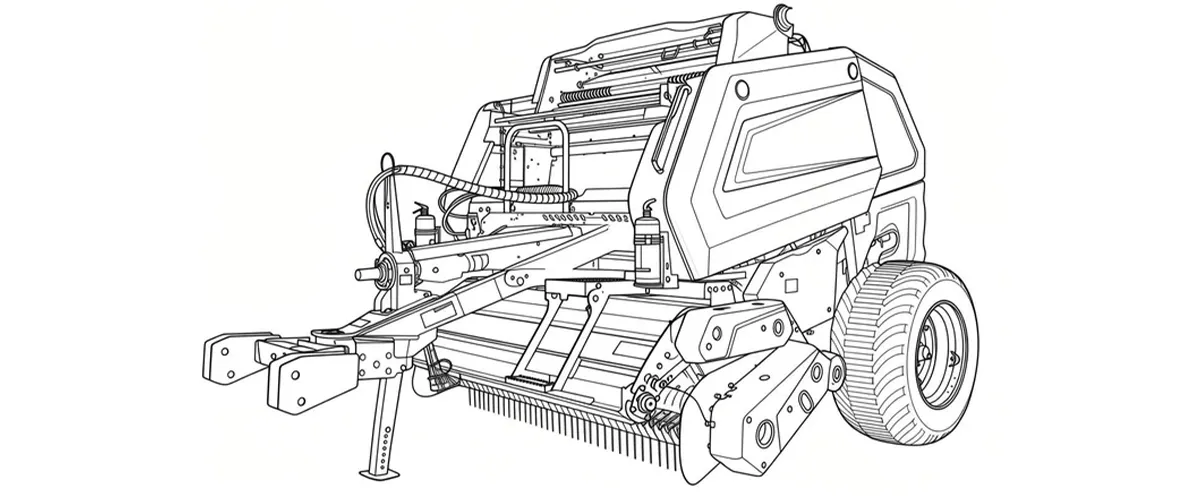

EP-9YG-2.24D-Rundbalpress-S9000

EVER-POWER 9YG-2.24D (S9000-modellen) representerar toppen av dragkraftsteknik, speciellt konstruerad för att övervinna de topografiska utmaningarna i Sydkoreas jordbrukslandskap. Till skillnad från standardmodeller har S9000 en revolutionerande justerbar draganordning med 30° lateral lutningskapacitet och ett förstärkt 20A dubbelsidigt kedjesystem. Med en strukturvikt på 4262 kg och en kompressionskammare med 18 rullar levererar den överlägsen baldensitet (upp till 500 kg/bal) för rishalm och grovfoder, vilket säkerställer fullständig överensstämmelse med koreanska miljö- och subventionsföreskrifter.

1. Tekniska specifikationer: 9YG-2.24D (S9000)

| Inga. | Punkt | Enhet | Specifikation |

|---|---|---|---|

| 1 | Modellnamn | / | 9YG-2.24D rundbalpress (S9000) |

| 2 | Dragkrokstyp | / | Bogserad |

| 3 | Pickupbredd | mm | 2240 |

| 4 | Typ av upphämtningsstruktur | / | Kultyp |

| 5 | Matningsmekanismens struktur | / | Matningsrotor + valstyp |

| 6 | Kompressionskammarstruktur | / | Rullkammare |

| 7 | Kompressionskammarens bredd | mm | 1400 |

| 8 | Kompressionskammardiameter | mm | 1200 |

| 9 | Antal rullarbetskomponenter | st | 18 (Vältar) |

| 10 | Rulldiameter | mm | 222 |

| 11 | Balningsmetod | / | Nätlindning |

| 12 | Nödvändig effekt | kW | 55-100 |

| 13 | Strukturell vikt | kg | 4262 |

| 14 | Kraftuttagsaxelns hastighet | varv/min | 720 |

| 15 | Mått (L × B × H) | mm | 4240 × 3010 × 2450 (i fungerande skick) |

| 16 | Kontroll av fodertäthet | / | Sensorstyrd |

| 17 | Balstorlek (längd × bredd × höjd) | mm | 1300 × 1400 |

| 18 | Baldensitet | kg/m³ | 100–200 |

| 19 | Produktivitet | bal/h | 40–100 |

| 20 | Hjulbas | mm | 2600 |

| 21 | Driftshastighet | km/h | 5–35 |

| 22 | Nätlindningsspecifikation | m | 2000×1,4/rulle |

2. Fem viktiga fakta

1. Förbättrad terränganpassningsförmåga för koreanska risfält

S9000-modellen har en 30° sidolutning och en 100° horisontell styrvinkel i sitt dragsystem, vilket gör att den enkelt kan navigera i den ojämna, kuperade terrängen på sydkoreanska risfält utan att orsaka vridmomentbelastning eller mekaniska fel.

