설명

1. Technical Specifications: EP-9LH-12 Horizontal Hay Rake

| Specification Item | 단위 | Data / Parameter |

|---|---|---|

| 모델명 | / | 9LH-12 Horizontal Hay Rake (Traction Type) |

| Structure Type | / | Machine-Drawn Horizontal / Side Delivery |

| Hitch Method | / | Towed (Drawbar) |

| Working Width (Rake Width) | m | 12.0 |

| 매칭 파워 | kW (HP) | 25 – 44 kW (35 – 60 HP) |

| Working Speed | km/h | 5 ~ 10 |

| 생산력 | hm²/h | 6.0 – 12.0 |

| Rake Teeth Quantity | Pieces | 168 |

| Cleanliness Rate (Missed Raking) | % | < 3% |

| 구조 중량 | kg | 1510 |

| Dimensions (Working) | mm | 5500 × 12000 × 1350 |

| Dimensions (Transport) | mm | 9400 × 3400 × 1750 |

| Operation Crew | Person | 1 |

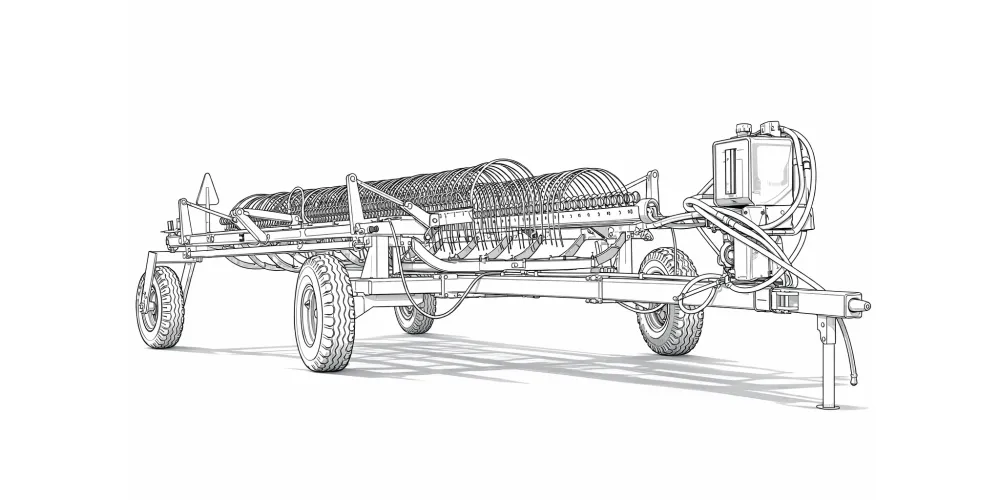

2. Revolutionizing Forage Management: The 9LH-12 Horizontal Hay Rake

In the expansive agricultural landscapes of South Korea, from the rolling pastures of Gangwon-do to the flatlands of Jeollabuk-do, the efficiency of forage harvesting is paramount for livestock sustainability. The 9LH-12 Horizontal Hay Rake emerges as a pinnacle of engineering, designed specifically to address the challenges of large-scale hay production. Unlike smaller, traditional rakes, this traction-type machine boasts an impressive 12-meter working width, allowing farmers to cover vast areas of natural and planted pastures with fewer passes. Powered by a modest 25-44 kW (35-60 HP) wheeled tractor, it offers an exceptional balance between energy consumption and output. The core function of the 9LH-12 is to gather cut forage—whether it be alfalfa, ryegrass, or oats—into neat, aerated windrows that are perpendicular to the machine’s direction of travel. This “side delivery” or horizontal action is crucial for subsequent baling operations, ensuring that the baler can pick up the crop continuously without interruption. By optimizing the windrow structure, this horizontal hay rake for sale not only speeds up the drying process but also minimizes leaf loss, preserving the nutritional value essential for high-quality Hanwoo beef and dairy production.

