EP-9YG-2.24D சுற்று பேலர்

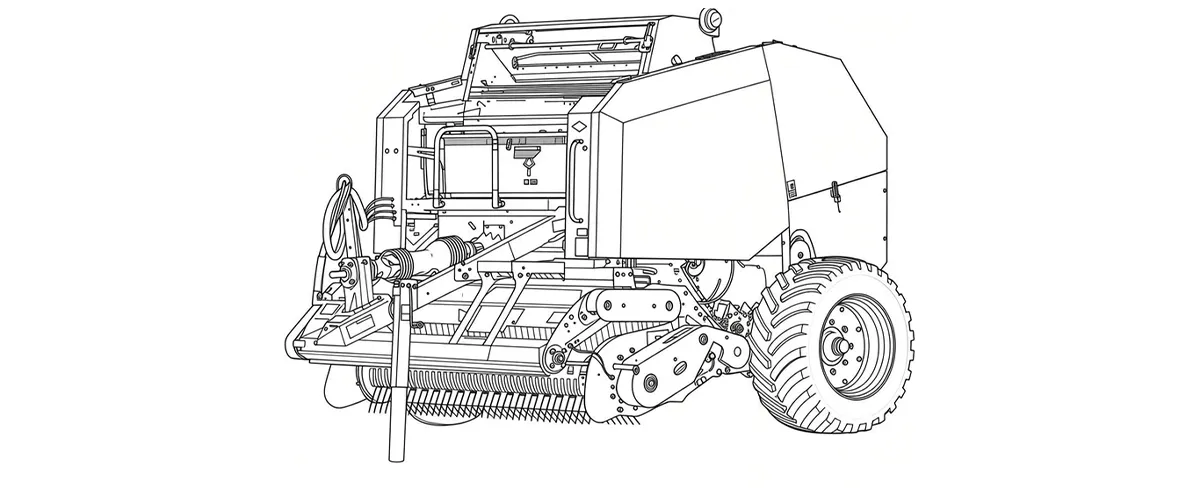

The EVER-POWER 9YG-2.24D is a high-performance traction-type round baler designed to meet the rigorous demands of modern agriculture. With a 2.24m pickup width and innovative axial flow technology, it excels in harvesting corn, rice straw, wheat, and soybean stalks. Specifically optimized for the South Korean agricultural landscape, this machine addresses local soil compaction regulations and efficiency needs. Engineered for durability with a 3922 kg structure mass and 18 heavy-duty rollers, it ensures high-density bales (100-200 kg/m³) every time.

