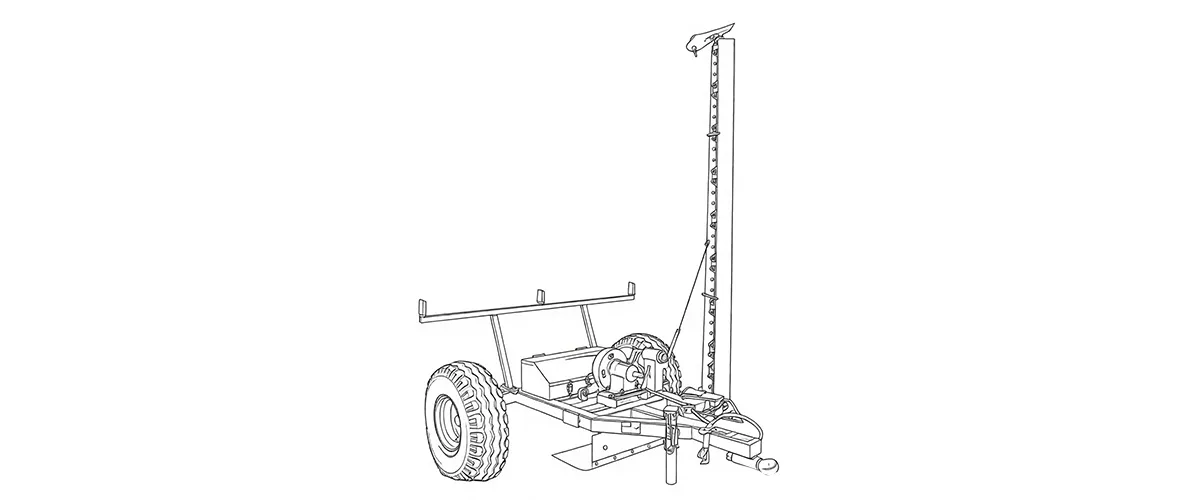

Опис

1. Technical Specifications: 9GD-2.5 Trailed Mower

| Item / Parameter | Unit | Specification Data |

|---|---|---|

| Model Name | / | Причіпна косарка з одним лезом EP-9GD-2.5 |

| Hitch/Mounting Method | / | Trailed (Traction Type) |

| Cutter Structure | / | Reciprocating (Sickle Bar) |

| Cutting Width | m | 2.5 |

| Matched Power | kW (HP) | 15 – 35 kW (20 – 50 HP) |

| Working Speed | km/h | 6 ~ 10 |

| Moving Blade Quantity | Pieces | 34 |

| Overall Dimensions (L×W×H) | mm | 2000 × 4300 × 950 |

| PTO Shaft Speed | r/min | 540 |

| Average Stubble Height | mm | 50 – 70 |

| Productivity | hm²/h | 2.0 – 3.0 |

| Operating Crew | Person | 1 |

| Structural Mass | kg | 490 |

View All Products Categories

2. Optimizing Forage Harvest with the 9GD-2.5 Trailed Single-Blade Mower

In the evolving landscape of modern agriculture, particularly within the diverse terrains of South Korea’s Jeollanam-do and Gangwon-do provinces, the demand for reliable, energy-efficient harvesting equipment is paramount. The 9GD-2.5 Trailed Single-Blade Mower stands as a premier solution for farmers utilizing mid-range tractors (20–50 HP). Unlike complex rotary systems that demand high horsepower and fuel consumption, this trailed mower utilizes a reciprocating cutting action that delivers a clean, scissor-like cut. This mechanism is crucial for preserving the nutritional value of natural and planted pastures, such as alfalfa and timothy grass, by minimizing leaf shatter during the harvest. With a substantial cutting width of 2.5 meters, this machine bridges the gap between small-scale operations and industrial efficiency, offering a productivity rate of 2.0 to 3.0 hectares per hour. Its design philosophy centers on simplicity and durability, ensuring that a single operator can manage the entire harvesting process from the tractor seat, utilizing the hydraulic system to lift and lower the cutter bar seamlessly.

The structural integrity of the 9GD-2.5 is engineered to withstand the rigors of continuous field use while maintaining a low structural mass of 490 kg. This lightweight footprint significantly reduces soil compaction—a critical factor for maintaining long-term soil health in intensive farming zones. While this machine excels in flat and slightly undulating pastures, it is specifically designed to avoid the operational hazards associated with wetland bogs, dense forests, or extremely rocky terrains often found in remote mountain areas. By adhering to the GB/T10940-2008 standard for reciprocating mowers, we ensure that every unit leaving our factory meets rigorous quality benchmarks. For the Korean market, where precision and reliability are non-negotiable, this mower offers an exceptional balance of performance and cost-effectiveness, making it a superior alternative to expensive, high-maintenance self-propelled units. It serves not just as a tool, but as a strategic asset for livestock farmers aiming to secure high-quality winter feed.

