Description

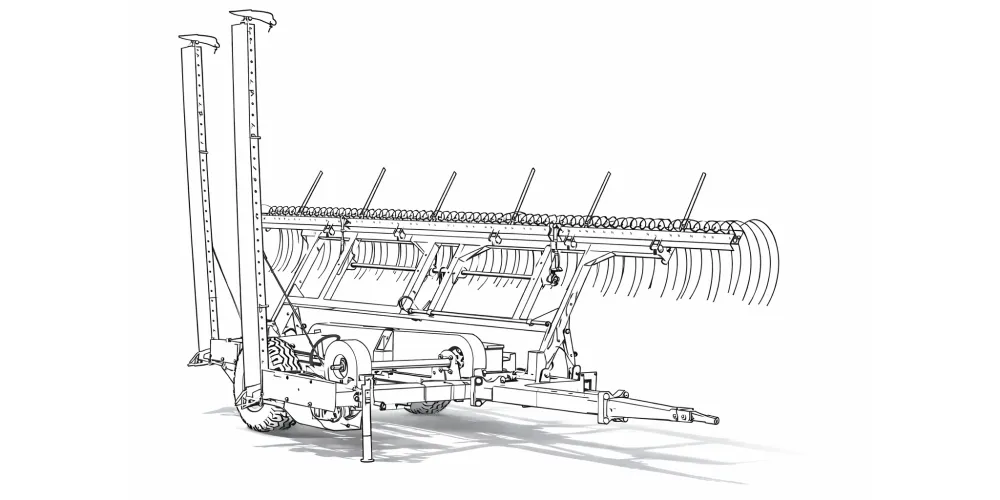

1. Technical Specifications: EP-9GL-5.0/5.6 Integrated Harvester

| Item No. / Parameter | Unit | Specification | |

|---|---|---|---|

| 1 | Model Name | EP-9GL-5.0/5.6 Towed Mower | |

| 2 | Hitch Method | Towed | |

| 3 | Cutter Structure Type | Reciprocating | |

| 4 | Cutting Width | m | 5 |

| 6 | Machine Width | m | 5.6 |

| 7 | Working Speed Range | km/h | 6~7 |

| 8 | Productivity | hm²/h | Cut: 2.4-2.8, Tow: 3.0-3.6 |

| 9 | Average Cutting Height | mm | 60-70 |

| 10 | Matched Power | kw | 30~60 |

| 11 | PTO Shaft Speed | r/min | 540 |

| 12 | Machine Weight | kg | 1100 |

| 13 | Number of Connectors | pieces | 78 |

| 14 | Connection Distance | mm | 71 |

| 15 | Machine Dimensions | mm | Length × Width × Height |

| 16 | Transport Mode | 3860 × 5600 × 3000 | |

| 17 | Working Mode | 3860 × 7600 × 850 | |

| 18 | Number of Moving Blades | pieces | 68 |

2. Revolutionizing Pasture Management: The 9GL-5.0/5.6 Tractor-Mowered Lawn Mower

In the high-stakes world of modern agriculture, specifically within the forage production sectors of South Korea and East Asia, efficiency is not merely a metric—it is the difference between profit and loss. The 9GL-5.0/5.6 Tractor-Mowered Lawn Mower (also technically identified as a Towed Cut-Rake Integrated Machine) represents a paradigm shift in harvesting technology. Unlike standard single-function implements, this machine ingeniously combines the cutting and raking processes into a single pass. Designed to be towed by mid-to-high horsepower tractors (40-80 HP), it addresses the critical labor shortages currently facing provinces like Gyeongsangbuk-do and Jeollanam-do. While many users search for the best tractor powered lawn mower for residential use, the 9GL series defines the industrial standard for large-scale pasture management. By integrating a reciprocating cutter bar with a heavy-duty raking mechanism, this machine ensures that natural and planted pastures are harvested and windrowed simultaneously. This reduces field traffic by 50%, significantly minimizing soil compaction—a vital factor for maintaining the long-term health of perennial ryegrass and alfalfa fields common in the region.

The engineering philosophy behind the 9GL-5.0/5.6 focuses on adaptability and rugged durability. The machine features a substantial cutting width of 5.0 meters and a raking width of 5.6 meters, allowing for massive areal coverage of up to 3.6 hectares per hour. This is not a toy like a residential riding lawn mower clearance item; it is a heavy agricultural asset. The hydraulic control system allows the operator to lift and lower the cutting and raking units independently from the tractor cab, ensuring seamless transitions between working and transport modes. For Korean farmers dealing with tight harvest windows due to the monsoon season (Jangma), the ability to cut and rake in one go means the crop begins the drying process immediately, reducing the risk of mold and spoilage. Whether you are managing a dairy farm in Icheon or a beef cattle operation in Hoengseong, the 9GL-5.0/5.6 delivers the reliability required to secure high-quality feed stocks for the winter months.

