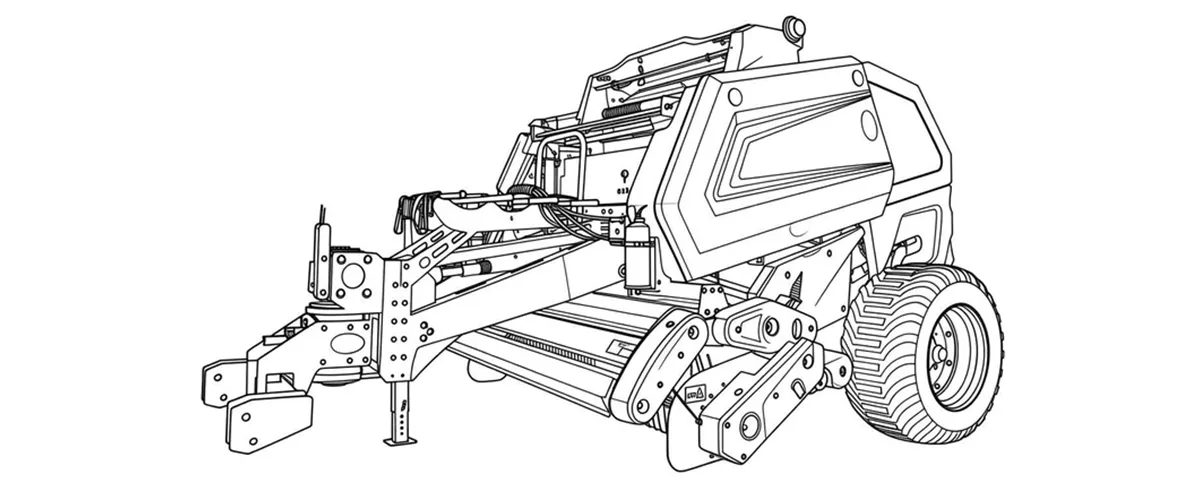

EP-9YG-2.24D-Prasa zwijająca-S9000 Super

The defining innovation of the S9000 Transcend is its revolutionary Autonomous Double Cross Universal Joint Drive Shaft system. Traditional balers struggle with power transmission during tight turns, often forcing operators to disengage the PTO or take wide, inefficient loops. The Transcend model features a dual-gearbox design capable of articulating 90 degrees left or right without interrupting power flow. This “Zero-Downtime Turn” capability is a game-changer for Korean contractors working in confined fields, allowing for continuous harvesting even at headlands. This mechanical agility, combined with a rigid connection stability system, ensures that the drive shaft remains protected against torque spikes, significantly reducing the risk of catastrophic failure during the peak harvest window.

Beyond its structural superiority, the S9000 Transcend integrates an advanced “Axial Flow” feeding system designed to handle the abrasive, silica-rich nature of Asian rice straw. While European balers often clog with long, wet straw, the Transcend’s Dial Tine Roller and Drum combination forcefully feeds crop into the 18-roller chamber. This semi-forced feeding mechanism ensures a consistent material flow, preventing blockages that plague lesser machines. By harmonizing heavy-duty compression with agile maneuverability, the S9000 Transcend allows professional operators to maximize their daily output, securing more government subsidies through superior bale quality and operational efficiency.

1. Technical Specifications: 9YG-2.24D (S9000 Super)

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Super) |

| 2 | Hitch Type | / | Trailed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Spring Type |

| 5 | Feeding Mechanism Structure | / | Feeding Rotor + Roller Type |

| 6 | Compression Chamber Structure | / | Roller Chamber |

| 7 | Compression Chamber Width | mm | 1400 |

| 8 | Compression Chamber Diameter | mm | Φ1200 |

| 9 | Number of Roller Working Components | pcs | 18 (Rollers) |

| 10 | Roller Diameter | mm | Φ222 |

| 11 | Baling Method | / | Net Wrapping |

| 12 | Required Power | kW | 55-100 |

| 13 | Structural Weight | kg | 4570 |

| 14 | PTO Output Shaft Speed | r/min | 720 |

| 15 | Dimensions (L × W × H) | mm | 4600 × 3010 × 2370 (working condition) |

| 16 | Forage Density Control | / | Sensor-Controlled |

| 17 | Bale Size (Length × Width × Height) | mm | Φ1300 × 1400 |

| 18 | Bale Density | kg/m³ | 100–200 |

| 19 | Productivity | bale/h | 40–100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Operating Speed | km/h | 5–35 |

| 22 | Net Wrap Specification | m | 2000×1.4 / roll |

2. Five Key Facts

Model and Application:

The S9000 Super is a high-performance round baler designed for heavy-duty use, ideal for various agricultural applications such as rice paddy harvesting, silage production, and biomass management in fields across different countries.

