Pengikat Bulat EP-9YG-1.0

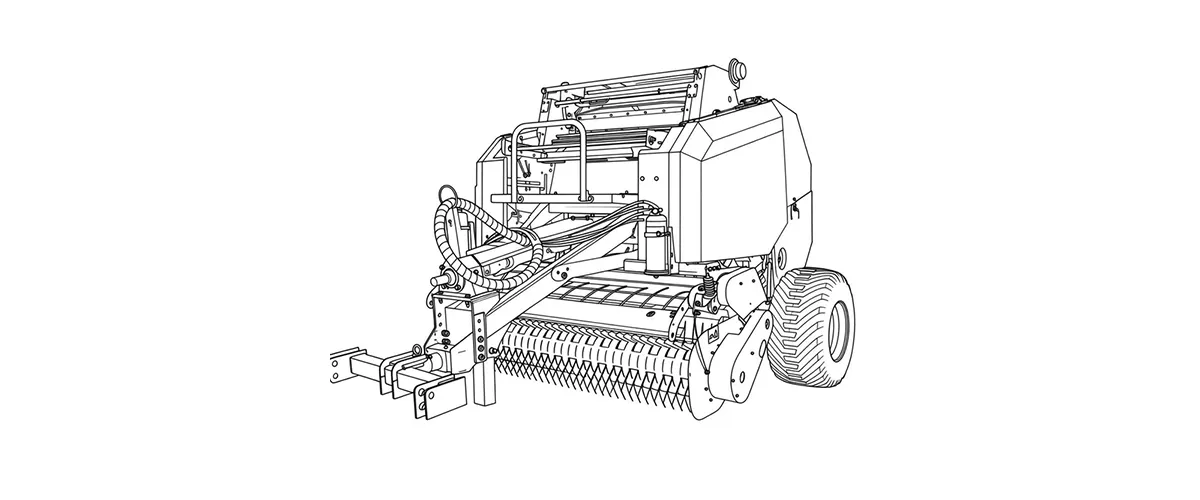

Yang Baler Bulat 9YG-1.0 oleh EVER-POWER mewakili anjakan paradigma dalam pengumpulan biojisim, yang direka khusus untuk landskap pertanian unik Korea Selatan dan Asia Timur. Menggunakan paten Mekanisme pemakanan separa paksa "Aliran Paksi" dan sistem pikap tanpa kam, mesin ini mengatasi kesesakan tradisional penggunaan kuasa dan penyumbatan, meningkatkan kecekapan operasi hampir 100% berbanding model konvensional. Dioptimumkan untuk traktor di 48-80 kW julat, ia menghasilkan bal berketumpatan tinggi yang boleh diurus dengan berat antara 100kg hingga 200kg, menjadikannya pilihan ideal untuk pengurusan padi plot kecil dan penuaian silaj jagung di kawasan berbukit.

