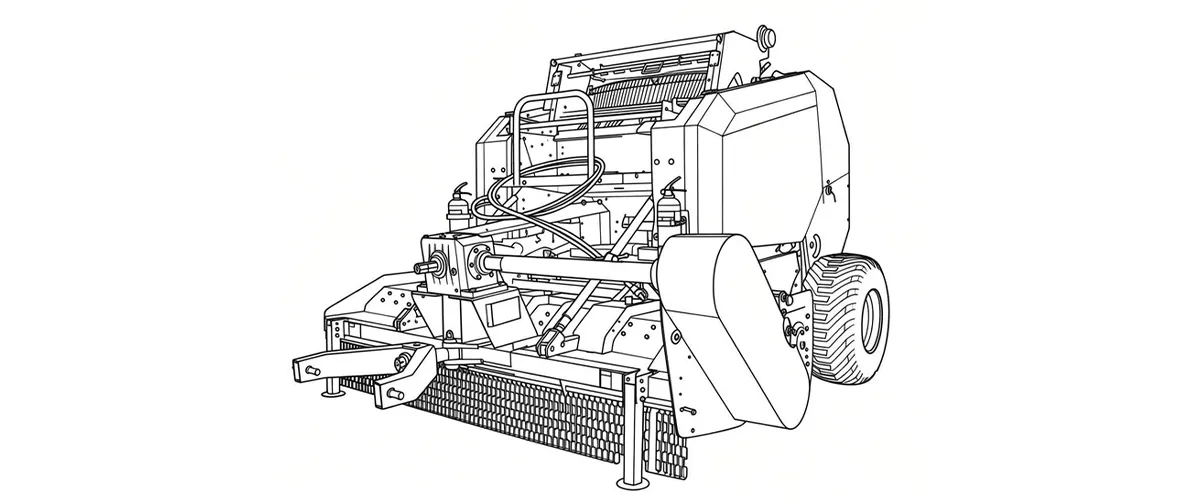

EP-9YG-1.0C rundbalpress

The 9YG-1.0C Round Baler distinguishes itself from standard forage equipment through its proprietary interchangeable pickup system, specifically the “Hammer Claw” configuration designed for pulverizing and baling standing corn stalks in a single operation. Unlike the smaller 9YG-1.0 or the larger 2.24D models, the 1.0C is engineered with a reinforced chassis weighing 3198kg and utilizes dual-sided 16A industrial chains to handle the extreme torque required for high-density silage (up to 200kg/m³). This machine is critical for markets like South Korea, where the “Clean Air Conservation Act” restricts field burning, necessitating efficient residue recovery solutions that integrate crushing, feeding, and binding into one seamless workflow.

1. Technical Specifications: 9YG-1.0C Data Sheet

| Item No. | Parameter Name | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-1.0C Round Baler |