2. Hög baldensitet för överlägset ensilage

S9000 är utrustad med ett 20A dubbelkedjekompressionssystem, vilket avsevärt ökar kompressionstrycket och gör att balpressen kan skapa tätare balar (från 250 kg till 500 kg per bal), idealiskt för högkvalitativ ensilageproduktion, och därmed möta den växande efterfrågan på högdensitetsbalar inom jordbruksindustrin.

3. Efterlevnad av sydkoreanska jordbruksföreskrifter

S9000 är utformad för att hjälpa jordbrukare att följa Clean Air Conservation Act genom att effektivt bala rishalm utan behov av förbränning. Den har en produktivitet på upp till 100 balar per timme, vilket gör den till en snabb och effektiv lösning för att röja åkrar i enlighet med miljöstandarder.

4. Förbättrad markbevaring med bred hjulbas

Trots sin vikt på 4262 kg har S9000 en bred hjulbas på 2600 mm och stora flotationsdäck som fördelar maskinens vikt jämnt, vilket minimerar jordpackning och säkerställer att risets jordstruktur bevaras för framtida plantering.

5. Sömlös integration med lokala traktormärken

S9000 är helt kompatibel med en mängd populära sydkoreanska traktormärken som LS Mtron, TYM och Kubota, och erbjuder flexibla effektkrav från 55–100 kW, vilket gör den anpassningsbar till olika gårdsstorlekar och traktorflottor.

3. Omdefiniera skördeeffektivitet: S9000-fördelen inom koreanskt jordbruk

I den krävande världen av modernt jordbruk, särskilt inom Sydkoreas unika geografiska sammanhang, misslyckas ofta "one-size-fits-all"-metoden för maskiner. Jordbrukare i regioner som Jeollabuk-do och Chungcheongnam-do står inför en dubbel utmaning: små, segmenterade risfält ofta belägna i ojämn, kuperad terräng, och det strikta kravet på balar med hög densitet för att maximera subventionerna för foderbevarande. 9YG-2.24D (S9000) Rundbalpress är inte bara en uppgradering; det är ett specialiserat svar på just dessa behov. Samtidigt som det beprövade axiella flödesmatningssystemet från den klassiska serien bibehålls, introducerar S9000 viktiga strukturella förbättringar som gör den till det självklara valet för professionella entreprenörer och storskaliga kooperativ.

Det definierande kännetecknet för S9000-modellen är dess förbättrade terränganpassningsförmåga. Standardbalpressar med dragkraft lider ofta av styva dragkrokssystem som bara tillåter horisontell justering. Denna begränsning blir en allvarlig belastning när man navigerar i åsar och sluttningar som är typiska för koreanska risfält, vilket ofta leder till momentspänningar och mekaniska fel i drivramen. S9000 löser detta med en nydesignad draganordning med en maximal vridmomentkapacitet på 1000 nm. Avgörande är att den erbjuder en sidledsjustering på upp till 30° och en horisontell styrvinkel på 100°Denna flexibilitet säkerställer att balpressen följer traktorn smidigt över kuperad terräng, vilket skyddar drivlinan.