Compression and Baling System:

It features an advanced 18-roller compression system that efficiently handles tough materials like rice straw, corn stalks, sugarcane straw, and more. The machine ensures high bale density, making it highly effective for feed and silage production.

Power and Performance:

The baler requires a tractor with a power range of 55-100 kW (75-135 HP). It operates at a PTO output shaft speed of 720 rpm, allowing efficient baling with a productivity rate of 40-100 bales per hour.

Global Compatibility:

The S9000 Super is compatible with major tractor brands, including LS Mtron XP Series and TYM/Kukje models. Additionally, it supports standard net wrap systems like Tama and Novatex, making it versatile for different operational setups.

Regulatory Compliance:

The baler is built to comply with strict local regulations, such as South Korea’s Agricultural Machinery Promotion Act, ensuring it meets environmental standards and soil conservation guidelines, especially in regions with sensitive or uneven terrain like paddy fields.

3. Engineering Core: Working Principle & Material Metallurgy

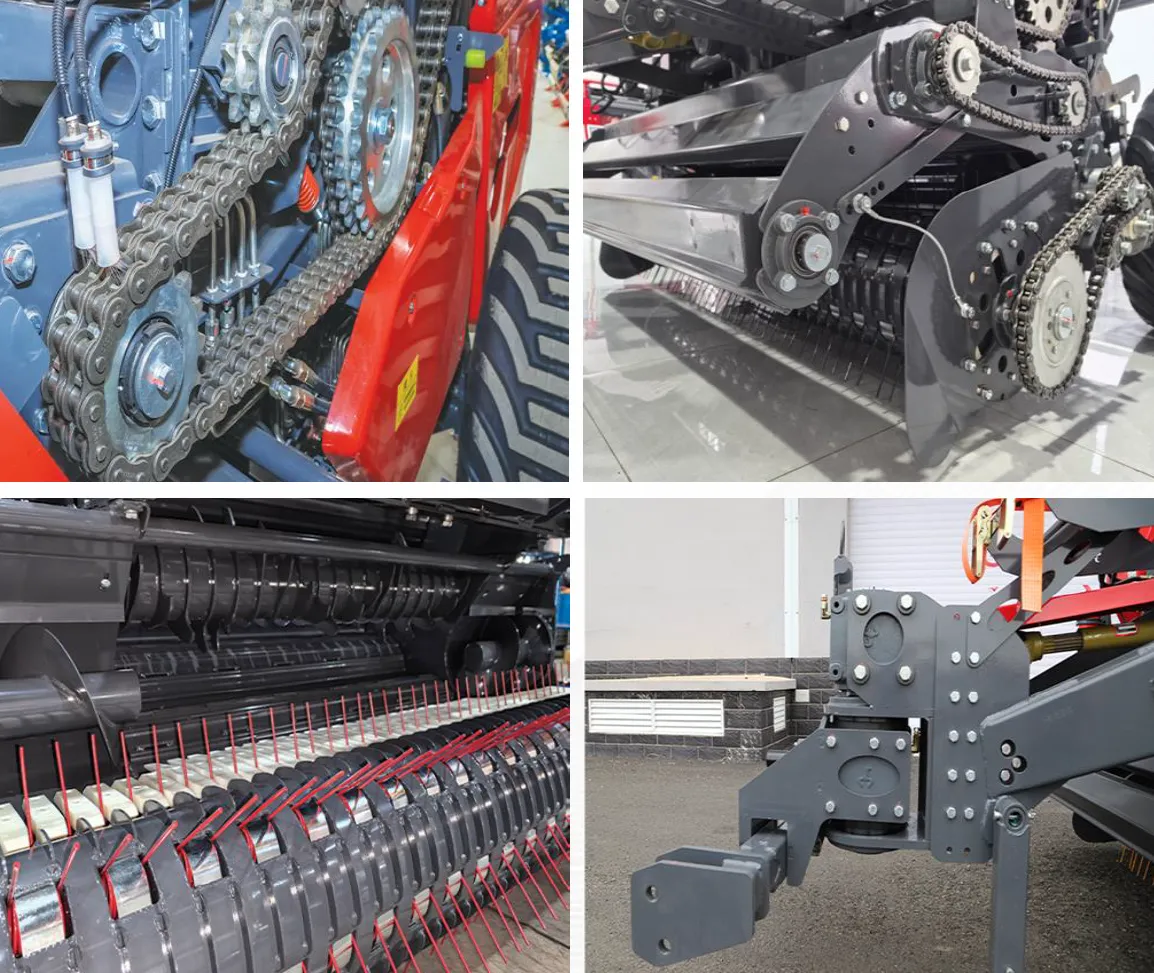

The S9000 Super operates on a high-compression roller principle. As the 2240mm pickup lifts the windrow, the crop is pre-compressed by the feed rotor before entering the main chamber. The 18 rollers, manufactured from Q345B high-strength alloy steel, rotate to form the bale core. The "Transcend" distinction lies in its drivetrain: power is transmitted through a heavy-duty gearbox to the rollers via 20A reinforced chains, which offer 30% higher tensile strength than standard 16A chains found in competitor models.

| Component | Material / Spec | Function & Benefit |

|---|---|---|

| Compression Rollers | Φ222mm, 4mm Wall Thickness Heat-Treated Alloy Steel | Resists deformation under high pressure; "Ribbed" profile ensures positive bale rotation even with wet, slippery straw. |

| Drive Chains | 20A (1-inch pitch) Reinforced High-Carbon Steel | Handles the torque spikes of the 4570kg machine; extended fatigue life reduces mid-season chain breaks. |

| Pickup Tines | Spring Steel (65Mn) Shot Peened | Provides flexibility to bounce back after hitting stones; wear-resistant against abrasive soil contact. |

| Chassis Frame | Laser-Cut Structural Steel Robotically Welded | Supports the 4.5-ton dynamic load; ensures alignment of bearings and shafts on uneven terrain. |

4. Application Scenarios

4.1. South Korea – Rice Paddy Harvesting in Jeollanam-do

