Tanım

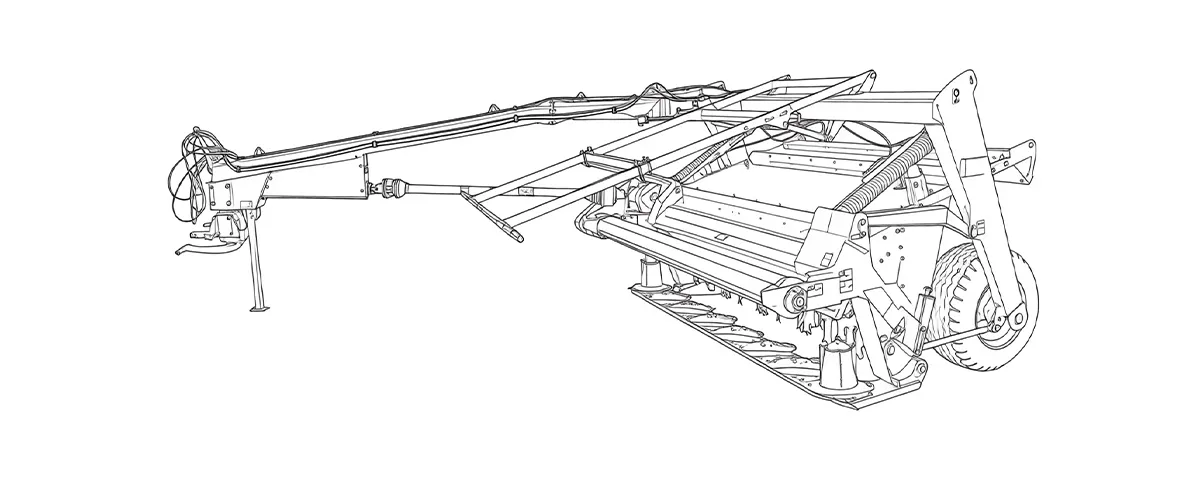

1. Technical Specifications: EP-9GD-2.5 Trailed Single-Blade Mower-Upgraded

| Specification Item | Birim | Data / Parameter |

|---|---|---|

| Model Adı | / | EP-9GD-2.5 Çekmeli Tek Bıçaklı Çim Biçme Makinesi - Geliştirilmiş |

| Hitch/Traction Type | / | Trailed (Drawbar Pull) |

| Cutter Structure | / | Reciprocating (Sickle Bar) |

| Cutting Width | M | 2.5 |

| Gerekli Güç | kW / hp | 15-35 kW / 20-50 hp |

| Çalışma Hızı | km/sa | 6 ~ 10 |

| Number of Blades | Pieces | 34 (Dynamic Blades) |

| Boyutlar (Uzunluk × Genişlik × Yükseklik) | mm | 2000 × 4300 × 950 |

| PTO Hızı | r/dakika | 540 |

| Avg. Stubble Height | mm | 50 – 70 |

| Verimlilik | hm²/sa | 2.0 – 3.0 |

| Yapısal Ağırlık | kilogram | 490 |

2. Redefining Efficiency in Forage Harvesting: The Upgraded 9GD-2.5 Trailed Mower

In the evolving landscape of modern agriculture, particularly within the diverse topographies of South Korea and East Asia, the demand for harvesting equipment that balances power efficiency with high output is critical. The 9GD-2.5 Trailed Single-Blade Lawn Mower (Upgraded Version) stands as a testament to engineering refinement, specifically designed to meet the rigorous demands of natural and planted pasture harvesting. Unlike heavy-duty rotary disc mowers that require substantial tractor horsepower, this reciprocating trailed mower operates with exceptional efficiency, requiring only 15-35 kW (20-50 HP). This makes it the ideal partner for the mid-sized tractors commonly found in provinces like Jeollanam-do and Gyeongsangbuk-do, where fuel economy and maneuverability are paramount. The “Upgraded Version” designation is not merely a label; it represents a significant enhancement in structural integrity, blade durability, and hydraulic responsiveness, ensuring that the machine delivers a consistent 2.5-meter cutting width without faltering, even during the peak harvest windows.