1. Helaian Data Teknikal: Spesifikasi 9YG-1.0

| Nombor Item | Nama Parameter | Unit | Spesifikasi |

|---|---|---|---|

| 1 | Nama Model | / | Baler Bulat 9YG-1.0C |

| 2 | Jenis Halangan | / | Diikuti |

| 3 | Lebar Pengambilan | mm | 1900 |

| 4 | Jenis Struktur Pengambilan | / | Bilah + Gigi Pengambil + Penggelek |

| 5 | Mekanisme Pemakanan | / | Rotor Pemakanan + Penggelek |

| 6 | Lebar Ruang Mampatan | mm | 1000 |

| 7 | Diameter Ruang Mampatan | mm | Φ1000 |

| 8 | Bilangan Penggelek Mampatan | pcs | 16 (penggelek) |

| 9 | Diameter Penggelek | mm | Φ222 |

| 10 | Kaedah Pengikatan | / | Pengikatan Bersih |

| 11 | Kuasa Padanan | kw | 48~80 |

| 12 | Berat Struktur | kg | 2640 |

| 13 | Kelajuan PTO | r/min | 720 |

| 14 | Dimensi (P×L×T) | mm | 3750 × 2300 × 2020 |

| 15 | Kawalan Ketumpatan Makanan | / | Kawalan Sensor |

| 16 | Saiz Makanan (Diameter × Lebar) | mm | Φ1100 × 1000 |

| 17 | Ketumpatan Makanan | Kg/m³ | 115 ~ 200 |

| 18 | Produktiviti | Bal/j | 40 ~ 100 |

| 19 | Jarak roda | mm | 2045 |

| 20 | Kelajuan Operasi | Km/j | 5 ~ 20 |

| 21 | Spesifikasi Balutan Bersih | / | 2000m x 1.0m setiap gulung |

2. Fakta Kejuruteraan Kritikal

- Sistem Pemakanan Berpaten: Mempunyai struktur suapan separa paksa "Axial Flow" eksklusif yang menghapuskan keperluan pelindung sesondol, sekali gus mengurangkan kebarangkalian penyumbatan dengan ketara.

- Saiz Bale Optimum: Menghasilkan bal Φ1100×1000mm dengan ketumpatan sehingga 200 kg/m³, bersaiz sempurna untuk logistik standard Korea dan operasi pemberian makanan ternakan berskala kecil.

- Daya pemprosesan tinggi: Mampu memproses 40 hingga 100 bal sejam, memastikan pembersihan ladang yang cepat semasa tempoh penuaian yang ketat pada musim tengkujuh.

- Dewan Bertetulang: Dilengkapi dengan 16 penggelek keluli berkekuatan tinggi (Φ222mm) yang direka untuk mengendalikan sifat kasar jerami padi yang kaya dengan silika dan batang jagung yang keras.

- 🔹 Pengikatan Pintar: Sistem pengikatan jaring automatik bersepadu memastikan integriti bal semasa pengangkutan dan penyimpanan, mengurangkan kehilangan dan kerosakan tanaman.

3. Inovasi Teknologi: Kelebihan "Aliran Paksi" dalam Pembalakan Moden

Inovasi teras Pengikat Bulat 9YG-1.0 terletak pada seni bina pemakanan dan pemampatannya yang revolusioner, yang menangani cabaran khusus yang dihadapi oleh petani di wilayah seperti wilayah Chungcheong dan Jeolla di Korea Selatan. Tidak seperti pengikat tradisional yang bergantung pada trek sesondol yang kompleks—yang mudah haus dan tersekat ketika mengendalikan jerami padi yang basah dan melekit—9YG-1.0 menggunakan mekanisme pengambilan tanpa sesondol, bebas gelang pengawal. Penyederhanaan reka bentuk ini membolehkan pengambilan tanaman yang lebih langsung dan agresif, yang disebut pemberian separa paksa "Axial Flow". Dengan mengurangkan geseran dan rintangan pada titik pengambilan, mesin ini bukan sahaja mengurangkan keperluan kuasa kuda untuk traktor penunda tetapi juga meningkatkan jumlah pengambilan biojisim dengan ketara. Ini amat penting semasa menuai varieti jagung hasil tinggi atau petak jerami padi yang padat, di mana mesin tradisional sering menghadapi masalah "penyumbatan". Hasilnya ialah mesin yang menggandakan kecekapan operasi, membolehkan pengendali mengumpul lebih banyak ekar sejam dengan penggunaan bahan api yang lebih sedikit dan masa henti mekanikal. Sifat proprietari reka bentuk ini, dilindungi oleh hak harta intelek eksklusif.