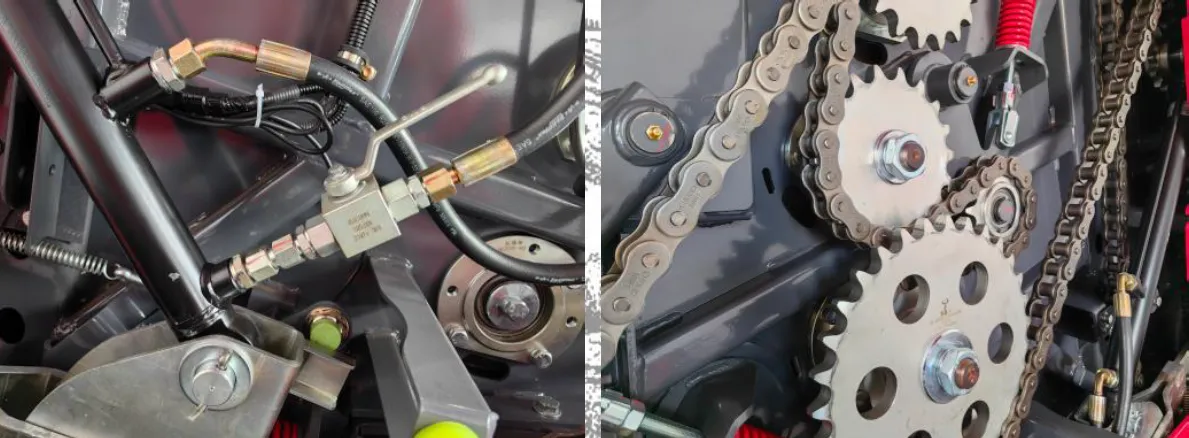

Dessutom prioriterar S9000 baldensitet och hållbarhet. För att erkänna marknadens förskjutning mot högkvalitativt ensilage är S9000:s bakre bal uppgraderad med ett dubbelsidigt 20A kraftigt kedjesystem. Denna robusta transmissionsmekanism ökar avsevärt kompressionstrycket som appliceras på balen, vilket möjliggör densiteter som kan nå mellan 250 kg och 500 kg per bal (beroende på grödans fuktighetshalt).

4. Strategisk marknadsanalys

Att komma in på den sydkoreanska marknaden för jordbruksmaskiner kräver mer än att bara sälja hårdvara; det kräver en djup förståelse av den regelmiljö som kallas Nong-Jeong9YG-2.24D S9000 är konstruerad för att direkt stödja jordbrukare i att följa viktiga myndighetsinitiativ, särskilt gällande hantering av rishalm och miljöskydd.

4.1. Efterlevnad av "Direktstöd för fodergrödor"

Det koreanska ministeriet för jordbruk, livsmedel och landsbygdsfrågor (MAFRA) främjar aktivt produktionen av inhemskt grovfoder för att minska beroendet av importerat foder. "Direktbetalningsprogrammet" erbjuder subventioner till jordbrukare som producerar högkvalitativt ensilage. Kvaliteten bedöms dock ofta utifrån baldensitet och jäsningsframgång. S9000:orna 20A dubbelkedjigt kompressionssystem säkerställer att varje bal uppfyller de höga densitetskrav som krävs för att effektivt utesluta syre, vilket främjar optimal jäsning. Detta hjälper direkt jordbrukare att kvalificera sig för högre subventioner genom att producera rishalm av högkvalitativ foderkvalitet (Nong-lim).

4.2. Miljömandat: Lagen om ren luft

Stränga restriktioner för öppen förbränning av jordbruksbiprodukter har införts över hela Korea för att bekämpa föroreningar från fint damm. Jordbrukare måste nu bala sina halmrester. S9000 möjliggör snabb röjning av åkern med en produktivitet på upp till 100 balar per timme. Dess Axialflödes halvtvångsmatning Mekanismen är särskilt skicklig på att hantera den hårda, ofta fuktiga rishalmen som finns under koreanska höstar, vilket förhindrar de blockeringar som plågar mindre maskiner. Denna tillförlitlighet säkerställer att jordbrukare kan röja åkrar snabbt och följa brännskyddslagar utan att försena planteringen av vintertäckgrödor som råg eller korn.

4.3. Terräng- och markskydd

Koreanska risfält är värdefulla tillgångar och jordpackning är en viktig faktor. Trots sin robusta vikt på 4262 kg är S9000 konstruerad med ett brett hjulspår på 2600 mm och använder stora flotationsdäck. Denna design fördelar maskinens vikt jämnt, vilket minimerar fotavtrycket och minskar djup jordpackning (trågbildning). Dessutom är den unika 30° tiltfäste förhindrar att balpressen gräver ner sig i jorden när den korsar de branta in- och utgångsramperna från terrasserade risfält, vilket bevarar risvallarnas fysiska integritet (Non-du-reong).

5. Arbetssätt och komponentkompatibilitet

Kärntekniken: S9000 arbetar med en sofistikerad princip för kontinuerligt flöde. När enheten bogseras lyfter den 2240 mm breda pickupen – som använder en kamlös fjädertandsdesign – grödan. Den avgörande innovationen är Axiellt flödesmatningssystemTill skillnad från traditionella skruvborrar som trycker grödan mot mitten, tvingar vår kombination av rotor och pinnrulle aktivt materialet in i kammaren. Detta är avgörande för våta grödor (ensilage), eftersom det eliminerar de "döda zonerna" där våt halm vanligtvis samlas och täpps till. Inuti kammaren roterar 18 höghållfasta stålvalsar (Φ222 mm) för att forma balen. Det avancerade sensornätverket övervakar tryckuppbyggnaden, och först när måldensiteten är uppnådd påbörjas nätlindningen.