2. Operational Mechanics, Material Science, and Application Scenarios

The working principle of the 9GL-5.0/5.6 is a symphony of mechanical synchronization. Power is derived from the tractor’s rear PTO (540 r/min), which drives the reciprocating cutter bar. This cutter utilizes high-carbon alloy steel knife sections that shear the grass stems cleanly, similar to a scissor action. This method is agronomically superior to rotary impact cutting for certain legumes, as it minimizes leaf shatter and preserves protein content. Simultaneously, the rear-mounted raking system, comprised of 78 flexible steel tines arranged on finger wheels, gently gathers the cut crop. As the machine moves forward, the angle of the finger wheels rolls the forage into a neat, fluffy windrow to the side. This structure allows air to permeate the swath, accelerating the curing process. The chassis is constructed from reinforced Q345 structural steel, ensuring it can withstand the torsional stresses of uneven terrain without warping. The tires are agricultural flotation tires, designed to carry the 1100kg weight without creating deep ruts in soft soil conditions.

Regarding application scenarios, this tractor-powered lawn mower for sale is specifically engineered for “Flat Pastures and Gentle Slopes.” It excels in harvesting tall forage crops such as Timothy grass, Orchard grass, and Alfalfa. In the context of South Korean agriculture, it is particularly effective for harvesting Italian Ryegrass (IRG) on reclaimed land where the terrain is expansive and flat. However, operators must note the limitations: this machine is not a forestry mulcher. It is strictly prohibited for use in wetlands, bogs, or rocky wastelands where “Tower Heads” (large protruding rocks) or tree stumps are present. Striking such obstacles can damage the reciprocating knife guards and bent the raking tines. While it functions differently than a John Deere tractor powered lawn mower designed for golf courses, its utility in the agricultural sector is unmatched. It provides a clean cut with a stubble height of 60-70mm, which is optimal for rapid crop regrowth and protecting the soil surface from erosion.

3. Global Safety Standards and Korean Agricultural Regulations

Navigating the complex landscape of agricultural machinery regulations is essential for compliance and safety. The 9GL-5.0/5.6 is manufactured in adherence to the Chinese National Standard GB/T 10940-2008 (Reciprocating Mowers), which aligns with major international ISO safety protocols regarding moving parts protection. For our clients in South Korea, this machine meets the rigorous safety inspection criteria established by the Korea Agricultural Technology Promotion Agency (KOAT). Key compliance features include fully shielded PTO shafts to prevent entanglement accidents—a mandatory requirement under Korea’s Agricultural Mechanization Promotion Act. Furthermore, the hydraulic systems are equipped with check valves to prevent sudden drops during transport, adhering to road safety regulations when moving equipment between fields.

Globally, there is an increasing focus on environmental sustainability in agriculture. While this implement is not self-propelled and thus does not have an engine, its design contributes to carbon reduction. By combining two passes (cutting and raking) into one, it effectively halves the diesel consumption of the towing tractor per hectare harvested. This aligns with the European Union’s “Farm to Fork” strategy and South Korea’s “Green New Deal” initiatives aimed at reducing the carbon footprint of farming operations.

4. Tractor Compatibility & Interface Comparison

| Feature | Ever-Power 9GL-5.0/5.6 Req. | LS Tractor (e.g., MT5 Series) | TYM Tractor (e.g., T60 Series) | John Deere (5E Series) |

|---|---|---|---|---|

| Horsepower | 40 – 80 HP | Compatible (50-70HP models) | Compatible (55-75HP models) | Compatible (50-75HP models) |

| PTO Spline | Standard 6-Spline (540 RPM) | Standard | Standard | Standard |

| Hydraulics | 1 or 2 Rear Remote Valves | Standard on Utility models | Standard on Utility models | Standard |

| Hitch Type | Drawbar (Pin Type) | Standard Drawbar | Standard Drawbar | Standard Drawbar |

5. Customer Success Story:

Customer 1: Carlos, Agricultural Manager – Colombia

“We’ve been using the 9GL-5.0 for two seasons now, and it’s performed beautifully in our tropical conditions. The raking system really helps with fast drying, and the hydraulic lift makes field transitions a breeze. It’s also heavy-duty enough to handle our rough terrain in Meta. We’re getting our hay done much quicker, and the build quality is top-notch!”