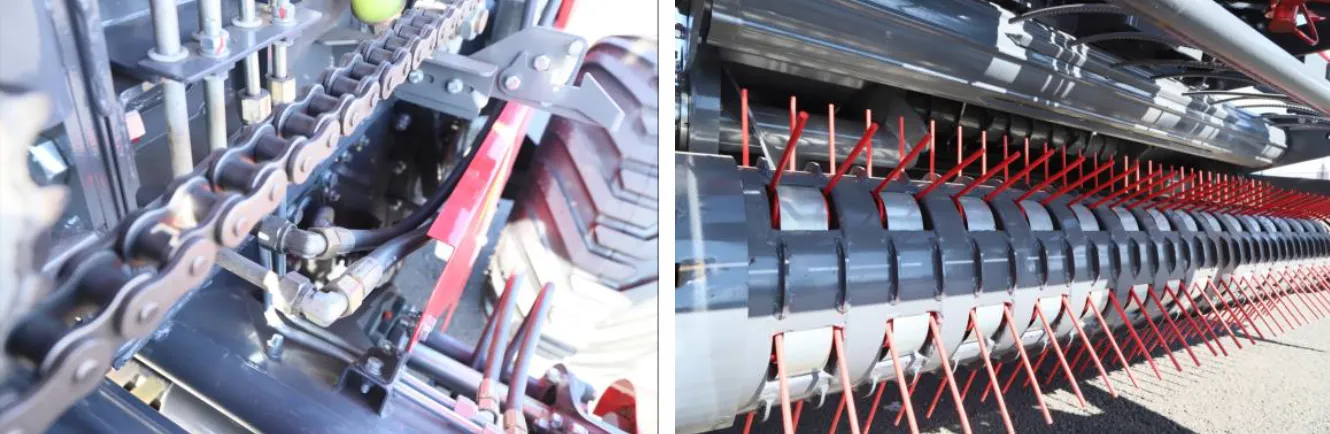

Di luar sistem pengambilan, ruang mampatan 9YG-1.0 merupakan bukti kejuruteraan tugas berat yang direka untuk ketahanan dan prestasi. Ruang ini menempatkan 16 penggelek keluli yang teguh, setiap satu dengan diameter 222mm, yang dipacu oleh sistem penghantaran rantai bertetulang. Penggelek ini direka bentuk dengan profil permukaan tertentu untuk mencengkam bahan tanaman dengan berkesan, memulakan teras putaran bale hampir serta-merta. Pembentukan teras yang pesat ini adalah penting untuk menghasilkan bal berketumpatan tinggi yang mengekalkan kualiti silaj dengan mengeluarkan oksigen.

4. Menavigasi Landskap Perundangan: Peraturan Pengimbangan di Korea Selatan dan Pasaran Global

Penggunaan jentera pertanian seperti 9YG-1.0 semakin didorong oleh peraturan alam sekitar dan undang-undang pengurusan tanah yang ketat.

Di Korea Selatan, kerajaan telah memperhebatkan tindakan kerasnya terhadap pembakaran terbuka haram hasil sampingan pertanian untuk memerangi pencemaran debu halus bermusim yang teruk. Di bawah **Akta Pengurusan Sisa** dan ordinan tempatan, petani menghadapi denda yang besar kerana membakar jerami padi atau batang jagung. Pada masa yang sama, Kementerian Pertanian, Makanan dan Hal Ehwal Luar Bandar (MAFRA) mempromosikan dasar penggunaan "Tanaman Padi Makanan", menawarkan subsidi untuk jentera yang menukar jerami menjadi makanan ternakan (IRG/Silage). 9YG-1.0 berada pada kedudukan yang sempurna untuk membantu petani mematuhi larangan ini sambil menjana wang daripada sisa tanaman mereka. Keupayaannya untuk menghasilkan bal bersih dan berketumpatan tinggi memastikan jerami memenuhi piawaian kebersihan yang diperlukan untuk makanan lembu Hanwoo, menjadikan liabiliti yang berpotensi menjadi aset yang menguntungkan. Tambahan pula, undang-undang pemuliharaan tanah tempatan menggalakkan penyingkiran jerami berlebihan untuk mencegah pengeraman perosak, satu tugas yang dikendalikan dengan cekap oleh keupayaan pengambilan bersih pembalut ini.