| 2 | Hitch Type | / | Trailed |

| 3 | Pickup Width | mm | 2400 |

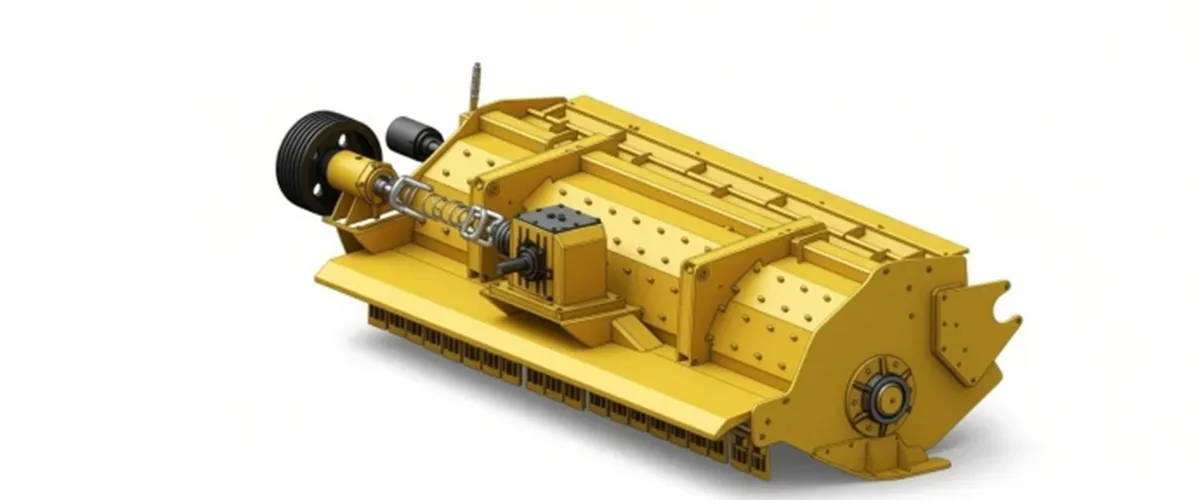

| 4 | Pickup Structure Type | / | Vane + Pick-Up Teeth + Roller |

| 5 | Feeding Mechanism | / | Feeding Rotor + Roller |

| 6 | Compression Chamber Width | mm | 1250 |

| 7 | Compression Chamber Diameter | mm | Φ1000 |

| 8 | Number of Compression Rollers | pcs | 16 (rollers) |

| 9 | Roller Diameter | mm | Φ222 |

| 10 | Binding Method | / | Automatic Net Binding |

| 11 | Matched Power | Kw/hp | ≥69.8 / 95 |

| 12 | Structural Weight | kg | 3198 |

| 13 | PTO Speed | r/min | 540 |

| 14 | Dimensions (L×W×H) | mm | 3800 × 2850 × 2200 |

| 15 | Forage Density Control | / | Sensor-Controlled |

| 16 | Forage Size (Dia × Width) | mm | Φ1000 × 1250 |

| 17 | Forage Density | Kg/m³ | 115 ~ 200 |

| 18 | Productivity | Bales/h | 40 ~ 80 |

| 19 | Wheelbase | mm | 2100 |

| 20 | Operating Speed | Km/h | 5 ~ 20 |

| 21 | Net Wrap Specification | / | 2000m x 1.25m per roll |

It's smaller in size and lightweight.

2. Five Critical Engineering Facts

- 1. Hammer Claw Technology: Unique pickup mechanism replaces standard tines with heavy hammers, allowing direct harvest of standing stalks without pre-shredding.

- 2. Reinforced Transmission: Upgraded front and rear chambers driven by 16A heavy-duty double chains, offering 40% higher tensile load capacity than standard chains.

- 3. High-Density Compression: 16 steel rollers create dense bales (115~200 kg/m³), essential for anaerobic fermentation in silage production.

- 4. Optimized Dimensions: The Φ1000 × 1250 mm bale size is perfectly calibrated for standard Asian logistics pallets and automated feeding systems.

- 5. Power Requirement: Requires ≥95 HP (69.8 kW), ensuring compatibility with common mid-range tractors like LS, Kubota M-Series, and John Deere 6 Series.

3. Operational Mechanics: Why the Hammer Claw System Changes the Game

The agricultural machinery sector has long struggled with the inefficiency of harvesting crop residues, particularly tough maize stover. Traditional methods require multiple passes: first shredding, then raking, and finally baling. The 9YG-1.0C Round Baler fundamentally alters this workflow through its engineered "Hammer Claw" pickup system. Unlike standard spring-tooth pickups that merely lift windrowed material, the Hammer Claw system (featuring 18 robust claws) acts as a primary processor. As the tractor moves forward, these claws strike the standing stalk at high velocity, shattering the fibrous structure before lifting it into the feed chamber. This integrated crushing action is vital for silage quality; by breaking the stem nodes, the surface area for fermentation bacteria is increased, and the air pockets within the bale are significantly minimized.