6. Tillämpningsscenarier

6.1. Sydkorea: Hantering av risstrån

AnsökanS9000 utmärker sig i hanteringen av vått rishalm, vilket är ett stort problem under Sydkoreas monsunsäsong. Maskinens Axiellt flödesmatningssystem förhindrar igensättning, vilket gör det möjligt för jordbrukare att effektivt samla rishalm utan behov av att bränna. Detta hjälper dem att följa Lagen om ren luftvård genom att producera halm för foder eller biomassa, istället för att bidra till luftföroreningar.

6.2. USA: Skörd av majsstjälkar

AnsökanI mellanvästern, där majsstjälkar finns i överflöd efter skörd, är S9000 idealisk för hantering av täta grödorester. Med sin hög baldensitet och höghastighetsdrift, kan jordbrukare röja stora åkrar snabbt och producera täta balar som är enklare att transportera och lagra, vilket förbättrar både foderkvaliteten och biomassautnyttjandet.

6.3. Ryssland: Insamling av vinterveterester

AnsökanRyska jordbrukare som hanterar täta vinterveterester drar nytta av S9000 varaktighet och högt kompressionstryckDen kraftiga 20A dubbelkedjesystem möjliggör skapande av tätare balar, vilket säkerställer att halmen hanteras effektivt, även under tuffa och krävande förhållanden.

6.4. Brasilien: Skörd av sockerrörsrester

AnsökanI Brasilien, där sockerrörsfält lämnar efter sig betydande rester, erbjuder S9000 högdensitetsbalning för att effektivt hantera fibermaterialet. Dess kraftfulla kompressions- och balbildningsmekanism minskar behovet av förbränning, vilket är i linje med Brasiliens hållbara jordbruksmetoder.

6.5. Australien: Balning av vete- och kornhalm

AnsökanI Australiens veteodlingsregioner hanterar S9000 stora mängder vete- och kornhalm, vilket ger höghastighetsdrift (upp till 35 km/h) och jämn baldensitetDetta säkerställer att restprodukter hanteras effektivt samtidigt som markhälsan bibehålls genom att minimera packning.

6.6. Kina: Biomassainsamling för bioenergi

AnsökanSom en del av Kinas energiomställning till biobränslen, S9000:s sensorstyrt densitetssystem optimerar balbildning för användning som biomassabränsle. Maskinens förmåga att skapa mycket kompakta balar effektiviserar transport och lagring, vilket stöder den växande efterfrågan på biomassa som förnybar energikälla.

6.7. Indien: Hantering av risstrån i Punjab

AnsökanI Punjab, där förbränning av rishalm har varit ett stort miljöproblem, hjälper S9000 till att hantera rishalm genom att omvandla den till högkvalitativt foder eller strö. Dess Axiellt flödesmatningssystem gör den lämplig för hantering av den våta och sega halmen som blir kvar, vilket minskar föroreningar och hjälper jordbrukare att uppfylla miljöföreskrifter.

6.8. Argentina: Foderbevarande för boskap

AnsökanPå argentinska gårdar där foderkvaliteten är avgörande används S9000 för att producera högdensitetsensilage balar för djurfoder. Maskinens jämn baldensitet och avancerat nätlindningssystem säkerställa att grovfodret är välbevarat under lagring och transport, vilket förhindrar förstöring och förbättrar foderkvaliteten för nötkreatur.

6.9. Sydafrika: Ensilagebalning för nötkreatursgårdar

AnsökanI Sydafrika är S9000:s förmåga att hantera foder med hög fuktighet gör den till ett idealiskt val för ensilageproduktion. Maskinens hög baldensitet och avancerat utfodringssystem säkerställa produktionen av kompakta, jämna balar som jäser väl, vilket bidrar till bättre ensilagekvalitet för boskapsfoder.

6.10. Ukraina: Balning av majs- och solrosrester

AnsökanUkrainska bönder använder S9000 för att hantera svåra majs- och solrosrester. högdensitetsbalningssystem skapar jämna, kompakta balar som är lätta att transportera, vilket minskar behovet av att bränna åkerrester och bidrar till mer hållbara jordbruksmetoder.