1. Technical Specifications & Performance Parameters

| இல்லை. | பொருள் | அலகு | விவரக்குறிப்பு |

|---|---|---|---|

| 1 | மாதிரி பெயர் | / | 9YG-2.24D Round Baler |

| 2 | ஹிட்ச் வகை | / | பின்தங்கிய |

| 3 | பிக்அப் அகலம் | மிமீ | 2240 |

| 4 | பிக்அப் கட்டமைப்பு வகை | / | பந்து வகை |

| 5 | உணவளிக்கும் பொறிமுறை அமைப்பு | / | ஃபீடிங் ரோட்டார் + ரோலர் வகை |

| 6 | சுருக்க அறை அமைப்பு | / | ரோலர் சேம்பர் |

| 7 | சுருக்க அறை அகலம் | மிமீ | 1400 |

| 8 | சுருக்க அறை விட்டம் | மிமீ | 1200 |

| 9 | ரோலர் வேலை செய்யும் கூறுகளின் எண்ணிக்கை | பிசிக்கள் | 18 (உருளைகள்) |

| 10 | ரோலர் விட்டம் | மிமீ | 222 |

| 11 | பேலிங் முறை | / | வலை மடக்குதல் |

| 12 | தேவையான சக்தி | கிலோவாட் | 55-100 |

| 13 | கட்டமைப்பு எடை | கிலோ | 3922 |

| 14 | PTO வெளியீட்டு தண்டு வேகம் | r/நிமிடம் | 720 |

| 15 | பரிமாணங்கள் (L × W × H) | மிமீ | 4110 × 3010 × 2450 (working condition) |

| 16 | தீவன அடர்த்தி கட்டுப்பாடு | / | சென்சார் கட்டுப்பாட்டில் உள்ளது |

| 17 | பேல் அளவு (நீளம் × அகலம் × உயரம்) | மிமீ | 1300 × 1400 |

| 18 | பேல் அடர்த்தி | கிலோ/மீ³ | 100–200 |

| 19 | தயாரிப்பு | மணி/மணி | 40–100 |

| 20 | வீல்பேஸ் | மிமீ | 2600 |

| 21 | இயக்க வேகம் | கிமீ/ம.மீ. | 5–35 |

| 22 | நெட் ரேப் விவரக்குறிப்பு | மீ | 2000×1.4 / ரோல் |

2. Five KEY FACTS

2.1. High Efficiency and Fast Operation

The 9YG-2.24D Round Baler is designed to handle high-density bales (100–200 kg/m³) at a productivity rate of 40–100 bales per hour. This makes it an excellent choice for large-scale operations, significantly increasing harvesting efficiency. Its maximum operating speed of 35 km/h allows farmers to clear fields rapidly between planting and harvest seasons.

2.2. Axial Flow Semi-Forced Feeding Mechanism

Unlike traditional balers with cam-track pickups, the 9YG-2.24D uses a proprietary Axial Flow Semi-Forced Feeding Mechanism. This advanced design increases the feeding rate, reduces power consumption, and minimizes blockages, especially during wet rice straw harvesting in South Korea’s monsoon season.

2.3. Robust Construction for Durability

With a structural mass of 3922 kg, the 9YG-2.24D is built for heavy-duty use. It features an 18-roller compression chamber that ensures uniform pressure application and consistent bale density. This design also provides stability on uneven terrain, making it ideal for the diverse conditions of South Korea’s agricultural fields.

2.4. Compliance with South Korean Environmental Regulations

The 9YG-2.24D is optimized for South Korea’s stringent agricultural regulations. It helps farmers meet the Clean Air Conservation Act, as it efficiently bales rice straw for use as livestock feed instead of burning it, contributing to the reduction of fine dust pollution. The baler’s design also minimizes soil compaction, meeting local land preservation standards.

2.5. Flexible Power and Compatibility

The 9YG-2.24D operates with tractors ranging from 55 kW to 100 kW, making it versatile and adaptable to different farming operations. It is compatible with popular tractor brands in South Korea, including LS Mtron, TYM, மற்றும் John Deere, providing farmers with flexibility in choosing the right equipment for their needs.

3. Revolutionizing Forage Harvesting: Why the 9YG-2.24D is the Choice for Global Farmers

In the evolving landscape of global agriculture, particularly in markets like South Korea, the United States, and Russia, the demand for machinery that can handle high-moisture crops and tough residues is at an all-time high. The 9YG-2.24D Round Baler represents a significant leap forward in harvesting technology. Unlike traditional models that rely on cam-track pickups which are prone to wear and mechanical failure, the 9YG-2.24D utilizes a state-of-the-art Axial Flow Semi-Forced Feeding Mechanism. This proprietary design not only reduces power consumption but also increases the feeding rate significantly, minimizing the probability of grass blockage.

Efficiency is the cornerstone of the 9YG-2.24D. By eliminating the cam and guard ring in the pickup mechanism, maintenance downtime is drastically reduced, allowing for higher operating speeds of up to 35 km/h. This is crucial for contractors who need to clear fields quickly between harvest and planting windows. The machine creates standard Φ1300×1400 mm bales, utilizing a sophisticated net binding system that ensures bale integrity during transport and storage.

Whether you are baling corn stalks in the American Midwest or managing rice paddies in Jeollanam-do, the 9YG-2.24D delivers a productivity rate of 40-100 bales per hour, doubling the efficiency of many conventional balers in its class.

Furthermore, the robust construction of the 9YG-2.24D, with a structural mass of 3922 kg, ensures stability on uneven terrain. The 18-roller compression chamber is engineered to apply uniform pressure, resulting in consistent bale density controlled by advanced sensors. This machine is not just an implement; it is a strategic asset for agricultural enterprises looking to optimize their biomass collection and forage preservation processes while adhering to the highest standards of mechanical reliability.

4. Market Analysis: Adapting to South Korea's Agricultural Regulations

The South Korean agricultural sector is currently undergoing a significant transformation driven by government policies aimed at sustainable farming and environmental protection. One of the critical challenges for Korean farmers is the management of rice straw (Nong-lim) after harvest. The 9YG-2.24D Round Baler is specifically configured to address the nuances of this market. In Korea, the "Direct Payment Program for Preserving Field Fodder" encourages farmers to harvest rice straw for cattle feed rather than burning it. Our baler's high-density compression capability ensures that the harvested straw meets the quality standards required for premium livestock feed, maximizing the subsidies farmers can receive.