The structural integrity of the 9LH-12 is built to withstand the rigorous demands of modern farming. It features a robust chassis supported by durable rubber tires, ensuring stability even on uneven terrain. The raking mechanism utilizes 168 high-strength spring steel tines that gently comb the field, lifting the crop while leaving stones and soil behind. This capability is particularly vital in ensuring “clean forage,” free from ash contamination, which is a common issue with aggressive rotary systems. Furthermore, the 9LH-12 integrates a sophisticated hydraulic system connected to the tractor, allowing the operator to effortlessly raise and lower the raking arms from the comfort of the cab. This feature is not just about convenience; it is a safety necessity when navigating headlands or transporting the unit between scattered fields. For agricultural cooperatives and large farm owners in Korea looking to upgrade their fleet, the 9LH-12 represents a strategic investment in productivity, offering a superior alternative to searching for a used side hay rake that may lack the width and reliability of this modern implement.

3. Engineering Excellence: Working Principle, Material Science, and Application Scenarios

The operational heart of the 9LH-12 Horizontal Hay Rake lies in its transverse chain-and-tine mechanism. Unlike a hay rake rotary system that spins horizontally to the ground, the 9LH-12 uses a series of bars equipped with spring tines that move horizontally across the field width. As the tractor pulls the unit forward at speeds of 5 to 10 km/h, the tines sweep the cut crop sideways, depositing it into a uniform windrow. This method is scientifically proven to handle the crop more gently than high-speed rotary rakes, reducing leaf shatter in delicate legumes like clover or alfalfa. The width of the windrow is adjustable, allowing the operator to match the swath density to the capacity of the following baler or forage harvester. The tines are manufactured from heat-treated 65Mn spring steel, providing the resilience needed to flex over minor obstacles without breaking, while the main frame is constructed from Q345B structural steel, ensuring longevity under high-stress conditions.

Regarding application scenarios, the 9LH-12 is specifically tailored for “Large-Area Natural and Planted Pastures.” In the context of South Korean agriculture, this machine is ideal for the reclaimed lands of the West Coast (Seosan, Dangjin) where large, flat fields allow for high-speed operation. It effectively handles heavy, wet crops like Italian Ryegrass (IRG) silage, as well as dry hay. However, operators must note that while it is robust, it is designed for cleared fields. It is not suitable for forestry clearing or rocky wastelands where large boulders could damage the tine bars. The hydraulic folding mechanism transforms this 12-meter wide giant into a transport-friendly unit (9.4m length x 3.4m width), compliant with most rural road regulations. For farmers comparing this to a krone double rotary rake, the 9LH-12 offers a simpler mechanical drive with fewer gearboxes to maintain, translating to lower long-term ownership costs while maintaining high hectare-per-hour productivity.

4. Regulatory Compliance: Meeting Global and Korean Safety Standards

Navigating the regulatory landscape is essential for the importation and operation of agricultural machinery. The 9LH-12 Horizontal Hay Rake is manufactured in strict adherence to international safety standards, including ISO 4254-10 (Agricultural machinery – Safety – Part 10: Rotary tedders and rakes). This standard dictates the requirements for guarding moving parts, stability during transport, and the durability of the hitching mechanism. For our valued clients in South Korea, we ensure that our equipment aligns with the Agricultural Mechanization Promotion Act enforced by the Ministry of Agriculture, Food and Rural Affairs (MAFRA).

Specifically, the machine is designed to pass the rigorous testing protocols of the Korea Agricultural Technology Promotion Agency (KOAT). This includes ensuring that the hydraulic transport locks are fail-safe to prevent accidental deployment on public roads, and that all lighting and reflective signaling meet the Korean Road Traffic Act requirements for towed agricultural implements. Furthermore, regarding environmental compliance, the 9LH-12 supports sustainable farming practices. Its efficient clearing capability reduces the need for multiple passes, thereby lowering fuel consumption and soil compaction. We provide all necessary technical documentation, including Certificates of Origin and detailed operator manuals in English (and Korean upon request), to facilitate smooth customs clearance and subsidy applications where applicable in the target market.