The operational philosophy behind the 9GD-2.5 is simplicity coupled with reliability. Designed for a single operator, the machine integrates seamlessly with the tractor’s hydraulic system to manage the lifting and lowering of the cutter bar. This feature is particularly beneficial when navigating the smaller, segmented fields often found in Korean agriculture, allowing for quick turns and easy transport between sites. Furthermore, while many market options focus on high-speed, high-impact cutting, the 9GD-2.5 utilizes a reciprocating action that ensures a clean cut with minimal crop shattering. This preservation of leaf integrity is crucial for maintaining the nutritional value of the forage, whether it be alfalfa, timothy, or native grasses.

By adhering to the GB/T10940-2008 standard and holding a valid Agricultural Machinery Test Appraisal Certificate, this unit offers farmers a verified, low-failure-rate solution that drastically reduces downtime during critical harvest periods.

3. Engineering Mechanics: Working Principle, Material Science, and Application Scenarios

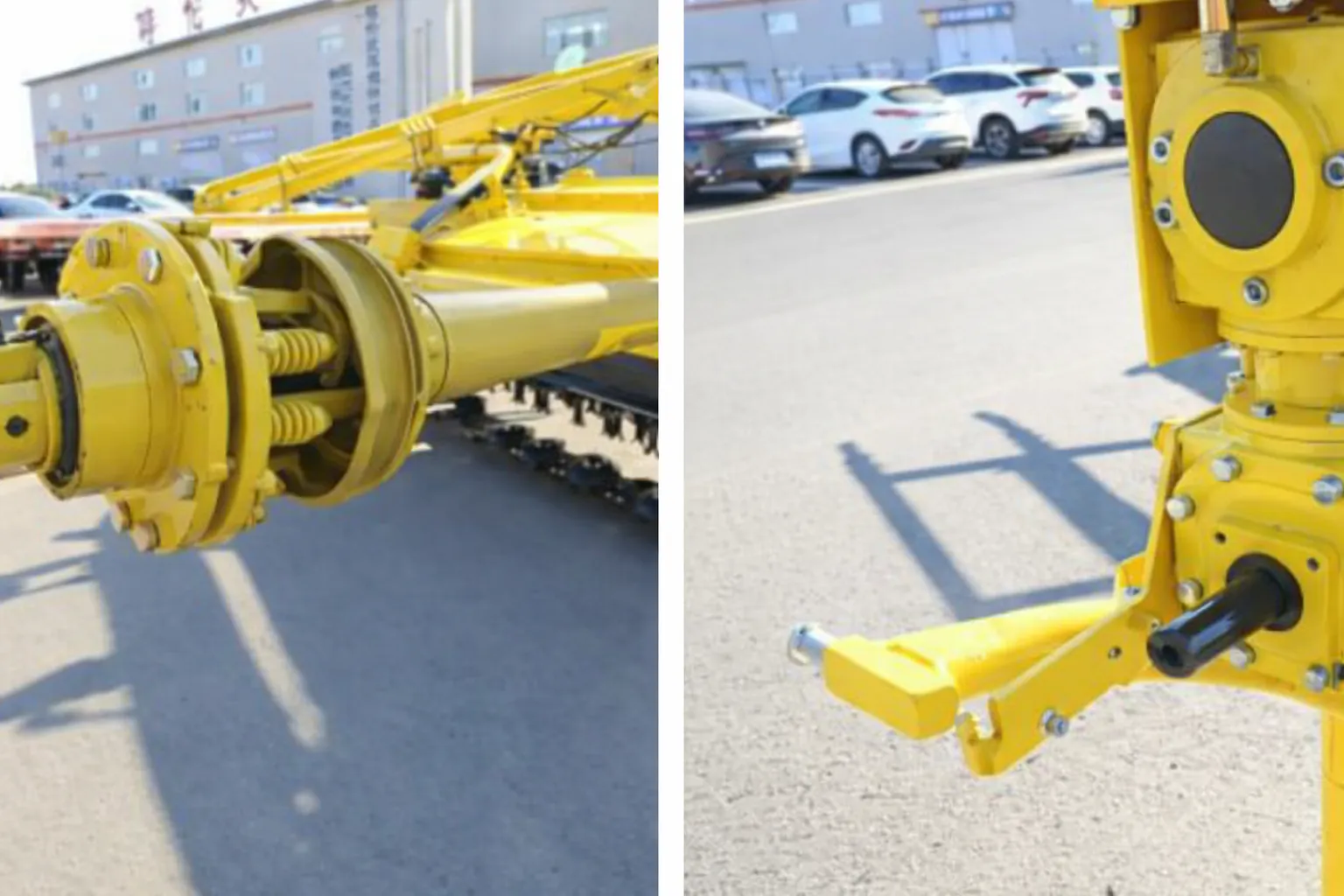

The core working principle of the 9GD-2.5 relies on a reciprocating cutting mechanism, often referred to as a sickle-bar system. Powered by the tractor’s PTO shaft at 540 r/min, the drive motion is converted into a linear oscillation that moves the 34 individual mower blades back and forth against stationary guards. This shearing action acts like a pair of scissors, slicing through plant stems cleanly rather than tearing them through impact. This mechanism is particularly advantageous for minimizing soil contamination in the swath, as it does not generate the high-velocity air suction associated with rotary mowers. The hydraulic lifting system allows the cutter bar to be raised efficiently for transport or to clear obstacles, enhancing the machine’s adaptability. The upgrade in this version includes a reinforced crank drive and improved bushing materials to withstand the high-frequency oscillation, reducing vibration transfer to the main frame and the towing tractor.