Furthermore, environmental regulations in South Korea, such as the Clean Air Conservation Act, strictly prohibit the open burning of agricultural by-products to combat fine dust pollution. This mandates the use of efficient baling equipment. The 9YG-2.24D's ability to handle wet and tough straw without clogging makes it an ideal solution for complying with these strict environmental laws. Unlike smaller, lighter balers that may struggle with the density of damp rice straw, our heavy-duty rollers and axial flow system ensure continuous operation, allowing farmers to clear fields rapidly before winter frosts set in.

We also address soil compaction concerns. Korean regulations regarding land preservation are becoming stricter. Despite its robust weight of 3922 kg, the 9YG-2.24D is designed with a wide wheel track (2600 mm) and utilizes flotation tires that distribute weight evenly. This design minimizes soil compaction, preserving the paddy's soil structure for the next planting season, which is a key compliance factor for land preservation laws in East Asia.

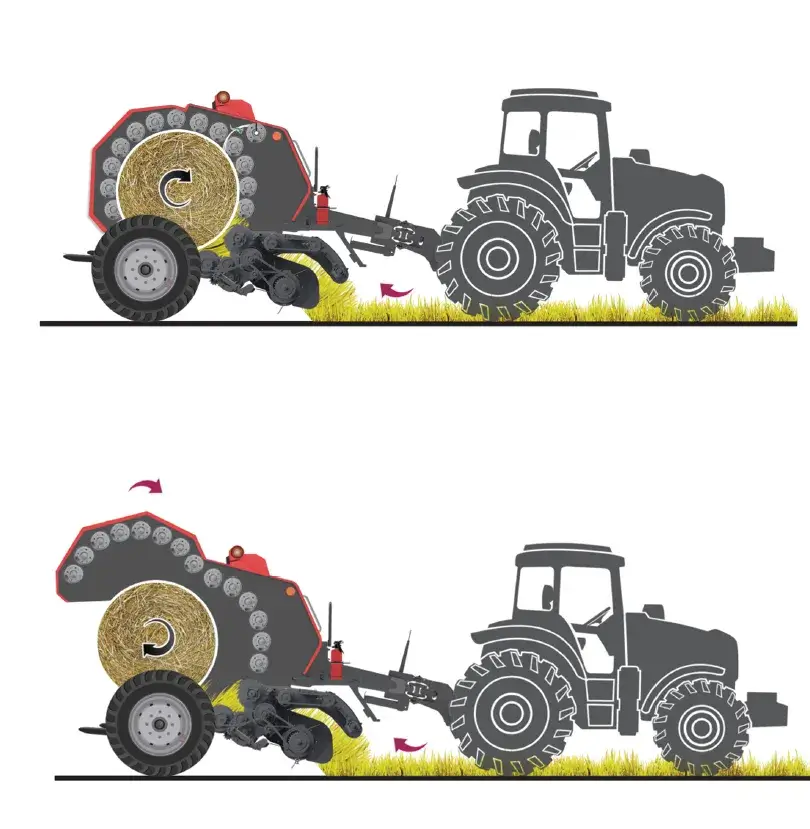

5. Working Principle, Material Technology & Compatibility

வேலை செய்யும் கொள்கை: The 9YG-2.24D operates on a "Pick-up, Feed, and Roll" continuous cycle. As the tractor tows the unit, the spring-tooth pickup lifts the windrowed crop. The core innovation lies in the Axial Flow Feeding System. Instead of a complex cam track that guides the tines (a common point of failure), our design uses a direct rotor and tine interaction to force the crop into the chamber. Inside, 18 high-strength steel rollers rotate to roll the crop into a tight cylinder. Once the preset density is reached, sensors trigger the net binding mechanism, wrapping the bale securely before ejection.

Material Excellence: The rollers are manufactured from reinforced alloy steel with a diameter of 222mm, treated for wear resistance against abrasive crops like rice straw. The chassis undergoes a rigorous electrostatic powder coating process to resist corrosion, essential for the humid climates of Korea and Southeast Asia.