7. Kompatibilitet och uppgraderingsjämförelse

| Särdrag | Standard rundbalpress | EVER-POWER S9000-modellen | Fördel för koreanska användare |

|---|---|---|---|

| Dragkrok | Endast fast/horisontell justering | 30° lutning + 100° vridning justerbar | Förhindrar att dragkroken går sönder på kuperade/terrasserade fält; säkrare svängar. |

| Drivkedjor | Standard enkelkedja | Dubbelsidig 20A kraftig | Hanterar högre vridmoment för tätare balar; längre livslängd. |

| Vikt | Cirka 3000–3500 kg | 4262 kg (strukturell massa) | Större stabilitet och nedåtriktat tryck för balbildning. |

| Kompatibla traktorer | Generisk 80 hk | LS Mtron, TYM, Kubota (55-100kW) | Sömlös kraftuttags- och hydraulikintegration med lokala flottor. |

8. Globala trender inom teknik för foderskörd

Den globala balpressmarknadens utveckling rör sig avgörande mot "Smart densitet" och "Terrängsmidighet." På mogna marknader som Europa och framväxande högteknologiska marknader som Sydkorea skiftar trenden från enkla mekaniska balpressar till maskiner som erbjuder högre densitet för biomassalogistik. Uppkomsten av bioenergikraftverk i Asien har skapat en ny efterfrågan på halmbalar som bränsle, där transporteffektivitet (hög densitet) är av största vikt.

Dessutom innebär arbetskraftsbristen på landsbygden ("urholkade byar") att en enda förare måste uppnå det som tidigare krävdes av ett team. S9000 följer denna trend genom att erbjuda höghastighetsdrift (upp till 35 km/h) och lågt underhållsbehov (inget kamspår), vilket gör att en enda förare kan hantera stora arealer effektivt. Framtiden för balpressning är också sammankopplad; medan S9000 för närvarande använder robusta sensorkontroller, forskar EVER-POWER aktivt på ISOBUS-integration för framtida iterationer för att möjliggöra direkt kommunikation mellan balpress och traktor, en funktion som alltmer efterfrågas av användare av premiumtraktorer som John Deere och Fendt.

9. Om oss | EVER-POWER Fabrikskapacitet och OEM-anpassning

EVER-POWER Machinery Co., Ltd. är inte bara en montör; vi är en heltäckande tillverkare belägen i en nationell ekonomisk och teknologisk utvecklingszon. Vår anläggning sträcker sig över 32 000 kvadratmeter och är utrustad med avancerade intelligenta tillverkningsverktyg, inklusive CNC-laserskärare, robotsvetslinjer och elektrostatiska pulverlackeringssystem. Denna vertikala integration gör det möjligt för oss att erbjuda oöverträffade OEM- och anpassningstjänster.

För våra partners i Sydkorea och övriga världen erbjuder vi omfattande anpassningsmöjligheter för S9000. Detta inkluderar:

- Färgmatchning: Anpassade lackeringsjobb som matchar din återförsäljares varumärke (t.ex. LS Blue, TYM Red).

- Modifiering av dragkrok: Anpassning av dragöglan för att passa specifika dragstångsstandarder som används i lokala regioner.

- Hydraulisk anpassning: Anpassning av hydrauliska kopplingar för att matcha de specifika flödeshastigheterna och anslutningstyperna hos äldre traktormodeller som ofta finns på landsbygden.

- Förstärkt skydd: Lägger till extra skyddsplåtar för underredets skydd i särskilt steniga områden.

10. Kundframgångsfall: Högeffektiv avverkning i Chungcheong-provinsen

"Vi har använt S9000 till våra risfält, och flexibiliteten i dess dragkrokssystem har gjort en enorm skillnad. 30° lutning och 100° svängjustering låter oss arbeta smidigt på våra kuperade fält utan problem. Det har sparat enormt mycket tid, och baldensiteten är utmärkt för ensilage!"

---Soo-Jin från Jeollabuk-do, Sydkorea"S9000 är ett monster när det gäller att göra tätare balar. Vi använder den för majsstjälkar, och 20A-systemet med dubbelkedjor komprimerar balarna verkligen bra. Den extra vikten ger den stor stabilitet, och vi har sett en betydande ökning av vår produktivitet. Den är byggd för att hålla, och jag är glad att vi investerade i den."