Melihat konteks antarabangsa yang lebih luas, Rangka kerja kawal selia yang serupa sedang membentuk pasaran untuk peralatan pengepungan. Di Eropah, khususnya negara-negara di bawah Dasar Pertanian Bersama (CAP), peraturan pematuhan silang mewajibkan pengurusan penutup tanah dan tidak menggalakkan pembakaran untuk melindungi bahan organik tanah. Walau bagaimanapun, di zon terdedah nitrat, penyingkiran jerami sering diutamakan untuk mencegah pelindian nitrogen, mewujudkan permintaan untuk pengepungan yang cekap seperti 9YG-1.0. Di Australia dan New Zealand, di mana pengurusan risiko kebakaran adalah penting, majlis tempatan menguatkuasakan pengurangan beban bahan api yang ketat ke atas hartanah luar bandar. 9YG-1.0 berfungsi sebagai alat kritikal untuk "pemuliharaan makanan ternakan", yang membolehkan pemilik tanah membersihkan rumput kering dan jerami dengan cekap sebelum musim kebakaran memuncak. Malah di pasaran baru muncul seperti Thailand dan Vietnam, kerajaan mengikuti jejak Korea dalam mengharamkan pembakaran untuk mengurangkan jerebu, memberi insentif kepada sektor penjanaan kuasa biojisim yang memerlukan rantaian bekalan jerami yang digelung yang boleh dipercayai.

5. Keserasian Jenama & Penggantian Alat Ganti

| Komponen Sistem | Konfigurasi 9YG-1.0 | Jenama Traktor Serasi (Korea Selatan) |

|---|---|---|

| Hitch Traktor | Palang Penarik Pertanian Standard | LS Mtron (Siri XP/MT7), TYM (Siri T100), Daedong (Siri Kioti PX), Kubota (Siri M) |

| Laluan Pemacu PTO | 6-Splin 540/720 RPM | Sesuai untuk aci output PTO standard pada traktor 65-100HP. |

| Bahan Pengikat | Balutan Bersih Lebar 1.0m | Sesuai dengan Tama, Novatex dan jenama jaring tempatan Korea (cth., Pungkuk). |

| Pelabuhan Hidraulik | Injap Jauh Bertindak Dua | Pengganding ISO standard yang digunakan oleh John Deere, New Holland, Massey Ferguson. |

*Penafian: Jenama lain yang dinyatakan di atas disediakan semata-mata untuk tujuan ilustrasi. Kami tidak menawarkan produk atau peralatan asli yang mempunyai jenama ini.

6. Trend Pasaran: Peralihan Ke Arah Logistik Berbilang Kecil yang Cekap

Landskap pertanian di Asia Timur sedang mengalami transformasi yang ketara ke arah automasi dan kecekapan logistik. Satu trend yang ketara ialah peralihan daripada bal besar dan sukar dikawal kepada bal berdimensi lebih kecil dan berketumpatan tinggi seperti yang dihasilkan oleh 9YG-1.0. Peralihan ini didorong oleh populasi pertanian yang semakin tua di Korea Selatan dan Jepun, di mana pengendalian bal besar memerlukan jentera yang besar dan mahal yang selalunya tidak praktikal untuk plot tanah yang berpecah-belah. Julat bal 100-200kg 9YG-1.0 sangat sepadan dengan peralihan demografi ini, membolehkan pengendalian yang lebih mudah dengan skid steer standard atau pemuat traktor yang lebih kecil. Tambahan pula, terdapat pasaran yang semakin berkembang untuk "makanan ternakan komersial", di mana jerami padi dibal bukan untuk kegunaan di ladang tetapi untuk dijual kepada pusat TMR (Jumlah Campuran Catuan) khusus. Pengkomoditian ini memerlukan bal yang seragam dari segi ketumpatan dan bentuk untuk pengangkutan trak yang cekap, satu keperluan bahawa sistem ketumpatan terkawal sensor 9YG-1.0 memenuhi dengan tepat.