6. Compatibility and Component Comparison

| Component / Feature | Generic Standard Baler | EVER-POWER 9YG-2.24D | Compatible Tractor Brands (Examples) |

|---|---|---|---|

| Pickup Mechanism | Cam Track (High Maintenance) | No Cam Track (Low Maintenance) |

|

| Feeding Type | Standard Auger | Axial Flow Semi-Forced | |

| Roller Count | 14 - 16 Rollers | 18 Heavy Duty Rollers | |

| Power Requirement | 60-80 kW | 55-100 kW (Flexible Range) | |

| Binding System | Twine or Net | High-Speed Net Wrapping |

7. Global Round Baler Market Trends Analysis

The agricultural machinery market is witnessing a decisive shift towards high-density automation மற்றும் durability. Current trends indicate that farmers are moving away from small square balers towards large round balers due to labor shortages—a critical issue in South Korea's aging farming population. The trend is "One Man, One Machine." The 9YG-2.24D aligns with this by offering high throughput that allows a single operator to clear vast areas efficiently.

Another significant trend is the utilization of biomass. With the rise of bio-energy plants, the demand for straw bales as fuel is increasing. This requires bales that are denser and better shaped for transport logistics. The 9YG-2.24D's sensor-controlled density ensures that every bale is optimized for transport efficiency, reducing the cost per ton for logistics companies. We are also seeing a trend towards "Smart Implements," and our sensor-based density control is a step towards full ISOBUS compatibility in future iterations.

8. Application Scenarios

8.1. South Korea: Rice Straw Management

Application: The 9YG-2.24D excels in managing wet rice straw in South Korea, addressing the country’s strict environmental regulations against open burning. It helps farmers efficiently harvest rice straw for livestock feed while complying with the Clean Air Conservation Act. The baler’s robust construction and axial flow feeding mechanism prevent clogging, even in wet conditions, ensuring optimal performance during the monsoon season.

8.2. United States: Corn Stalk Harvesting

Application: In the U.S., particularly in the Midwest, the 9YG-2.24D can be used for harvesting corn stalks after the main harvest. Its high-density baling capability and fast operational speed (up to 35 km/h) make it ideal for clearing large fields quickly, with productivity rates of up to 100 bales per hour. It can handle large volumes of dry residue efficiently.

8.3. Russia: Winter Wheat Residue Management

Application: Russian farmers dealing with large winter wheat fields benefit from the 9YG-2.24D's ability to handle tough, dense straw. The machine’s ability to operate in challenging conditions and its robust design make it well-suited for the country’s varied and often rough terrain, enabling fast, efficient residue management ahead of spring planting.

8.4. China: Biomass Collection for Bioenergy Plants

Application: In China, the growing bioenergy sector requires the collection of straw and other crop residues for use as biomass. The 9YG-2.24D's sensor-controlled density system ensures that each bale is optimized for transport efficiency, contributing to the increasing demand for biomass as an energy source in the country’s energy transition.

8.5. India: Rice Straw Management in Punjab

Application: In India, particularly in Punjab, rice straw burning is a major environmental issue. The 9YG-2.24D offers an effective solution for farmers by efficiently baling rice straw for use as livestock feed or bedding. This helps reduce air pollution while increasing the farmers' productivity through high-density bales that are easy to handle.

8.6. Brazil: Sugarcane Residue Harvesting

Application: Brazilian farmers can use the 9YG-2.24D for managing sugarcane residues. The baler’s high bale density and robust construction make it capable of handling the tough, fibrous material left behind after sugarcane harvesting. The machine’s speed and productivity would significantly boost operational efficiency during the post-harvest period.

8.7. Australia: Wheat and Barley Straw Collection

Application: Australian farmers, particularly in the wheat-growing regions, would benefit from the 9YG-2.24D’s ability to bale wheat and barley straw efficiently. The 9YG-2.24D provides excellent compression and can operate on the country’s large, flat fields, helping with residue management and reducing the need for burning, which aligns with the nation's environmental goals.

8.8. Argentina: Forage Preservation for Livestock

Application: In Argentina, where livestock farming is a significant part of the agricultural sector, the 9YG-2.24D could be used for baling high-quality forage like alfalfa and clover for silage. The advanced net wrapping system ensures that the bales are tightly secured, preventing spoilage during transport and storage, which is essential for livestock feed quality.

8.9. Ukraine: Corn and Sunflower Straw Baling

Application: Ukrainian farmers can use the 9YG-2.24D to collect and bale corn and sunflower residues. The baler’s axial flow feeding system ensures smooth operation even with the tough, fibrous material left after crop harvesting, offering an efficient way to handle large quantities of residue and reducing field residue burning.