In terms of material composition, the 9GD-2.5 is constructed to endure. The main chassis utilizes Q345B high-strength structural steel, providing a rigid backbone that resists twisting forces on uneven terrain. The 34 dynamic mowing blades are forged from heat-treated 65Mn spring steel or specialized boron alloy, ensuring they retain a sharp edge longer and resist fracturing upon impact with small debris. Regarding application scenarios, this machine excels in flat to gently rolling fields of natural grass and cultivated forage crops. However, it is vital to note the limitations for optimal performance: it is not suitable for paddy fields, wetlands, dense forests, or areas with significant rock formations or “tussocks” (large clumps of roots/soil). In South Korea, where rice straw harvesting is common, this machine is better index-linked to the pre-rice harvest forage season or upland pasture management, offering a distinct advantage over complex zero turn mowers or smaller electric lawn mower units which are insufficient for agricultural scale production.

4. Global Safety Regulations and South Korean Compliance Standards

Navigating the regulatory landscape of agricultural machinery is essential for ensuring operator safety and legal compliance. The 9GD-2.5 is manufactured in strict accordance with the GB/T 10940-2008 standard for reciprocating mowers, ensuring it meets rigorous benchmarks for structural safety and performance consistency. For our South Korean clientele, we pay close attention to the requirements set forth by the Korea Agricultural Technology Promotion Agency (KOAT). This includes ensuring that all Power Take-Off (PTO) shafts are equipped with fully enclosed, non-rotating safety shields to prevent entanglement hazards—a critical compliance point in Korean agricultural safety laws. Furthermore, the hydraulic systems are designed to withstand pressures compliant with ISO standards, preventing leaks and ensuring fail-safe operation during lifting maneuvers.

Globally, and specifically in markets with strict environmental and safety directives like the EU and East Asia, machinery must minimize the risk of ejected debris. The 9GD-2.5’s reciprocating design naturally produces less flying debris compared to rotary mowers, but we still incorporate standard safety guards and clear warning decals in local languages (including Korean) to alert operators of danger zones. We also facilitate compliance with local road transport regulations by equipping the unit with standard mounting points for reflectors and slow-moving vehicle (SMV) signage, ensuring that when the unit is towed on public roads between fields in places like Gyeonggi-do, it remains visible and compliant with traffic laws. This dedication to regulatory alignment ensures a smooth import process and safe daily operation for the end-user.