7. Senario Aplikasi

1. Pengurusan Jerami Padi di Korea Selatan

Senario: Petani di kawasan pengeluar padi di Korea Selatan menggunakan 9YG-1.0 untuk mengumpul jerami padi dengan cekap selepas penuaian. Dengan sistem pemakanan Aliran Paksi yang dipatenkan, mesin penggulung ini boleh mengendalikan jerami padi basah dan melekit, meminimumkan risiko tersumbat dan memastikan operasi yang lancar dalam keadaan lembap.Aplikasi: Sesuai untuk menukar jerami padi kepada bal berketumpatan tinggi, sama ada untuk silaj atau untuk memenuhi peraturan kerajaan tempatan untuk penyingkiran jerami.

2. Penuaian Batang Jagung untuk Silaj

Senario: Di wilayah Chungcheong dan Jeolla, di mana jagung merupakan tanaman utama, 9YG-1.0 membantu petani menghasilkan bal silaj yang padat. Mekanisme Axial Flow mengendalikan tangkai jagung yang padat, menjadikan pembalut sebagai alat penting untuk menghasilkan makanan berkualiti tinggi untuk ternakan.Aplikasi: Sesuai untuk pengeluaran silaj di mana pemprosesan pantas dan bal berketumpatan tinggi diperlukan untuk memastikan penapaian dan pengawetan yang betul.

3. Alas Katil Ternakan untuk Ladang Tenusu

Senario: Ladang tenusu di Pulau Jeju menggunakan 9YG-1.0 untuk mengumpul jerami dan membuat bal untuk alas tidur. Dengan sistem pengikatan jaring automatik, bal adalah seragam, mudah diangkut dan sedia untuk digunakan segera di tempat tinggal haiwan.Aplikasi: Menyediakan bekalan alas jerami yang boleh dipercayai untuk lembu, mengurangkan pembaziran dan meningkatkan keselesaan haiwan semasa musim sejuk.

4. Pengeluaran Biotenaga

Senario: 9YG-1.0 digunakan di kawasan di mana jerami digunakan untuk penjanaan kuasa biojisim. Pengambilannya yang bersih dan bal berketumpatan tinggi memastikan bahawa sejumlah besar jerami dikumpulkan dengan cekap untuk digunakan di loji kuasa.Aplikasi: Sesuai untuk pengeluar biojisim komersial, menukarkan hasil sampingan pertanian kepada sumber tenaga boleh diperbaharui sambil mematuhi peraturan alam sekitar.

5. Penuaian Makanan Rumput untuk Lembu Pedaging di Korea Selatan

Senario: 9YG-1.0 amat berkesan dalam penternakan lembu Hanwoo, di mana para penternak memerlukan bal berketumpatan tinggi untuk memberi makan ternakan mereka. Keupayaannya untuk menghasilkan bal dalam lingkungan 100-200kg sepadan dengan keperluan industri makanan ternakan di Korea.Kegunaan: Digunakan untuk menuai dan mengumpulkan rumput dan tanaman makanan ternakan lain, menyediakan sumber makanan yang padat dan kaya dengan nutrien untuk lembu pedaging.

6. Penyingkiran Jerami di Sawah Penanaman Padi

Senario: Petani di Wilayah Gyeonggi menggunakan 9YG-1.0 untuk membersihkan lebihan jerami selepas penuaian padi. Reka bentuk pembalut yang cekap membantu memenuhi peraturan tempatan yang mewajibkan penyingkiran jerami padi bagi mencegah pengeraman perosak dan menggalakkan kesihatan tanah.Aplikasi: Memastikan pematuhan undang-undang alam sekitar dengan membuang jerami padi secara bersih dan cekap untuk pelupusan atau kegunaan selanjutnya sebagai makanan ternakan atau bahan api.