Once the material enters the throat, the 9YG-1.0C utilizes a "Force Feeding" mechanism combining an auger and a tine roller. This creates a continuous, high-volume flow of biomass into the compression chamber, effectively preventing the "choking" often seen in belt balers when handling wet crops. Inside the chamber, 16 high-strength steel rollers (Φ222mm) take over. We utilize cold-drawn seamless steel for these rollers, carburized to resist the abrasive wear of soil-laden straw. The rollers rotate the bale core, applying centripetal compression force. As the bale grows, the hydraulic density sensors monitor internal pressure. Upon reaching the preset density (up to 400 jin/200kg), the automatic net binding system engages, wrapping the bale in under 10 seconds to lock in the density before ejection. This mechanical precision ensures that every bale produced in the fields of Chungcheong or Hokkaido maintains structural integrity during transport.

4. Environmental Laws

The deployment of the 9YG-1.0C is not merely an operational upgrade; it is a strategic response to tightening global environmental regulations.

In South Korea, the Ministry of Environment has aggressively enforced the Special Act on the Reduction and Management of Fine Dust. Open burning of agricultural by-products, once a common practice for clearing corn and rice fields, now attracts severe financial penalties due to its contribution to seasonal PM2.5 spikes. The 9YG-1.0C provides farmers with a compliant alternative: converting potential waste into a tradable commodity (livestock feed or biomass fuel). By removing the residue cleanly, farmers avoid fines and can often claim government subsidies available for eco-friendly straw treatment.

This trend extends far beyond Korea. In the European Union, under the Common Agricultural Policy (CAP) eco-schemes, soil health and carbon management are paramount. While incorporating some straw is beneficial, excessive corn stover left on the field can harbor pests (like the corn borer) and immobilize soil nitrogen during decomposition.

The 9YG-1.0C allows for precise residue management—harvesting the bulk for bio-energy or bedding while leaving the stubble. Similarly, in China's northeast "Black Soil" region, strict straw utilization quotas mandate that farmers baling straw must ensure a clean pick-up to avoid soil contamination in the fodder.

5. Interoperability: Brand & Component Compatibility

The 9YG-1.0C is designed with ISO standard interfaces to ensure seamless integration with major global tractor brands and consumable supplies.

| Component System | EVER-POWER Specification | Compatible / Replacement For |

|---|---|---|

| Tractor PTO | 540 RPM, 6-Spline or 8-Spline | Compatible with LS Tractor (MT7 Series), Kubota (M5/M6 Series), John Deere (6M Series) |

| Net Wrap | 1230mm / 1250mm Standard Rolls | Universal fit for Tama, Novatexoch Piippo net wraps. |

| Hydraulics | Dual SCV Required (Pressure/Return) | Standard ISO 7241-1 A Quick Couplers (Parker/Eaton style) |

| Drive Chain | 16A / 16A-2 Heavy Duty | Standard industrial sizing, replaceable with Tsubaki or Renold equivalents. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

6. Market Trend Analysis: The Shift to High-Density Silage

The agricultural machinery market in East Asia, particularly South Korea and Japan, is undergoing a significant pivot towards "Densified Biomass Logistics." Due to the rising cost of imported feed and the scarcity of arable land, there is a premium on maximizing the nutritional value preserved per cubic meter of storage. This trend is driving the obsolescence of low-density square balers in favor of high-compression round balers like the 9YG-1.0C.

Furthermore, labor shortages in rural demographic sectors are pushing the market towards automation; the 9YG-1.0C's ability to crush and bale in one pass eliminates the need for a separate tractor and operator for raking, aligning perfectly with the "Smart Farming" initiatives promoted by the Korean government (MAFRA). We also observe a growing demand for machines that can handle "Roughage Fermentation," where the specific hammer claw action aids in breaking down lignin before the wrapping process even begins.

7. Application Scenarios

1. Maize Stover Collection

Scenario: In regions like South Korea and Japan, farmers grow maize and face the challenge of managing tough, fibrous corn stalks.

Application: The Hammer Claw pickup system allows farmers to directly harvest standing maize stalks without the need for shredding or raking. This reduces labor and fuel costs, making it ideal for high-yield corn farms.

2. Rice Straw Baling in Asia

Scenario: In countries like China and South Korea, rice paddies produce large amounts of rice straw after harvest.