In the terraced paddies of Jeollanam-do, the S9000 Transcend excels by handling the dense and wet rice straw efficiently. Its high-density baling system ensures that farmers meet the strict silage standards set by the Ministry of Agriculture. The baler's flotation tires also prevent soil compaction, making it ideal for wet, uneven terrain.

4.2. Japan – Silage Production for Dairy Farms in Hokkaido

Hokkaido, known for its dairy farming, benefits from the S9000 Transcend's ability to produce dense, high-quality silage. The baler handles high-moisture crops like ryegrass with ease, ensuring that the silage meets the strict fermentation standards necessary for dairy cattle feed, especially during harsh winters.

4.3. USA – Corn Stalk Baling in the Midwest

In the Midwest, where corn stalks are abundant after harvest, the S9000 Transcend's 18-roller compression system proves invaluable. The heavy-duty rollers efficiently compress the fibrous corn stalks into compact, transportable bales, improving the efficiency of feed production for cattle ranches.

4.4. Brazil – Sugarcane Straw Management

In Brazil’s vast sugarcane fields, the S9000 Transcend is a vital tool for managing sugarcane straw. With its wide pickup width and high productivity, it clears the field quickly, turning sugarcane waste into valuable biomass for energy production, contributing to the country's renewable energy initiatives.

4.5. Australia – Hay Baling for Livestock in Queensland

On Australia’s dryland farms, the S9000 Transcend is used for hay baling in expansive fields. The baler’s ability to form high-density bales ensures that hay can be stored and transported efficiently, helping farmers manage their feed supplies through the dry season.

4.6. South Africa – Forage Baling in Western Cape

In South Africa, particularly in the Western Cape, the S9000 Transcend provides farmers with a reliable solution for forage and silage baling. The machine's high-density system is perfect for creating high-quality feed for livestock, which is essential during the dry months when fresh forage is scarce.

4.7. France – Silage Production for Cattle Feed in Brittany

In the cattle-dense region of Brittany, France, the S9000 Transcend is used for silage production. The machine’s advanced technology ensures that bales are tightly packed, providing anaerobic conditions that preserve the silage for long-term storage, meeting the demands of dairy farmers in the region.

4.8. Russia – Wheat Straw Baling for Winter Preparation in Krasnodar

The S9000 Transcend is well-suited for the Russian region of Krasnodar, where winter wheat straw must be efficiently baled and stored. The baler handles tough, silica-rich straw with its robust roller system, making it ideal for preparing straw for bedding or feed during the harsh Russian winter.