7. Pengeluaran Jerami yang Cekap untuk Petani Berskala Kecil

Senario: Petani berskala kecil di Gyeongsang dan kawasan luar bandar lain mendapat manfaat daripada reka bentuk padat 9YG-1.0, yang membolehkan mereka menghasilkan bal jerami berkualiti tinggi dengan usaha yang minimum. Reka bentuk serba boleh baler ini berfungsi dengan baik dengan rumput dan alfalfa, menyediakan penyelesaian untuk pelbagai keperluan pertanian.Aplikasi: Sesuai untuk menghasilkan bal jerami berketumpatan tinggi untuk dijual semula, digunakan dalam operasi ternakan tempatan atau untuk pengeluaran silaj.

8. Pengurusan Sisa Tanaman untuk Pematuhan Alam Sekitar

Senario: Di kawasan di mana pembakaran sisa tanaman dilarang disebabkan oleh masalah kualiti udara, seperti di beberapa bahagian Jeolla dan Gyeongbuk, 9YG-1.0 membantu petani mengumpul dan mengumpulkan jerami untuk digunakan dalam pengkomposan atau pengeluaran tenaga.Aplikasi: Alat penting bagi petani yang perlu mematuhi undang-undang alam sekitar dengan menukar sisa buangan kepada sumber berharga seperti biojisim atau bahan alas.

9. Penuaian yang Cekap di Kawasan Berbukit

Senario: Saiz padat dan sifat ringan 9YG-1.0 menjadikannya pilihan yang sangat baik untuk menuai di kawasan berbukit atau tidak rata yang terdapat di rantau Gangwon-do, di mana mesin besar lain sukar untuk dinavigasi.Aplikasi: Sesuai untuk petani yang beroperasi di kawasan yang mempunyai akses terhad kepada peralatan besar dan berat, membolehkan mereka menuai dengan cekap dalam keadaan yang mencabar.

10. Pengikatan Makanan Komersial untuk Dijual

Senario: Di kawasan di mana makanan ternakan dijual kepada pusat makanan komersial atau ladang tenusu tempatan, 9YG-1.0 membolehkan penghasilan bal seragam dan berketumpatan tinggi yang mudah diangkut dan disimpan.Aplikasi: Petani dan penyedia perkhidmatan pertanian boleh menggunakan pembalut untuk menghasilkan bal untuk dijual semula kepada pengedar makanan ternakan, memenuhi permintaan yang semakin meningkat untuk makanan ternakan berkualiti tinggi di pasaran.

8. Tentang Kami | Kilang EVER-POWER

EVER-POWER beroperasi sebagai kilang sumber utama, menggabungkan teknologi pemotongan laser canggih dan kimpalan robotik untuk memastikan integriti struktur setiap pembalut 9YG-1.0. Kami faham bahawa keadaan pertanian tidak seragam; oleh itu, kami menawarkan perkhidmatan penyesuaian yang meluas untuk memenuhi keperluan serantau tertentu.

Untuk rakan kongsi kami di Korea Selatan dan pasaran global, kami boleh menyesuaikan bahan gigi pengutip untuk keadaan tanah yang kasar,

ubah suai ketinggian palang penarik untuk model traktor tertentu,

dan sesuaikan warna casis agar sepadan dengan identiti jenama anda.

Proses kawalan kualiti kami melibatkan ujian lapangan yang ketat terhadap setiap unit sebelum penghantaran, memastikan penghantaran tanpa kecacatan. Kami menjemput pengedar dan petani berskala besar untuk merasai sendiri kecemerlangan pembuatan kami.

9. Kisah Kejayaan Pelanggan:

10. Bahagian yang boleh diganti

10.1 Kotak Gear:

Model yang serasi: Siri EP-Baler bulat (baler bulat, nisbah penghantaran 1:2, serasi dengan aci 6-spline 35mm).

Aplikasi: Menghantar kuasa PTO ke mekanisme pengedap, sesuai untuk New Holland 630 atau John Deere 535. Parameter: Tork > 500 Nm, penjimatan bahan api 20%.

