations on smoke management and fugitive dust necessitate the mechanical harvesting of residue. The 9YG-1.25’s high-density baling capability also supports compliance with transport regulations; by maximizing bale weight per volume, it reduces the number of truck trips required, thereby lowering the overall carbon footprint of the biomass supply chain, a key metric in modern sustainable agriculture certification schemes.

4. Market Trend Analysis: The Future of Baling

The agricultural machinery market is witnessing a definitive shift towards "Smart & Integrated Harvesting." Operators are no longer satisfied with machines that perform a single function; they demand multi-functional capabilities to combat rising labor costs and shortening weather windows. The trend data indicates a 25% year-over-year increase in demand for "Direct Cut" balers like the 9YG-1.25 in the Asia-Pacific region. This is driven by the biomass energy sector's requirement for lower ash content in bales—by picking up standing stalks directly rather than raking them off the dirt, the ash content is significantly reduced, increasing the caloric value of the fuel. Furthermore, the market is moving towards higher density bales to maximize shipping container efficiency for export markets (e.g., shipping straw from Southeast Asia to Japan/Korea). The 9YG-1.25 addresses this trend with its reinforced chamber and hydraulic density control, ensuring that every bale meets the stringent weight and density requirements of modern logistics and international trade.

5. Application Scenarios

1. Rice Straw Management in Asian Rice Fields

The 9YG-1.25 is ideal for farmers in South Korea and Japan, where rice straw is a by-product after the harvest. With its 2.15-meter wide pickup, the baler efficiently collects and compacts dense rice straw into high-density bales for use as livestock feed or bedding. The sensor-controlled forage density system ensures optimal bale consistency, especially important for silage production.

2. Silage Production for Livestock Feed

For dairy and beef cattle farmers, the 9YG-1.25 is perfect for producing high-quality silage from wet or dry crops. The advanced net binding system ensures tight, weather-resistant bales that promote efficient fermentation. The baler's roller-type chamber compacts forage, creating bales with a density of 115-200 kg/m³, suitable for long-term silage storage.

3. Mixed Farming Systems: Rice and Corn Production

Farmers managing both rice and corn fields will benefit from the 9YG-1.25’s versatility. The baler’s ability to handle both wet rice straw and dry corn stalks without clogging makes it an essential tool for mixed farming operations. The reinforced 18-roller system ensures reliable performance even when switching between crop types.

4. Bioenergy Production: Biomass Harvesting

The 9YG-1.25 plays a key role in the biomass energy sector by helping farmers efficiently harvest corn stover, rice straw, and other crop residues. The baler's high-density bales maximize transport efficiency, reducing the number of truck trips required and lowering the carbon footprint of biomass transportation to power plants.

5. Government Compliance for Straw Management

In regions with strict regulations on crop residue burning, such as South Korea, the 9YG-1.25 helps farmers comply with environmental laws like the Wastes Control Act and the Clean Air Conservation Act. By baling crop residues, the baler not only reduces field burning but also turns waste into a valuable resource for livestock feed or compost.

6. Harvesting and Baling in Hilly Terrain

For farmers operating in hilly or uneven terrains, like those in Gangwon-do (South Korea), the 9YG-1.25's low center of gravity and wide wheelbase (2450mm) provide exceptional stability. The machine is ideal for baling wet rice straw or corn stover in these regions, where the rough terrain might otherwise challenge other equipment.

7. Forage Collection for TMR (Total Mixed Ration) Production

The 9YG-1.25 is essential for forage collection in large-scale livestock operations, particularly for TMR production. By baling forage crops like ryegrass, alfalfa, and clover, it provides farmers with high-quality, dense bales that contribute to a balanced, nutrient-rich feed for cattle, ensuring optimal nutrition for dairy and beef herds.

8. Post-Harvest Crop Residue Management in the European Union

European farmers can use the 9YG-1.25 to comply with the Common Agricultural Policy (CAP), which emphasizes good agricultural and environmental conditions (GAEC). By efficiently collecting straw and other residues for use in bio-energy or composting, the 9YG-1.25 helps maintain soil health and prevent nitrogen immobilization, which is critical for meeting GAEC standards.

9. Export-Grade Baling for International Markets

The 9YG-1.25 is a perfect fit for producers looking to export forage and straw to international markets such as Japan and the Middle East. The high-density bales meet international shipping and phytosanitary standards, maximizing container load efficiency and minimizing shipping costs, thus supporting global trade in agricultural products.