5. 2026 Market Trends: The Shift Towards Efficient Forage Management

The agricultural machinery market in South Korea and the broader Asia-Pacific region is witnessing a distinct shift towards “Right-Sized Mechanization.” Historically, the trend favored larger, more powerful machinery. However, rising fuel costs and the fragmentation of arable land have led to a resurgence in demand for efficient, lower-horsepower implements like the 9GD-2.5 trailed mower. Farmers are increasingly prioritizing Total Cost of Ownership (TCO) over raw power. The reciprocating mower segment is experiencing growth because it offers a significantly lower fuel consumption rate per hectare compared to rotary drum or disc mowers. Furthermore, there is a growing emphasis on “Feed Quality” over “Harvest Speed.” Studies indicate that the clean shearing action of sickle bar mowers promotes faster regrowth of the crop stubble and reduces the ash content in the silage, aligning with the high-quality feed requirements of the Hanwoo beef and dairy sectors. This product fits perfectly into this trend, offering a sustainable, cost-effective solution for modern forage production.

6. Customer Success Story:

Client 1 Profile:

Customer Reviews:

Review by: Seojin Lee (South Korea)

“I’ve been using the 9GD-2.5 for a few months now on my farm in Jeollanam-do, and I’m impressed by how well it handles the diverse topography here. It’s lightweight and easy to operate with my 35HP tractor. The blade mechanism works flawlessly, and it cuts through my grass pastures with minimal mess. I especially love that the shearing action preserves the quality of the forage. It’s definitely a great investment for smaller farms looking for efficiency without breaking the bank.”

Client 2 Profile:

Customer Reviews:

Review by: Akira Nakamura (Japan)

“Running a small farm in Hokkaido, I needed a mower that was both cost-effective and reliable. The 9GD-2.5 ticked all the boxes. It’s powerful enough for my 50HP tractor, and it does a great job of keeping the grass cleanly cut without tearing it up. I also appreciate the improved hydraulic system for easy lifting and lowering. It’s definitely made my hay harvest much more efficient. Highly recommend it for farms that need something practical and durable.”

Client 3 Profile:

Customer Reviews:

Review by: John Miller (United States)

“I’ve been using the 9GD-2.5 on my farm in Oregon, and it’s a solid piece of equipment. The sickle bar system really works well for my timothy and alfalfa fields, providing a clean cut without soil contamination. It’s easy to maintain and doesn’t eat up too much fuel. The machine’s weight and size are perfect for my 45HP tractor, and it handles the job effortlessly. It’s a great machine for farmers who value fuel economy and efficiency!”

Client 4 Profile:

Customer Reviews:

Review by: Klaus Fischer (Germany)

“Here in Bavaria, we have a variety of terrain, and the 9GD-2.5 has proven to be an excellent match for the conditions. The cutting width is just right for my medium-sized fields, and the reciprocating action provides a clean cut every time. It’s also incredibly easy to maneuver, which makes moving between fields a breeze. The upgraded version with the reinforced chassis is definitely worth the extra investment. Great performance all around.”

Client 5 Profile:

Customer Reviews:

Review by: Marco De Luca (Italy)

“I’ve been using the 9GD-2.5 on my dairy farm in Tuscany, and it’s been an absolute game-changer. The mower works smoothly with my 40HP tractor, and I’ve noticed a significant improvement in how my pastures are managed. The clean cuts help preserve the nutritional content of the forage, and the machine is very reliable even in tougher conditions. It’s a cost-effective and efficient solution for forage management, and I highly recommend it for small to medium-sized operations like mine.”

7. Replaceable parts

7.1 Gearbox:

Uyumlu modeller: EP-Yuvarlak balya makinesi serisi (yuvarlak balya makinesi, aktarım oranı 1:2, 35 mm 6 dişli şaft ile uyumlu).

Uygulama: PTO gücünü balyalama mekanizmasına iletir, New Holland 630 veya John Deere 535 için uygundur. Parametreler: Tork > 500 Nm, 20% yakıt tasarrufu.

Bu şanzımanı neden tercih etmelisiniz: Özelleştirilebilir boyut (250-300 mm'ye kadar küçültülebilir), viskoz kirleticilere (kauçuk buharı) karşı dayanıklı, IP65 koruma sınıfı.7.2 PTO SHAFT:

Uyumlu Modeller: EP-PTO serisi (1-3/8″ Z6 kamalı bağlantı, ayarlanabilir uzunluk 600-1200 mm).