Mengapa memilih kotak gear ini: Saiz boleh disesuaikan (boleh dikurangkan kepada 250-300mm), tahan terhadap bahan cemar likat (asap getah), perlindungan IP65. Aci PTO:

Model Serasi: Siri EP-PTO (spline Z6 1-3/8", panjang boleh laras 600-1200mm).

Aplikasi: Menyambungkan traktor ke pemacu utama baler, sesuai untuk jenis 9YG-1.0C. Kecekapan penghantaran tork >95%, serasi dengan bebibir SAE/EURO.

10.2 Rantai & Sproket:

Model Serasi: ANSI #50/#60 rantai, dengan EP-Sprocket (pitch 12.7-19.05mm, diameter penggelek 10-12mm).

Aplikasi: Digunakan dalam tali sawat atau mekanisme pengikat, sesuai untuk pengangkutan jerami pembalut segi empat sama/bulat. Lebar 25-40mm, bahan keluli tahan haus.

10.3 Gandingan:

Model Serasi: Gandingan EP siri 200 (pemadanan tork 500-1000 Nm).Aplikasi: Menyambungkan kotak gear kepada penggelek pengedap, meredam getaran.

10.4 Silinder Hidraulik:

Silinder Hidraulik: Siri EP-HC (lubang 50-100mm, lejang 300-600mm), sesuai untuk mengangkat bale.Galas dan Pengedap: Galas 6208-2RS, jangka hayat L10 >10000 jam, pengedap kalis habuk.Jadual Keserasian: Boleh ditukar ganti sepenuhnya dengan Comer 250T (pemadanan tork, hanya 35% daripada harga); bebibir sepadan dengan Corak PTO 4-Bolt Amerika Utara.

11. Soalan Lazim (FAQ)

S1. Bagaimanakah mekanisme penyuapan 9YG-1.0 mencegah penyumbatan semasa mengikat jerami padi basah di Korea?

A1. 9YG-1.0 menggunakan sistem pemakanan separa paksa "Axial Flow" yang dipatenkan digabungkan dengan pikap tanpa kam. Tidak seperti trek tradisional yang boleh tersekat dengan jerami basah dan melekit, reka bentuk pemakanan langsung ini memaksa bahan masuk ke dalam ruang dengan lancar, sekali gus mengurangkan kebarangkalian penyumbatan dengan ketara walaupun dalam keadaan lembap yang biasa berlaku semasa musim menuai Korea.

S2. Adakah pembalut bulat 9YG-1.0 serasi dengan traktor LS Mtron 70HP saya?

A2. Ya, sudah tentu. 9YG-1.0 dioptimumkan untuk julat kuasa 48-80 kW (lebih kurang 65-108 HP). Traktor LS Mtron 70HP anda berada dalam julat ini dengan sempurna, memastikan operasi yang cekap tanpa membebankan enjin atau sistem PTO traktor.

S3. Berapakah berat purata bal yang dihasilkan oleh mesin ini, dan adakah ia mudah diangkut?

A3. Berat bale biasanya antara 100kg hingga 200kg (200-400 jin), bergantung pada tetapan kelembapan dan ketumpatan tanaman. Saiz ini sesuai untuk logistik berskala kecil hingga sederhana, membolehkan pemuatan mudah ke atas trak 1 tan standard Korea (Porter/Bongo) tanpa memerlukan kren perindustrian berat.

S4. Bolehkah mesin pembalut ini mengendalikan batang jagung untuk silaj serta jerami padi?

A4. Ya, 9YG-1.0 ialah mesin yang serba boleh. Ruang 16-roller tugas berat dan pikap yang teguh direka bentuk untuk mengendalikan bahan-bahan yang keras dan berserat seperti batang jagung sama berkesannya dengan jerami padi, menjadikannya penyelesaian dwiguna untuk pelbagai operasi pertanian.

S5. Di manakah saya boleh membeli alat ganti seperti tine pikap atau jaring pengikat di Korea Selatan?