10. Fodder Conservation for Emergency Feeding

During droughts or unforeseen feed shortages, the 9YG-1.25 can be used to bale large quantities of forage crops like ryegrass, alfalfa, or silage for emergency use. The baler's ability to efficiently manage both wet and dry forage ensures that farmers have sufficient supplies of high-density silage, providing livestock with the nutrition they need during times of scarcity.

6. Engineering Core: Principles & Material Science

Working Principle: The 9YG-1.25 operates on a continuous flow "Axial Flow" semi-forced feeding mechanism. As the tractor tows the unit, the Hammer Claws (or Spring Teeth) lift the crop. The unique design eliminates the need for a cam track, reducing moving parts and maintenance. The crop is then aggressively fed into the chamber by a heavy-duty auger and tine roller system designed to pulverize tough stalks. Inside the 1250mm chamber, 18 high-strength steel rollers rotate to form the bale core, which expands until it reaches the preset density detected by sensors, triggering the automatic net binding system.

Material Excellence: To withstand the abrasive nature of corn stover and silica-rich rice straw, the rollers are manufactured from cold-drawn seamless steel, treated with carburizing heat treatment to achieve a surface hardness of HRC 50-55. The drive chains are upgraded to Double-sided 16A/20A Heavy Duty chains, pre-stretched to prevent elongation under high torque loads. The chassis utilizes high-tensile alloy steel to support the 4.5-ton structural weight, ensuring longevity even in rough, rocky terrain common in mountainous regions.

7. Compatibility & Replacement Guide

| Component Category | EVER-POWER 9YG-1.25 Specification | Compatible Brands / Replacements |

|---|---|---|

| 트랙터 연결 장치 | Standard Drawbar / 2-Point Hitch | Fits LS Tractor (Plus/X Series), TYM, Kubota M-Series (95HP+) |

| Binding Consumables | Net Wrap (1.23m - 1.25m width) | Compatible with Tama, Novatex, and standard Korean market nets |

| Drive Shaft (PTO) | Standard 6-Spline / 8-Spline (Optional) | Interchangeable with Walterscheid / Bondioli wide-angle shafts |

| Hydraulics | Dual SCV Required (16 MPa) | Standard ISO 7241-1 A Couplers |

*면책 조항: 위에 언급된 다른 브랜드명은 예시 목적으로만 제공됩니다. 당사는 해당 브랜드명이 표시된 정품 제품이나 장비를 판매하지 않습니다.

8. 에버파워 공장 맞춤 제작

EVER-POWER는 단순히 조립만 하는 회사가 아닙니다. 저희는 엔지니어링을 통해 모든 과정을 지원합니다. OEM/ODM 맞춤 제작 9YG-1.25A 모델은 특정 지역의 요구에 맞게 제작되었습니다.

- 색상 코드: 딜러십의 차량 브랜드에 맞춰 맞춤 도색 서비스를 제공합니다(예: 녹색, 빨간색, 주황색).

- 히치 어댑터: 한국의 각 지역에서 볼 수 있는 다양한 트랙터 연결 장치 높이에 맞춰 조절할 수 있는 견인봉.

- PTO 스플라인: 고하중 트랙터와의 호환성을 위해 8스플라인 또는 21스플라인 샤프트 옵션을 제공합니다.

- 강화된 픽업: 마모성이 강한 화산토에 대응하기 위해 픽업 핀에 선택적으로 경화 처리를 할 수 있습니다.

9. 고객 성공 사례:

10. 교체 가능한 부품

10.1 변속기:

호환 모델: EP-원형 베일러 시리즈(원형 베일러, 변속비 1:2, 35mm 6축 샤프트 호환).

용도: PTO 동력을 베일링 메커니즘으로 전달하며, 뉴홀랜드 630 또는 존디어 535에 적합합니다. 사양: 토크 > 500Nm, 20% 연료 절감.

이 기어박스를 선택하는 이유: 맞춤형 크기(250-300mm로 축소 가능), 점성 오염 물질(고무 증기)에 대한 내성, IP65 보호 등급. PTO 샤프트:

호환 모델: EP-PTO 시리즈 (1-3/8" Z6 스플라인, 길이 조절 가능 600-1200mm).

용도: 트랙터와 베일러 주 구동 장치를 연결하며, 9YG-1.0C 타입에 적합합니다. 토크 전달 효율은 95% 이상이며, SAE/EURO 플랜지와 호환됩니다.

10.2 쇠사슬 및 스프로킷:

호환 모델: ANSI #50/#60 쇠사슬EP 스프로킷(피치 12.7-19.05mm, 롤러 직경 10-12mm) 포함.