---Tom från Kalifornien, USA"Eftersom vi bor i en region med strikta miljöregler har S9000 varit en livräddare. Vi behöver inte längre bränna vår rishalm tack vare det kraftfulla Axial Flow-matningssystemet. Det hanterar den våta halmen perfekt, och vi kan röja våra åkrar på nolltid, samtidigt som vi följer reglerna i Clean Air Conservation Act."

---Min-Ho från Chungcheongnam-do, Sydkorea"På vår nötkreatursgård är ensilagekvaliteten avgörande, och S9000 har överträffat våra förväntningar. Baldensitetskontrollen säkerställer att varje bal är perfekt för jäsning. Den är lätt att använda, och med sin höga hastighet har vi kunnat bala mer effektivt och förbättra kvaliteten på vårt foder."

---Johan från Western Cape, Sydafrika"S9000 har varit ett fantastiskt tillskott till vår vinterveteproduktion. Maskinen är kraftfull och hanterar den hårda, täta halmen utan ansträngning. Vi har sett förbättrad balkvalitet och snabbare röjning. Dessutom innebär kompatibiliteten med våra lokala traktorer att vi inte behövde oroa oss för några tekniska problem."

---Mikhail från Krasnodar, Ryssland

11. Utbytbara delar

11.1 Växellåda:

Kompatibla modeller: EP-Rundbalpressserien (rundbalpress, utväxlingsförhållande 1:2, kompatibel med 35 mm 6-splinesaxel).

Användningsområde: Överför kraftuttagskraft till balpressmekanismen, lämplig för New Holland 630 eller John Deere 535. Parametrar: Vridmoment > 500 Nm, 20% bränslebesparing.

Varför välja denna växellåda: Anpassningsbar storlek (reducerbar till 250-300 mm), resistent mot viskösa föroreningar (gummiångor), IP65-skydd. Kraftuttagsaxel:

Kompatibla modeller: EP-PTO-serien (1-3/8" Z6-spline, justerbar längd 600-1200 mm).

Användningsområde: Ansluter traktorn till balpressens huvuddrivning, lämplig för typ 9YG-1.0C. Momentöverföringseffektivitet >95%, kompatibel med SAE/EURO-flänsar.

11.2 Kedjor & Kedjehjul:

Kompatibla modeller: ANSI #50/#60 kedjor, med EP-drev (stigning 12,7–19,05 mm, rulldiameter 10–12 mm).

Användningsområde: Används i transportband eller bindningsmekanismer, lämplig för transport av halm i fyrkants-/rundbalspressar. Bredd 25-40 mm, slitstarkt stålmaterial.

11.3 Kopplingar:

Kompatibla modeller: EP-koppling 200-serien (momentanpassning 500-1000 Nm).Användning: Ansluter växellådan till balpressvalsen, dämpar vibrationer.

11.4 Hydraulcylinder:

Hydraulcylinder: EP-HC-serien (diameter 50–100 mm, slaglängd 300–600 mm), lämplig för ballyftning.Lager och tätningar: 6208-2RS-lager, L10 livslängd >10000 timmar, dammtät tätning.Kompatibilitetstabell: Helt utbytbar med Comer 250T (momentmatchning, endast 35% av priset); flänsen matchar nordamerikanskt 4-bults kraftuttagsmönster.

12. Andra produkter i samma serie (2.24D)

Vanliga frågor (FAQ)

F1. Varför är S9000-modellens justerbara dragkrok viktig för koreanska risfält?

F2. Hur förbättrar 20A dubbelsidiga kedjesystem balkvaliteten för ensilage?

F3. Kan 9YG-2.24D S9000 hantera vått rishalm utan att det täpps till under monsunsäsongen?

F4. Vilken är den rekommenderade hästkraften för traktorn för att köra S9000 effektivt i backar?

F5. Är 9YG-2.24D S9000 kompatibel med LS Mtron- och TYM-traktorer?

F6. Vilka är transportdimensionerna, och är det enkelt att flytta mellan små fält?

F7. Hur hjälper den här maskinen jordbrukare att följa det koreanska förbudet mot att bränna halm?

F8. Erbjuder EVER-POWER reservdelar som 20A-kedjor och pickup-pinnar i Korea?

F9. Vad är den förväntade livslängden för valsar jämfört med bandpressar?

F10. Kan jag anpassa balpressens färg så att den matchar min befintliga traktorflotta?

Redaktör: PXY