4.9. New Zealand – Pasture Management for Dairy Farms

New Zealand’s dairy farmers rely on the S9000 Transcend for managing pasture grass. The baler's axial flow rotor efficiently handles wet grass, ensuring that bales are densely packed and ready for long-term storage, which is critical for maintaining dairy cow nutrition through the winter months.

4.10. China – Rice Straw Collection for Bioenergy Production

In China, the S9000 Transcend plays a crucial role in rice straw management, converting agricultural waste into valuable biomass. The machine’s high-density baling system is well-suited for transforming rice straw into compact bales, which are then used for bioenergy production, helping China meet its renewable energy goals.

5. Global Standards & South Korean Legal Compliance

Operating heavy machinery requires strict adherence to local laws. The S9000 Super is designed to meet the rigorous standards of the Korean Agricultural Machinery Promotion Act and environmental regulations.

- 1. Direct Payment for Public-Interest (Gong-ik Jikbul-geum):

Korean farmers are eligible for subsidies when utilizing straw for silage instead of burning it. The S9000 Transcend's ability to produce bales with densities exceeding 150kg/m³ ensures compliance with "Grade A" silage standards, maximizing subsidy payouts for users. - 2. Soil Conservation & Compaction (Rural Development Administration Guidelines):

Despite its 4570kg mass, the S9000 employs wide 500/50-17 flotation tires. This design adheres to RDA recommendations for minimizing paddy pan compaction, preserving soil structure for future rice planting cycles. - 3. Road Safety Regulations:

The machine width (3010mm) exceeds standard road limits in some provinces. We provide standard reflective safety kits and slow-moving vehicle (SMV) triangles to comply with Korean Road Traffic Act requirements for agricultural machinery transport.

6. Brand & Component Compatibility Matrix

The S9000 Super is engineered to be a superior alternative to several market incumbents and works seamlessly with major tractor brands.

| Category | Brand / Model | S9000 Super Compatibility / Status |

|---|---|---|

| Tractor (Korea) | LS Mtron XP Series (XP85/XP100) | ✔ Perfectly Compatible (Hydraulics & PTO match) |

| Tractor (Korea) | TYM / Kukje T1003 / T1104 | ✔ Compatible (Requires 6-spline PTO adapter) |

| Net Wrap | Tama / Novatex (1.23m / 1.25m) | ✔ Universal System (Adjustable tensioner included) |

| Replacement For | McHale F5500 / Kuhn FB Series | Cost-Effective Alternative (Similar density, lower TCO) |

7. Market Trends: The Shift to Heavy-Duty Automation

The South Korean agricultural sector is currently undergoing a "Structural Consolidation" phase. As the farming population ages, land is being consolidated into larger cooperative plots managed by professional contractors (Young-nong-johap). This shift drives a demand for machinery that is not just functional, but industrial-grade.

1. Demand for High Density: With the rising cost of imported feed, the value of domestic rice straw silage has skyrocketed. Farmers demand bales that are "rock hard" to prevent air pockets and mold. The S9000 Transcend’s 18-roller fixed chamber is specifically trending over belt balers, which often fail to achieve core density in wet rice straw.

2. Maneuverability is Key: Unlike the vast fields of the USA or Australia, Korean paddies are segmented. The trend is moving towards equipment like the S9000 Transcend that features "articulated towing" capabilities, allowing for continuous operation in zig-zag paddy patterns without damaging the driveline.

8. EVER-POWER Manufacturing: Precision & Customization

Located in the Hulunbuir Economic Zone, our 32,000 sqm facility is a hub of agricultural innovation. We don't just assemble; we manufacture. Utilizing CNC laser cutting and electrostatic powder coating, we ensure every S9000 Transcend can withstand the humid, corrosive environments typical of coastal rice farming.

OEM & Customization Services

- ✔ Color Matching: We can paint the S9000 to match your dealership's brand identity (e.g., LS Blue, TYM Red).

- ✔ Hitch Adaptation: Custom drawbars available for specific tractor hitches or 2-point linkages.

- ✔ Decal & Branding: Full private labeling services for regional distributors.

9. Customer Success Story

"As a dairy farmer in Hokkaido, I rely on silage to feed my cows during the winter. The S9000 Super delivers excellent bale density, and it handles high-moisture ryegrass without any issues. I’m impressed with the net wrapping system that keeps everything secure and prevents spoilage."