용도: 컨베이어 벨트 또는 결속 장치에 사용되며, 사각/원형 베일러의 짚 이송에 적합합니다. 폭은 25~40mm이며, 내마모성 강철 재질입니다.

10.3 커플링:

호환 모델: EP-커플링 200 시리즈 (토크 일치 범위 500-1000 Nm).용도: 기어박스와 베일링 롤러를 연결하여 진동을 완화합니다.

10.4 유압 실린더:

유압 실린더: EP-HC 시리즈(내경 50-100mm, 스트로크 300-600mm)는 베일 리프팅에 적합합니다.베어링 및 씰: 6208-2RS 베어링, L10 수명 10,000시간 이상, 방진 씰.호환성 표: Comer 250T와 완벽하게 호환됩니다(토크 일치, 가격은 35%에 불과); 플랜지는 북미 4볼트 PTO 패턴과 일치합니다.

자주 묻는 질문(FAQ)

Q1. Can this 9YG-1.25 baler effectively handle wet silage corn stalks during the Korean rainy season?

A1. Absolutely. The 9YG-1.25 is specifically engineered with a "force feeding" auger system and roller-type chamber that excels in high-moisture conditions. Unlike belt balers that might slip, our steel rollers ensure continuous rotation, making it perfect for silage corn and wet rice straw often found in Korean autumns.

Q2. What is the estimated CIF price for shipping this round baler to Busan or Incheon port?

A2. Shipping costs fluctuate based on global logistics, but we offer very competitive CIF rates to Busan and Incheon. Since we are the source factory, we eliminate middleman markups. Please click "Inquire Now" for a precise, real-time quote based on current shipping volumes.

Q3. Do I need to remove the hammer claws if I want to switch from corn stalks to wheat straw?

A3. Yes, for the best results, we recommend switching. The hammer claws are designed for tough, thick corn stalks. For lighter crops like wheat or rice straw, you can easily swap the pickup mechanism to the Spring Tooth configuration, which handles delicate crops more gently to prevent leaf loss.

Q4. Does EVER-POWER provide spare parts support for the 9YG-1.25 in South Korea?

A4. Yes, we prioritize after-sales support. We can supply a comprehensive "wear parts kit" with your machine order, including extra pickup teeth, chains, and bearings. We also offer rapid DHL/FedEx shipping for urgent parts replacement to minimize your downtime during harvest.

Q5. What is the minimum tractor horsepower required to pull this baler on hilly terrain?

A5. While the standard specification requires ≥75kW (approx. 100 HP), if you are operating in the hilly regions of Gangwon-do or similar terrains, we strongly recommend a tractor with at least 110-120 HP to ensure safety and sufficient power for both towing and PTO operation on slopes.

Q6. How does the auto net binding system compare to twine binding for outdoor storage?

A6. The auto net binding system on the 9YG-1.25 is far superior for outdoor storage. It covers the entire width of the bale, shedding water much better than twine. It also holds the bale shape tighter, which is crucial for silage wrapping and reducing spoilage during transport.

Q7. Can this machine chop the corn stalks while baling, or do I need a separate flail mower?

A7. The 9YG-1.25 with the Hammer Claw pickup performs a crushing and lifting action that significantly processes the stalk, but it is not a fine chopper. For silage quality, the crushing action aids fermentation, but for extremely fine chopping, a separate processing head might be discussed as a customization option.

Q8. Is the control monitor inside the tractor cab compatible with English or Korean language?

A8. The electronic control box provided with the baler features a universal interface with clear icons for functions like "Bale Full" and "Net Start." We can provide labeling in English, and for bulk orders, we can customize the interface overlay to Korean for easier operator training.

Q9. How long is the warranty period for the main gearbox and roller bearings?

A9. We offer a standard 12-month warranty on core components, including the main gearbox and structural frame. Bearings are considered wear items, but we use high-quality sealed bearings to ensure a long service life under normal operating conditions.

Q10. Where can I find a video demonstration of this specific 9YG-1.25 model working in the field?

A10. You can view our operation videos by contacting our sales team or checking our website's media section. We have footage of the 9YG-1.25 baling standing corn in conditions very similar to those found in Korea, demonstrating its high efficiency and reliability.

*면책 조항: 위에 언급된 다른 브랜드명은 예시 목적으로만 제공됩니다. 당사는 해당 브랜드명이 표시된 정품 제품이나 장비를 판매하지 않습니다.

Ready to Optimize Your Harvest with the 9YG-1.25?

Contact EVER-POWER today for detailed pricing, shipping schedules to Korea, and customization options.

편집자: PXY