Application: The Hammer Claw system easily collects rice straw, making it ready for storage, silage, or biofuel production. Its ability to handle wet, heavy crops ensures it is ideal for post-harvest rice residue management.

3. Silage Production for Dairy Farms

Scenario: Livestock operations in Korea and Japan demand high-quality silage for feed, especially for Hanwoo beef and dairy cattle.

Application: With its high-density compression mechanism and Force Feeding system, the 9YG-1.0C produces dense bales (115–200 kg/m³) ideal for silage, preserving nutrients and improving feed efficiency for livestock.

4. Straw Recovery for Bio-Energy

Scenario: In China, straw burning is regulated, and alternative uses such as bio-energy are growing.

Application: The 9YG-1.0C can efficiently collect and bale straw for conversion into biomass fuel, ensuring compliance with environmental regulations while providing a renewable energy source.

5. Wet Crop Handling in Heavy Rainfall Areas

Scenario: Regions like Gangwon-do in South Korea experience heavy rainfall during harvest seasons, creating challenges in baling wet crops.

Application: The Force Feeding mechanism and heavy-duty transmission system ensure smooth operation even with wet, dense crops like silage, preventing clogging and allowing for continuous operation.

6. Corn Stalk Management in U.S. & Canada

Scenario: In the U.S. Midwest and Canada, farmers harvest corn for cellulosic ethanol production.

Application: The 9YG-1.0C is ideal for efficiently collecting corn stover for use in biofuels. The Hammer Claw pickup ensures that the stalks are cleanly harvested without soil contamination, which is crucial for bioenergy applications.

7. Pasture Grass Collection for Livestock Bedding

Scenario: Livestock farms in rural areas often require bulk straw or grass for bedding material.

Application: The pickup width of 2400mm and the high-density compression system produce consistent, dense bales of grass, ideal for bedding and reducing the need for costly external bedding supplies.

8. Efficient Harvest in Cold Climates

Scenario: In cold regions like Hokkaido (Japan) or Chungcheong (South Korea), there is limited time for harvest before the first frost.

Application: The 9YG-1.0C's ability to collect and bale standing crops in a single pass minimizes time spent in the field, allowing farmers to clear fields rapidly before adverse weather conditions arrive.

9. Switching Between Crop Types

Scenario: Farms that grow different types of crops need machinery that can adapt to various harvesting needs.

Application: The interchangeable Hammer Claw and Spring Tooth pickup systems allow farmers to quickly switch between harvesting corn and grass with minimal downtime, making the 9YG-1.0C ideal for versatile farm operations.

10. Straw Collection for Animal Feed

Scenario: Farmers in regions with a growing livestock sector, such as Korea, need to collect clean straw for animal feed.

Application: The clean pickup of standing stalks ensures that the 9YG-1.0C produces bales that meet the hygiene standards required by the livestock industry, particularly for animals like Hanwoo beef.

8. About us | EVER-POWER Manufacturing

At EVER-POWER, we understand that a baler operating in the flat plains of Heilongjiang faces different challenges than one working the terraced fields of Gangwon-do. Our factory offers robust OEM/ODM customization services for the 9YG-1.0C platform. We can modify the pickup width to suit narrow transport roads, adjust the drawbar geometry for specific tractor hitches, and apply corrosion-resistant coatings specifically for high-humidity coastal regions. Our production line adheres to strict ISO 9001 quality controls, ensuring that every weld on the 3-ton chassis is tested for stress resilience. We invite distributors to collaborate on localized specifications.

9. Customer Success Story:

"I’ve been using the 9YG-1.0C for the past season, and I have to say, the Hammer Claw system is a game-changer. It handles standing corn stalks with ease, and I no longer need to worry about shredding or raking before baling. It’s made my life so much easier and saved me so much time."

— Joon, Farm Owner in South Korea

"I’ve had a few different balers, but the 9YG-1.0C stands out. The reinforced transmission system is really impressive. Even when dealing with heavier crops, I’ve never had an issue with chain wear. The build quality is fantastic, and the machine feels like it’s built to last."