3. Engineering Excellence: Working Principles, Materials, and Application Scenarios

The core working principle of the 9GD-2.5 revolves around its reciprocating knife bar system, a time-tested technology refined for modern efficiency. Power is transmitted from the tractor’s PTO (Power Take-Off) at 540 r/min through a drive shaft to a crank-link mechanism. This converts the rotary motion into the linear reciprocating motion of the 34 moving mower blades. These blades slide back and forth against stationary guard fingers, shearing the grass stems cleanly rather than tearing them by impact. This method is scientifically proven to promote faster regrowth of the crop because the clean cut heals more rapidly than the ragged tear often left by dull rotary blades. The cutter bar assembly is constructed from high-grade alloy steel, heat-treated to resist wear and fatigue, ensuring that the mowing blade edge retains sharpness even after hectares of cutting abrasive silica-rich grasses. The hydraulic lifting mechanism allows the operator to raise the cutter bar to navigate headlands or transport the machine without disengaging the PTO, streamlining the workflow.

regarding application scenarios, the 9GD-2.5 is specifically tailored for “Natural and Planted Pastures.” In the context of South Korean agriculture, this makes it ideal for harvesting Italian Ryegrass (IRG) in paddy fields during the winter crop season, provided the ground is sufficiently dry. It is also perfectly suited for oat and forage rye cultivation areas. However, operational boundaries must be respected to ensure longevity. The machine is not designed for clearing wasteland with heavy brush, saplings, or significant rock deposits (“Tower Heads”). Operating in such environments can damage the lawn mower blades and the reciprocating drive arm. The machine’s traction-based design ensures stability, while the tires provide adequate flotation to prevent rutting. Whether you are maintaining a medium-sized dairy farm in Chungcheong or a beef cattle operation in Gyeongsang, the 9GD-2.5 adapts to your field conditions, delivering a consistent stubble height of 50-70mm, which is optimal for protecting the crop crown and ensuring vigorous regrowth for the next cutting cycle.

4. Global Standards and Local Compliance: Navigating Agricultural Safety Regulations

Navigating the regulatory landscape of agricultural machinery is essential for ensuring operator safety and legal compliance. The 9GD-2.5 trailed mower is manufactured in strict accordance with the Chinese National Standard GB/T10940-2008 for “Reciprocating Mowers,” which shares significant harmonization with international ISO standards regarding machinery safety and performance testing. For our clients importing into South Korea, we understand the importance of the Agricultural Mechanization Promotion Act. This equipment is designed to meet the safety inspection criteria set forth by the Korea Agricultural Technology Promotion Agency (KOAT). Key compliance features include shielded PTO shafts to prevent entanglement, hydraulic safety locks for transport, and clear safety decalage. We provide all necessary technical documentation to assist importers in obtaining the necessary certifications for local subsidies, which are often available for forage production equipment in Korea.

Furthermore, environmental considerations are increasingly becoming law in agricultural sectors worldwide. Unlike heavy diesel-guzzling self-propelled harvesters, the 9GD-2.5’s low power requirement (starting at just 15KW/20HP) aligns with global initiatives to reduce the carbon footprint of farming operations. By utilizing smaller, more fuel-efficient tractors, farmers can significantly lower their emissions per ton of grass harvested. In regions like the European Union or North America, where lawn mower blade removal and maintenance safety are strictly regulated, our design simplifies blade replacement, minimizing downtime and reducing the risk of injury during maintenance. Whether you are in Seoul, Tokyo, or Munich, operating machinery that adheres to established safety and environmental standards is not just a legal requirement; it is a moral imperative for the sustainable future of agriculture.

5. Customer Success Story: Transforming Harvests in Jeollabuk-do

Client 1 Profile:

Customer Reviews:

Review by: Haruto Sato (Japan)

“We’ve been using the 9GD-2.5 on our farm in Hokkaido for the past season, and it has been fantastic. The reciprocating cutting system is gentle on the grass, which is perfect for preserving the nutritional value in our timothy grass. The 2.5-meter cutting width allows us to cover a lot of ground quickly, and the hydraulic lift system is easy to operate. We’ve noticed a big difference in feed quality, and I’m glad we made the switch!”

Client 2 Profile:

Customer Reviews:

Review by: John Miller (United States)

“As a beef cattle farmer in Oregon, I was looking for something that could handle my hay fields efficiently, and the 9GD-2.5 was exactly what I needed. It’s easy to hook up to my 30HP tractor, and it handles the cutting process without any hassle. The quality of the cut is much better compared to my old mower, and I appreciate how it preserves the forage. The low fuel consumption is a bonus too, especially with rising fuel prices. I’m very satisfied with this mower!”