A5. EVER-POWER menyokong rangkaian alat ganti global. Kami boleh menghantar alat ganti seperti gigi spring dan penggelek terus ke lokasi anda di Korea Selatan melalui kurier ekspres. Selain itu, sistem pengikatan jaring menggunakan gulungan standard selebar 1.0m, yang serasi dengan jenama biasa yang terdapat di dalam negara.

S6. Adakah sistem pengikatan jaring automatik memerlukan campur tangan manual semasa operasi?

A6. Tidak, sistem ini automatik sepenuhnya. Sebaik sahaja sensor mengesan bahawa bal telah mencapai ketumpatan sasaran, mekanisme pengikatan jaring akan diaktifkan secara automatik. Operator hanya perlu mengeluarkan bal secara hidraulik, membolehkan penuaian tanpa henti yang berterusan dan cekap.

S7. Apakah jangkaan masa penghantaran untuk pesanan kontena ke pelabuhan Busan atau Incheon?

A7. Secara amnya, masa pengeluaran kami adalah 15-20 hari untuk pesanan standard. Penghantaran dari kilang kami ke pelabuhan utama Korea seperti Busan atau Incheon adalah sangat pantas, biasanya mengambil masa kurang daripada seminggu sebaik sahaja kapal berlepas, memastikan anda mendapat peralatan anda sebelum musim menuai.

S8. Bagaimanakah sensor kawalan ketumpatan meningkatkan kualiti bal silaj?

A8. Kawalan sensor memastikan setiap bale dimampatkan kepada ketumpatan yang seragam dan tinggi. Ketumpatan yang tinggi adalah penting untuk silaj kerana ia meminimumkan poket udara di dalam bale, menggalakkan penapaian anaerobik yang lebih baik dan mencegah kerosakan, yang secara langsung diterjemahkan kepada nilai pemakanan yang lebih tinggi untuk ternakan anda.

S9. Bolehkah saya mendapatkan warna tersuai untuk baler agar sepadan dengan armada jentera saya yang sedia ada?

A9. Ya, sebagai pengeluar sumber, kami menawarkan pilihan penyesuaian termasuk warna. Jika anda mempunyai keperluan warna armada tertentu (cth., sepadan dengan warna hijau John Deere atau oren Kubota), kami boleh mengecat casis mengikut spesifikasi anda untuk penampilan yang seragam. Sila hubungi kami untuk sebut harga khusus mengenai penyesuaian.

S10. Apakah perbezaan antara model 9YG-1.0 dan 9YG-2.24D yang lebih besar?

A10. 9YG-1.0 ialah unit yang lebih padat dengan pikap 1.9m dan ruang 1000mm, dioptimumkan untuk traktor yang lebih kecil (65-100HP) dan medan yang lebih sempit. 9YG-2.24D ialah mesin yang lebih besar dengan pikap 2.24m, direka bentuk untuk traktor kuasa kuda yang lebih tinggi dan operasi medan terbuka berskala besar. 9YG-1.0 sering digemari kerana kebolehgerakannya di sawah padi berbukit atau bersegmen.

Terokai Penyelesaian Pertanian Berkaitan

Konsep yang Lebih Luas: Penuaian Makanan Rumput, Pengeluaran Silaj, Pertanian Lestari, Tenaga Biojisim.

Produk Berkaitan: Aci PTO untuk Baler, Kotak Gear Pertanian, Mesin Pembungkus Silaj, Penyapu Jerami.

Industri Sasaran: Penternakan Daging Lembu & Tenusu (Hanwoo), Penanaman Padi, Penanaman Jagung/Jagung, Tenaga Boleh Diperbaharui.

*Penafian: Jenama lain yang dinyatakan di atas disediakan semata-mata untuk tujuan ilustrasi. Kami tidak menawarkan produk atau peralatan asli yang mempunyai jenama ini.

Bersedia untuk Menaik Taraf Hasil Tuai Anda?

Hubungi EVER-POWER hari ini untuk harga eksklusif, spesifikasi dan butiran penghantaran ke Korea Selatan.

Emel: [email protected]

Editor: PXY