8.10. South Africa: Silage Baling for Cattle Feed

Application: In South Africa, where cattle farming is widespread, the 9YG-2.24D could be used for silage baling, a key process in preserving high-moisture forage. The machine’s flexible power requirements (55-100 kW) make it adaptable for different farm sizes, and its sensor-controlled bale density ensures consistent quality, which is critical for silage fermentation.

9. About us | Factory Capabilities & OEM Customization Services

At EVER-POWER, we understand that agriculture varies by region. Our manufacturing facility, located in a National Economic and Technological Development Zone, spans over 32,000 square meters and is equipped with CNC laser cutting machines, automatic welding lines, and electrostatic spraying lines. This advanced infrastructure allows us to offer superior Product Customization Services.

Whether you need a specific color scheme to match your tractor fleet (e.g., LS Blue or Kubota Orange),

modified hitch points for specific tractor linkages,

or reinforced pickup tines for particularly rocky terrain.

Our R&D center can accommodate your needs. We hold ISO9001 certification and strictly adhere to quality management systems to ensure that every customized unit meets global standards.

10. Customer Success Case:

"We’ve been using the 9YG-2.24D to bale corn stalks after harvest, and I have to say, this machine has been changed us a lot. It’s fast, reliable, and handles the toughest residues without clogging. Our productivity has definitely increased – we can now do more in less time. Definitely worth the investment!"---John from California"We’ve been using this baler for sugarcane, and it’s been perfect. The build quality is top-notch, and it doesn’t struggle with the tough fibrous material left after harvesting. The bales come out perfectly packed, and the machine runs smoothly at high speeds. It’s definitely boosted our post-harvest efficiency."---Carlos from São Paulo"Handling winter wheat residue has never been easier. The 9YG-2.24D’s powerful system manages dense straw without any issues, and it doesn’t break down even on our rough terrains. The high productivity rate makes it ideal for getting the job done before the spring season. Very impressed with this baler."----Sergey from Krasnodar"We use this baler to handle wheat and barley straw, and I’m really happy with its performance. The baling system is quick, and it compresses the straw perfectly. It’s made a huge difference in how we manage our residue, and the best part is that we don’t need to burn it anymore, which is great for the environment."---Michael from New South Wales"We’ve been using the 9YG-2.24D for silage baling on our cattle farm, and the results are outstanding. The baler’s sensor-controlled density system ensures that every bale is perfect for silage fermentation. It’s been a great investment for maintaining high-quality feed, especially in the dry months. I’m very satisfied with how it performs."---Liam from Western Cape10. Other products in the same series (2.24D)

11. Replaceable parts

11.1 Gearbox:

இணக்கமான மாதிரிகள்: EP-வட்ட பேலர் தொடர் (வட்ட பேலர், பரிமாற்ற விகிதம் 1:2, 35மிமீ 6-ஸ்ப்லைன் ஷாஃப்டுடன் இணக்கமானது).

பயன்பாடு: நியூ ஹாலந்து 630 அல்லது ஜான் டீரெ 535 க்கு ஏற்ற, PTO சக்தியை பேலிங் பொறிமுறைக்கு அனுப்புகிறது. அளவுருக்கள்: முறுக்குவிசை > 500 Nm, 20% எரிபொருள் சேமிப்பு.

இந்த கியர்பாக்ஸை ஏன் தேர்வு செய்ய வேண்டும்: தனிப்பயனாக்கக்கூடிய அளவு (250-300 மிமீ வரை குறைக்கக்கூடியது), பிசுபிசுப்பான மாசுபாடுகளுக்கு (ரப்பர் புகை) எதிர்ப்பு, IP65 பாதுகாப்பு. PTO ஷாஃப்ட்:

இணக்கமான மாதிரிகள்: EP-PTO தொடர் (1-3/8" Z6 ஸ்ப்லைன், சரிசெய்யக்கூடிய நீளம் 600-1200மிமீ).

பயன்பாடு: டிராக்டரை பேலர் மெயின் டிரைவோடு இணைக்கிறது, 9YG-1.0C வகைக்கு ஏற்றது. முறுக்குவிசை பரிமாற்ற திறன் >95%, SAE/EURO விளிம்புகளுடன் இணக்கமானது.