Client 3 Profile:

Customer Reviews:

Review by: Maria Schmidt (Germany)

“I’ve been using the 9GD-2.5 on our family farm in Bavaria, and I have to say, it’s a great investment. The machine is incredibly easy to use and works perfectly on our medium-sized fields. The reciprocating action ensures the grass is cut cleanly, and the 50-70mm stubble height is ideal for protecting the crown of the plants. It’s well-built, and the design keeps everything simple yet effective. It’s a much better option than the heavier rotary mowers!”

Client 4 Profile:

Customer Reviews:

Review by: Luca Bianchi (Italy)

“Running a dairy farm in Tuscany means dealing with uneven terrain, but the 9GD-2.5 handles it like a charm. The lightweight design and powerful cutting action make it easy to maneuver, and I can get the job done efficiently. The hydraulic lifting system makes transporting the mower between fields a breeze. The quality of the cut is excellent, and my pastures are thriving as a result. I highly recommend this mower to anyone looking for reliability and efficiency.”

6. 2025 Market Trends: The Resurgence of Reciprocating Mowers

While rotary disc mowers have dominated the high-speed harvesting market for years, 2024 and 2025 have seen a noticeable statistical shift back towards reciprocating technology like the 9GD-2.5, particularly in the Asian and Eastern European markets. The driving force behind this trend is the rising cost of fuel and the push for sustainable “Eco-Farming.” Reciprocating mowers require approximately 40-50% less horsepower per meter of cut compared to drum or disc mowers. In an era where diesel prices in South Korea and Japan are fluctuating, the ability to run a 2.5-meter mower with a simple 30HP tractor is a massive economic advantage. Furthermore, there is a growing agronomic focus on feed quality. Studies indicate that the gentle cutting action of sickle bars retains up to 15% more leaf mass in legumes like alfalfa compared to high-speed rotary impact, which shatters dry leaves. This directly translates to higher protein yield per hectare, making the 9GD-2.5 not just a budget choice, but a quality-conscious choice for feed production.

7. Replaceable parts

7.1 Gearbox:

Compatible models: EP-Round baler series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).

Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.

Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection.7.2 PTO SHAFT:

Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).

Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.

7.3 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).

Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.

7.4 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.

7.5 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.

Frequently Asked Questions (FAQ)

Q1. How much does the 9GD-2.5 mower cost including shipping to Incheon port, South Korea?

A1. The final price depends on the current steel market and shipping rates, but we offer very competitive FOB and CIF Incheon prices. Please click the “Get a Quote” button for a precise calculation tailored to your order volume.

Q2. Where can I buy replacement mower blades and guards if they break during harvest?

A2. We supply a comprehensive spare parts kit with every machine. Additionally, our blades use standard dimensions compatible with many common sickle bar mower parts found in local Korean agricultural supply stores.

Q3. My tractor is a 25HP Kubota; is it powerful enough to pull this 2.5m mower?

A3. Absolutely! One of the biggest advantages of the 9GD-2.5 is its low power requirement. It operates efficiently with tractors ranging from 15KW to 35KW (20-50 HP), making your 25HP Kubota a perfect match.

Q4. Can this machine handle harvesting tall reeds or corn stalks in wetland areas?

A4. While it handles tall pasture grass excellently, we do not recommend it for wetlands or heavy corn stalks. For those tougher conditions, please check our “Products Categories” for our heavy-duty flail mowers or round balers designed for stalks.

Q5. How do I adjust the stubble height for cutting different types of forage crops?

A5. The cutting height is adjustable between 50mm and 70mm. This is done by adjusting the skid shoes on the cutter bar, allowing you to protect the plant crown and ensure rapid regrowth.

Q6. Does the machine come with a warranty for the hydraulic cylinder and gearbox?

A6. Yes, we provide a 12-month manufacturer’s warranty covering all main components, including the gearbox and hydraulic system, against manufacturing defects.

Q7. How is the 9GD-2.5 different from a electric lawn mower or zero turn mower?

A7. The 9GD-2.5 is a heavy-duty agricultural implement for harvesting acres of feed for livestock, towed by a tractor. An electric lawn mower or zero turn lawn mower is for residential garden maintenance. They serve completely different purposes.

Q8. What happens if the mower hits a large rock while I am driving in the field?

A8. The machine is designed with a safety release mechanism. However, as it is a reciprocating mower, you should avoid rocky fields. If you operate in very rocky terrain, we recommend scanning the field first to prevent damage to the mower blades.

Q9. Do you offer OEM services to paint the mower to match my tractor fleet branding?

A9. Yes, we offer full OEM customization. We can paint the machine in any color code you specify and apply your company’s logos and decals before shipping.

Q10. How fast can I drive my tractor while operating this mower effectively?

A10. The recommended working speed is between 6 and 10 km/h. Exceeding this speed may result in an uneven cut or clogging of the cutter bar, while driving too slow reduces productivity.

Editor: PXY