---Taro from Hokkaido, Japan

"We use the S9000 Super to bale corn stalks, and I’m very impressed with how it performs. The 18-roller compression system ensures the bales are dense, and the drivetrain is robust enough to handle the tough material. It’s a big improvement over our old balers!"

---Robert from Kansas, USA

"I farm sugarcane, and the S9000 Super has been fantastic for managing the straw. The pickup width and high-speed operation help us clear fields quickly. The bales are easy to transport, and we’re able to turn all that straw into valuable biomass for energy production."

---Carlos from São Paulo, Brazil

"On our dryland farm, the S9000 Super has made hay baling so much easier. The ability to form tightly packed bales ensures we can store and transport more efficiently. The bale density is perfect, and it’s so much faster than the other balers we’ve used."

---Peter from Queensland, Australia

"Winter wheat straw is tough, but the S9000 Super handles it effortlessly. The reinforced steel rollers compress the straw into perfectly shaped bales, and the machine operates smoothly in our challenging fields. It’s definitely built for durability!"

---Mikhail from Krasnodar, Russia

10. Replaceable parts

10.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection.

10.2 PTO SHAFT:

Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

10.3 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

10.4 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

10.5 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

11. Other products in the same series (2.24D)

12. FAQ:

Q1. How does the S9000 Super's 4570kg weight impact stability on wet Korean rice paddies?

A1. While heavier than the Classic model, the S9000 Transcend utilizes extra-wide flotation tires that distribute the 4570kg mass effectively. This ensures superior traction and stability, preventing sinking even in post-rain harvest conditions typical of the Korean autumn.

Q2. What is the main advantage of the "Autonomous Double Cross Universal Joint" for my tractor?

A2. This system is a lifesaver for drivelines. It allows the baler to turn up to 90 degrees relative to the tractor while the PTO is still running at full torque. You don't need to stop or disengage power at headlands, which is crucial for efficiency in small, segmented fields.

Q3. Can this baler handle the high-moisture Italian Ryegrass (IRG) crops grown in the south?

A3. Absolutely. The "Transcend" edition features a specialized "Axial Flow" feeding rotor with aggressive tine profiles. This design actively grabs wet, heavy IRG and forces it into the chamber, eliminating the "slippage" issues seen in passive feed systems.

Q4. Where can I find spare parts like pickup tines or 20A chains in South Korea?

A4. EVER-POWER has established a robust parts network. We stock critical consumables like 20A heavy-duty chains, bearings, and tines in our partner warehouses in Korea, ensuring overnight delivery to minimize downtime during the harvest rush.

Q5. Is the bale size compatible with standard Korean silage wrappers like McHale or domestic brands?

A5. Yes, the bale chamber produces a standard Φ1250mm x 1230mm (approx. 4x4 ft) bale. This dimension is the industry standard in Korea and fits perfectly on all major wrapper turntables, ensuring seamless integration into your existing workflow.

Q6. How does the heavy-duty roller system compare to belt balers for rice straw?

A6. Rice straw is abrasive and slippery. Belt balers often struggle to start the core. Our 18 steel rollers with ribbed profiles provide positive grip, ensuring immediate core formation and higher density, which is essential for maximizing the value of the straw.

Q7. What is the minimum horsepower requirement for safe operation on slopes?

A7. The specs list 55kW (75HP) as a minimum, but for the Transcend model on hilly terrain (like in Gangwon-do), we strongly recommend a 95HP-110HP tractor. The extra power ensures safe braking and stability when towing the 4.5-ton unit downhill.

Q8. Does the machine come with an automatic lubrication system for the chains?

A8. Yes, the S9000 Transcend is equipped with a centralized automatic oiling system. It lubricates the main drive chains every time the tailgate opens, significantly extending chain life and reducing the daily maintenance burden on the operator.

Q9. How fast can I tow the S9000 Super on public roads between fields?

A9. While the unit is stable, we recommend a maximum transport speed of 25-30 km/h on paved roads to protect the tires and wheel bearings. Always ensure your safety lights and SMV triangle are visible to other traffic.

Q10. Can I get a quote including shipping to Pyeongtaek or Busan port?

A10. Certainly. We offer CIF pricing to all major Korean ports including Incheon, Pyeongtaek, and Busan. Click the "Inquire Now" button below to get a detailed quote tailored to your location and quantity requirements.

Editor: PXY