11.2 சங்கிலிகள் & ஸ்ப்ராக்கெட்டுகள்:

இணக்கமான மாதிரிகள்: ANSI #50/#60 சங்கிலிகள், EP-Sprocket உடன் (சுருதி 12.7-19.05mm, ரோலர் விட்டம் 10-12mm).

பயன்பாடு: கன்வேயர் பெல்ட்கள் அல்லது பிணைப்பு வழிமுறைகளில் பயன்படுத்தப்படுகிறது, சதுர/சுற்று பேலர் வைக்கோல் கடத்தலுக்கு ஏற்றது. அகலம் 25-40 மிமீ, அணிய-எதிர்ப்பு எஃகு பொருள்.

11.3 Couplings:

இணக்கமான மாதிரிகள்: EP-இணைப்பு 200 தொடர் (முறுக்குவிசை பொருத்தம் 500-1000 Nm).பயன்பாடு: கியர்பாக்ஸை பேலிங் ரோலருடன் இணைக்கிறது, அதிர்வைக் குறைக்கிறது.

11.4 ஹைட்ராலிக் சிலிண்டர்:

ஹைட்ராலிக் சிலிண்டர்: EP-HC தொடர் (துளை 50-100மிமீ, ஸ்ட்ரோக் 300-600மிமீ), பேல் தூக்குதலுக்கு ஏற்றது.தாங்கு உருளைகள் மற்றும் முத்திரைகள்: 6208-2RS தாங்கு உருளைகள், L10 ஆயுள் >10000 மணிநேரம், தூசி புகாத முத்திரை.இணக்கத்தன்மை அட்டவணை: Comer 250T உடன் முழுமையாக மாற்றக்கூடியது (முறுக்குவிசை பொருத்தம், விலையில் 35% மட்டுமே); flange வட அமெரிக்க 4-போல்ட் PTO வடிவத்துடன் பொருந்துகிறது.

அடிக்கடி கேட்கப்படும் கேள்விகள் (FAQ)

Here are answers to common questions regarding the 9YG-2.24D, optimized for voice search and local market concerns.

Q1. How does the 9YG-2.24D round baler handle wet rice straw conditions in Korea?

A1. The 9YG-2.24D excels in wet conditions due to its unique "Axial Flow" feeding mechanism and no-cam pickup, which significantly prevents clogging and blockage compared to traditional auger systems.

Q2. What is the minimum tractor horsepower required to operate this heavy-duty baler efficiently?

A2. To operate the 9YG-2.24D efficiently, you need a tractor with a minimum power output of 55kW (approx. 75HP), though 100kW is recommended for maximum speed on hilly terrain.

Q3. Can this baler be customized to fit different tractor hitch standards used in South Korea?

A3. Yes, as a direct manufacturer, EVER-POWER offers customization services to adapt the hitch and PTO connections to match specific Korean tractor brands like LS or TYM.

Q4. What is the advantage of the no-cam track pickup system for maintenance costs?

A4. The no-cam track design eliminates complex moving parts that often wear out, reducing maintenance downtime and parts replacement costs, which is vital for busy harvest seasons.

Q5. How many bales per hour can I expect when harvesting dry corn stalks?

A5. When harvesting dry corn stalks under optimal field conditions, the 9YG-2.24D can achieve a productivity rate of up to 100 bales per hour, significantly boosting daily output.

Q6. Where can I buy replacement net wrap and parts for this baler in Asia?

A6. We supply standard sized 2000x1.4m net wrap and spare parts through our distribution network. Please use the "Inquire Now" button to find your nearest authorized supplier.

Q7. Which specific environmental regulations does this machine help Korean farmers comply with?

A7. By efficiently baling straw for feed or biomass instead of burning it, this machine helps farmers comply with the Clean Air Conservation Act and qualifies them for fodder preservation subsidies.

Q8. How does the sensor-controlled density system improve the quality of silage bales?

A8. The sensors monitor pressure in real-time to ensure uniform density throughout the bale, which is crucial for anaerobic fermentation in silage, preventing spoilage and ensuring high-quality feed.

Q9. What is the transport width of the machine and is it road-legal in Korea?

A9. The working width is 3010mm. Please check local Korean road traffic laws for wide loads, but its traction design generally allows for safe short-distance transport between fields.

Q10. Does EVER-POWER provide technical support for initial setup and operator training?

A10. Absolutely, we provide comprehensive technical manuals and video support for setup. For large orders, we can arrange online or on-site operator training to ensure safe usage.

ஆசிரியர்: PXY