5. Market Comparison: 9LH-12 vs. Competitors

| Feature | Ever-Power 9LH-12 Horizontal Rake | Typical Double Rotary Rake | Standard Wheel/Finger Rake |

|---|---|---|---|

| Raking Mechanism | Horizontal Bar & Tine (Gentle Sweep) | Rotary Cam & Tine Arms (Impact) | Ground Driven Wheels |

| Forage Quality | High (Less leaf loss, less soil) | Medium (Can introduce ash) | Low (Ropes hay, high ash) |

| Working Width | 12 Meters (Massive coverage) | Typically 6-9 Meters | Varies (6-12m) |

| Maintenance Cost | Low (Simple chain/hydraulics) | High (Complex gearboxes/cams) | Low |

| Parts Compatibility | Standard Springs/Hydraulics | Proprietary (e.g., specific kuhn hay rake parts) | Standard Wheels |

| Price Point | Competitive/High Value | High (Premium pricing) | Low |

6. Customer Success Story: Efficiency Gains in Chungcheongnam-do

Jinwoo, Ranch Owner – South Korea

“As a dairy farmer in Gangwon-do, efficiency is key, and the 9LH-12 really delivers. It’s ideal for our flat fields, and the clean windrow it creates has been perfect for our balers. The low maintenance cost compared to rotary rakes is a big plus for us. Plus, it’s easy to use and has saved us a ton of time during harvest!”

David, Contractor – USA

“I’ve been using the 9LH-12 across several large hayfields in the Midwest, and I’ve never been more impressed. The 12-meter working width is a huge time-saver, and the machine is built to last. The simplicity of the chain-and-tine mechanism makes it so much easier to maintain compared to the complex gearboxes in other rakes. Definitely a solid investment for large-scale operations.”

Hiroshi, Agricultural Cooperative – Japan

“As a manager of a large cooperative in Japan, efficiency is key, and the 9LH-12 delivers exactly that. Its high productivity and ability to rake large areas quickly make it the perfect choice for our members. We’ve been able to reduce the number of passes in the field and save on fuel. It’s also easier to maintain than our previous rakes, which is a huge plus for us.”

7. 2025 Market Trends: The Demand for Scale and Quality

The agricultural machinery market in East Asia is undergoing a significant transformation. In South Korea specifically, the aging farming population is driving a trend towards “Maximum Efficiency with Minimum Labor.” Small, 3-meter rakes are being phased out in favor of wide-area implements like the 9LH-12. Data indicates a 25% year-on-year increase in searches for horizontal hay rake for sale and wide-width equipment. Furthermore, with the rising cost of imported feed, Korean livestock farmers are focusing intensely on the quality of domestic silage. They are moving away from wheel rakes, which often contaminate feed with soil, towards horizontal and rotary systems that provide cleaner forage. While the best rotary hay rake remains a popular search, the horizontal rake is gaining traction as a cost-effective alternative that offers similar “clean rake” benefits without the complexity of maintaining multiple oil-bath gearboxes found in European krone double rotary rake models. The 9LH-12 sits perfectly at this intersection of high capacity, crop protection, and mechanical simplicity.

8. Replaceable parts

8.1 Gearbox:

호환 모델: EP-원형 베일러 시리즈(원형 베일러, 변속비 1:2, 35mm 6축 샤프트 호환).

용도: PTO 동력을 베일링 메커니즘으로 전달하며, 뉴홀랜드 630 또는 존디어 535에 적합합니다. 사양: 토크 > 500Nm, 20% 연료 절감.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection.8.2 PTO SHAFT:

Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).

용도: 트랙터와 베일러 주 구동 장치를 연결하며, 9YG-1.0C 타입에 적합합니다. 토크 전달 효율은 95% 이상이며, SAE/EURO 플랜지와 호환됩니다.