Uygulama: Traktörü balya makinesinin ana tahrikine bağlar, 9YG-1.0C tipi için uygundur. Tork iletim verimliliği >95%, SAE/EURO flanşlarla uyumludur.

7.3 Zincirler Dişliler ve Çarklar:

Uyumlu Modeller: ANSI #50/#60 zincirlerEP-Sprocket dişlisiyle (adım aralığı 12,7-19,05 mm, makara çapı 10-12 mm).

Kullanım Alanı: Konveyör bantlarında veya bağlama mekanizmalarında kullanılır, kare/yuvarlak balya makinelerinde saman taşıma için uygundur. Genişlik 25-40 mm, aşınmaya dayanıklı çelik malzeme.

7.4 Couplings:

Uyumlu Modeller: EP-Coupling 200 serisi (tork eşleşmesi 500-1000 Nm).Kullanım Alanı: Şanzımanı balyalama silindirine bağlar, titreşimi azaltır.

7.5 Hidrolik Silindir:

Hidrolik Silindir: EP-HC serisi (çap 50-100 mm, strok 300-600 mm), balya kaldırma için uygundur.Rulmanlar ve Contalar: 6208-2RS rulmanlar, L10 ömrü >10000 saat, toz geçirmez conta.Uyumluluk Tablosu: Comer 250T ile tamamen uyumludur (tork eşleşmesi, fiyatının sadece 35%'si); flanş, Kuzey Amerika 4 Cıvatalı PTO Desenine uygundur.

Sıkça Sorulan Sorular (SSS)

Q1. How much does the 9GD-2.5 trailed mower cost for delivery to Incheon port, South Korea?

A1. The price depends on the order quantity and current steel material costs. We offer competitive CIF Incheon rates. Please click “Get a Quote” for a precise estimate tailored to your volume.

Q2. Is this mower compatible with my 35HP LS Mtron tractor used in Korean farming?

A2. Yes, absolutely. The 9GD-2.5 is designed to operate efficiently with power inputs between 15-35 kW (20-50 HP), making it a perfect match for your 35HP LS tractor.

Q3. How often do I need to perform lawn mower blade removal or replacement on this unit?

A3. Blade life depends on the crop and soil conditions. Typically, blades should be inspected daily. Replacement is straightforward; unlike complex lawn mower blade removal on garden tractors, our sickle sections are bolted for quick exchange.

Q4. Can this trailed mower handle wet rice paddy stubble after the harvest?

A4. While it can cut straw, we generally advise against using this specific model in deep mud or wet paddy fields due to traction issues. It is best suited for dry or semi-dry pasture land.

Q5. Where can I find a supplier for replacement mowing blades in Korea?

A5. We supply a spare parts kit with every machine. Additionally, we can ship consumable parts like mower blades and guards directly to you via express courier within 3-5 days.

Q6. How does the upgraded version differ from the standard 9GD-2.5 mower?

A6. The upgraded version features a reinforced chassis, higher quality alloy steel for the 34 blades, and an optimized hydraulic lift system that provides smoother operation and better ground clearance.

Q7. Does this machine operate like a zero turn mower for tight spaces?

A7. No, this is a tractor-towed implement. While it has good maneuverability for a trailed mower, it does not have the zero-turn radius capability of a residential garden zero turn mower.

Q8. What hydraulic connections are required on the tractor for the lift mechanism?

A8. The mower requires a single standard hydraulic remote outlet on your tractor to operate the lifting cylinder for the cutter bar.

Q9. Can I visit your factory to see the 9GD-2.5 production line before ordering?

A9. Yes, we welcome international clients. We are located in the Hulunbuir Economic Zone. Please contact our sales team to schedule a visit and see our manufacturing process firsthand.

Q10. What is the warranty period for the gearbox and main frame components?

A10. We offer a 12-month warranty on the main frame and gearbox against manufacturing defects. Consumables like the mowing blade and fingers are excluded from the standard warranty.

Editör: PXY