Customer 2: Jinwoo, Ranch Owner – South Korea

“Running a dairy farm in Gangwon-do, I needed something efficient and easy to use, and the 9GL-5.0 was the perfect fit. It works great in wet conditions, doesn’t clog like other mowers, and the low power requirement means I’m not spending much on fuel. The one-pass cutting and raking system saves me time and money, making it a solid investment for any farm.”

Customer 3: David, Contractor – USA

“I’ve been using the 9GL-5.0 in commercial hay operations across the Midwest, and it’s quickly become my go-to machine. It’s incredibly reliable, even on long days, and the 5-meter width really boosts productivity. The heavy-duty gearbox and the friction clutch are built to last—no downtime, even under demanding conditions. I can cover large fields in no time!”

Customer 4: Miguel, Livestock Farm Owner – Spain

“The 9GL-5.0 is perfect for our large pasture areas. It handles legume crops like alfalfa very well, preserving the leaves while cutting cleanly. It’s not too hard on my tractor, and the ability to use it on gentle slopes adds versatility. I’ve seen a noticeable improvement in efficiency since switching to this mower, and I’m very happy with its performance.”

6. Market Trends: The Shift to Integrated Implements

The global agricultural machinery market is witnessing a distinct pivot towards “Process Integration.” Farmers are no longer asking “what is the best tractor lawn mower” for simple cutting; they are asking for multi-functional solutions. Data from 2024 indicates a 25% rise in the demand for combination implements in East Asia. The drivers are clear: aging farming populations and rising diesel costs. In South Korea, where the rural labor force is shrinking, one operator doing the work of two is essential. Furthermore, the trend is moving away from complex, high-maintenance self-propelled units towards robust, tractor-towed implements that are easier to repair and maintain. The 9GL-5.0/5.6 aligns perfectly with this trend, offering high productivity with low maintenance complexity (fewer gearboxes, mechanical drives) compared to complex garden tractors with attachments.

7. Replaceable parts

7.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection.7.2 PTO SHAFT:

Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

7.3 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

7.4 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

7.5 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

Frequently Asked Questions (FAQ)

Q1. How much does the 9GL-5.6 tractor powered lawn mower cost including shipping to Incheon, Korea?

A1. The price varies based on steel costs and current exchange rates. However, we offer very competitive CIF Incheon pricing.

Q2. Is there a difference between a lawn mower and a lawn tractor when using this implement?

A2. Yes, significantly. A “lawn tractor” usually refers to a small garden vehicle. This 9GL-5.6 implement requires a full-sized agricultural utility tractor (40HP+) with a rear PTO and hydraulic remotes, not a residential riding lawn mower.

Q3. Can this machine process heavy wet rice straw after the paddy harvest?

A3. Yes, the 9GL series is designed with heavy-duty rake tines that can handle the weight of wet rice straw (straw) effectively, making it ideal for the post-harvest season in Korea.

Q4. What is the best tractor lawn mower attachment for 100 hectares of rye grass?

A4. For large areas like 100 hectares, a combination machine like the 9GL-5.6 is superior to a standard mower. It cuts and windrows simultaneously, saving you hundreds of hours of labor compared to using separate machines.

Q5. Do you supply spare parts like reciprocating blades and rake tines to South Korea?

A5. Absolutely. We provide a comprehensive spare parts kit with every machine. Additionally, we can ship consumable parts like knife sections and tines via express courier to Busan or Seoul within 3-5 days.

Q6. Why did people stop using push mowers for commercial forage harvesting?

A6. Why did people stop using push mowers? Simply put: scale and efficiency. You cannot harvest 50 acres of feed with a push mower. Tractor-powered implements like the 9GL provide the speed and power necessary for commercial livestock feed production.

Q7. Will this mower connect to my older John Deere 5055E tractor?

A7. Yes, the John Deere 5055E has sufficient horsepower (approx. 55HP) and a standard Category II hitch and 540 PTO, making it a perfect match for the 9GL-5.0/5.6.

Q8. How does the 9GL compare to a stiga ride on mower mulcher for field work?

A8. A stiga ride on mower mulcher is for maintaining short grass on lawns. The 9GL is for harvesting long grass for animal feed. The 9GL cuts the grass at the base to preserve the stem and leaf, whereas a mulcher destroys the crop.

Q9. Can I customize the paint color to match my tractor fleet?

A9. Yes, as an OEM manufacturer, we can paint the machine in any color you request, whether it’s “John Deere Green,” “Kubota Orange,” or “New Holland Blue,” to match your branding.

Q10. What maintenance is required for the reciprocating cutter bar?

A10. Maintenance is simple: grease the pivot points daily, check the knife sections for sharpness, and ensure the hold-down clips are tight. It is much easier to maintain than a complex gearbox system

Editor: PXY