— David, Equipment Operator in Japan

"As a first-time user of a round baler, I was a bit skeptical at first. But after getting the 9YG-1.0C, I’m convinced. The operation is smooth, and it’s super easy to integrate with our LS tractor. I’m getting a much better yield from my fields with less fuel and less labor. It’s been a huge improvement!"

— Sung, Small Farm Owner in South Korea

"The customer service from EVER-POWER was fantastic when we inquired about the baler. They provided all the technical details we needed, and the machine arrived right on time. The baler itself has been a perfect fit for our needs—it can handle roughage, and the bale density control is excellent."

— Anna, Livestock Farmer in Korea

"I’ve used a lot of balers, but the 9YG-1.0C has really impressed me with its heavy-duty design. The machine doesn’t skip a beat, even with tough, fibrous stalks. Plus, the customizable features like the PTO shaft and drawbar geometry made it easy to fit with our existing tractors. Worth every penny!"

— Martin, Agricultural Equipment Dealer in China

10. Replaceable parts

10.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:

Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

10.2 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

10.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

10.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

Frequently Asked Questions (FAQ)

Q1. How does the 9YG-1.0C hammer claw pickup differ from standard spring teeth for baling corn?

A1. The hammer claw system is specifically engineered to crush and lift standing corn stalks directly from the soil, eliminating the need for a separate shredding or raking pass, whereas standard spring teeth are designed primarily for already-cut windrowed grass or rice straw.

Q2. What is the approximate price range for the 9YG-1.0C round baler delivered to Incheon port, South Korea?

A2. The price varies based on customization and shipping volume, but generally, our factory-direct pricing is significantly more competitive than European brands; please click "Get a Quote" for a precise CIF Incheon estimate based on current freight rates.

Q3. Can this round baler effectively handle wet silage crops without clogging the feeding chamber?

A3. Yes, the 9YG-1.0C features a "Force Feeding" system with an integrated auger and tine roller that actively pushes wet, heavy biomass into the chamber, preventing the slippage and clogging issues common in belt-type balers.

Q4. Does EVER-POWER supply replacement 16A heavy-duty chains and rollers for maintenance?

A4. Absolutely, we maintain a full inventory of spare parts, including the specialized 16A double-row chains and hardened rollers, available for rapid international shipping to ensure your harvest season is not interrupted.

Q5. Is the 9YG-1.0C compatible with LS Tractors or Kubota models commonly used in Korea?

A5. Yes, as long as your tractor has at least 95 horsepower (69.8 kW) and a standard PTO output, the 9YG-1.0C is fully compatible with major brands like LS, TYM, and Kubota found in the Korean market.

Q6. How does the net binding system compare to twine binding for outdoor bale storage?

A6. The automatic net binding system provides much better weather protection and shape retention than twine, shedding water more effectively and reducing spoilage, which is critical for outdoor storage in humid climates.

Q7. What maintenance is required for the hammer claws after a heavy harvest season?

A7. You should inspect the hammer claws for wear or deformation after each season; while they are hardened for durability, replacing worn claws ensures optimal crushing efficiency and prevents vibration issues in the pickup mechanism.

Q8. Can I customize the color of the baler to match my dealership's brand identity?

A8. Yes, as an OEM manufacturer, EVER-POWER offers full color and branding customization services, allowing you to align the machine's appearance with your existing fleet or dealership requirements.

Q9. What safety features are included to protect the operator during bale ejection?

A9. The machine includes hydraulic safety locks for the rear gate, overload protection clutches on the PTO shaft, and clear safety signage to ensure the operator remains safe during the ejection and binding cycles.

Q10. How quickly can you ship a container of 9YG-1.0C balers to Southeast Asia or Korea?

A10. Our standard production lead time is 15-20 days, and shipping to major ports like Busan or Incheon typically takes an additional 5-10 days, ensuring you receive equipment well before the harvest deadline.

Ready to Optimize Your Harvest Efficiency?

Contact us today for a detailed spec sheet, dealership opportunities, and a competitive price quote for the South Korean market.

📧 Email: [email protected]

Editor: PXY