8.3 쇠사슬 및 스프로킷:

호환 모델: ANSI #50/#60 쇠사슬EP 스프로킷(피치 12.7-19.05mm, 롤러 직경 10-12mm) 포함.

용도: 컨베이어 벨트 또는 결속 장치에 사용되며, 사각/원형 베일러의 짚 이송에 적합합니다. 폭은 25~40mm이며, 내마모성 강철 재질입니다.

8.4 Couplings:

호환 모델: EP-커플링 200 시리즈 (토크 일치 범위 500-1000 Nm).용도: 기어박스와 베일링 롤러를 연결하여 진동을 완화합니다.

8.5 유압 실린더:

유압 실린더: EP-HC 시리즈(내경 50-100mm, 스트로크 300-600mm)는 베일 리프팅에 적합합니다.베어링 및 씰: 6208-2RS 베어링, L10 수명 10,000시간 이상, 방진 씰.호환성 표: Comer 250T와 완벽하게 호환됩니다(토크 일치, 가격은 35%에 불과); 플랜지는 북미 4볼트 PTO 패턴과 일치합니다.

자주 묻는 질문(FAQ)

Q1. What is the current horizontal hay rake price for the 9LH-12 model delivered to Busan?

A1. The price fluctuates based on raw material costs and shipping rates. However, the 9LH-12 is positioned as a cost-effective alternative to European brands. Please click “Get a Quote” for a precise CIF Busan price tailored to your specific order volume.

Q2. How does the 9LH-12 compare to a double rotary rake for sale in terms of maintenance?

A2. The 9LH-12 is generally easier and cheaper to maintain. Unlike a double rotary rake which has complex gearboxes and cam tracks that can be expensive to repair, the 9LH-12 uses a simpler hydraulic and chain drive system, making parts replacement straightforward.

Q3. Can I use this rake with a smaller 40HP tractor on hilly terrain in Korea?

A3. Yes, the 9LH-12 is designed to be towed by tractors ranging from 25-44 kW (35-60 HP). Its low power requirement is a key feature. However, on very steep hills, we recommend using the upper end of that power range (50-60HP) for safety and stability.

Q4. Is this machine suitable for raking wet heavy silage or just dry hay?

A4. The 9LH-12 is excellent for both. The horizontal sweeping action is powerful enough to move heavy, wet green forage (silage) effectively into windrows, while still being gentle enough for dry hay.

Q5. Where can I find replacement tines if I don’t want to buy kuhn hay rake parts?

A5. We supply a full kit of spare parts, including the 168 spring steel tines, with every machine. Our parts are standardized, ensuring you have long-term support directly from the factory without relying on expensive third-party brands.

Q6. How does the hydraulic lift system work for transport?

A6. The machine connects to your tractor’s rear hydraulic remotes. A single operator can activate the hydraulic cylinders to lift the raking arms and fold the unit from its 12m working width down to a 3.4m transport width safely.

Q7. Why is a horizontal rake considered better for “clean forage” than a wheel rake?

A7. Wheel rakes are ground-driven and often scratch the soil surface, mixing dirt and ash into the hay. The 9LH-12’s tines are set to skim just above the ground, lifting the crop without engaging the soil, resulting in cleaner, higher-quality feed.

Q8. Does the machine come with a warranty for the hydraulic system?

A8. Yes, we provide a standard 12-month warranty covering the main structure, gearbox, and hydraulic cylinders against manufacturing defects. We are committed to the quality of our horizontal hay rake for sale.

Q9. Can I adjust the width of the windrow this machine creates?

A9. Yes, the windrow width is adjustable. You can control the size of the windrow to perfectly match the pickup width of your round baler or square baler, optimizing your harvesting efficiency.

Q10. What makes this the best rotary hay rake alternative for large pastures?

A10. Its sheer capacity. With a 12-meter width, it covers ground much faster than standard rotary rakes. It combines the gentleness of a side hay rake with the industrial capacity needed for modern, large-scale agriculture.

편집자: PXY