EP-9YG-1.25A 圆捆打捆机

Engineered for high-density baling of Rice Straw, IRG, and Corn Stover.

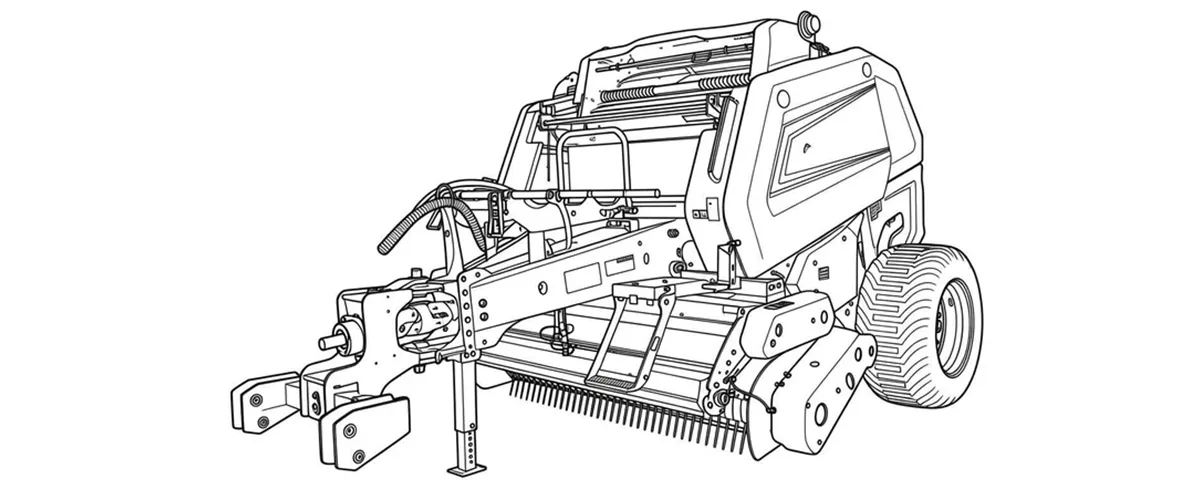

The 9YG-1.25A Round Baler is a heavy-duty agricultural machine designed by EVER-POWER, specifically optimized for the 1.25m x 1.3m bale format popular in Asian markets. Featuring a robust 18-roller compression chamber and a wide 2150mm spring-tooth pickup, it excels in collecting crops, including silage and straw. With a net structural weight of 4472 kg and requiring 75kW+ (100HP+) power, this machine ensures superior bale density and shape retention, directly addressing the logistics efficiency required by South Korea’s “Clean Air Conservation Act” for straw utilization.

1. Technical Specifications: 9YG-1.25A Data Sheet

1. Technical Data Sheet: 9YG-1.25A Specifications

| 项目编号 | 参数名称 | 单元 | 规格 |

|---|---|---|---|

| 1 | 型号名称 | / | 9YG-1.25A Round Baler |

| 2 | 挂钩类型 | / | 拖曳 |

| 3 | 拾音器宽度 | 毫米 | 2150 |

| 4 | 拾音器结构类型 | / | Roller + Pickup Teeth + Vane |

| 5 | 进料机构 | / | 进料转子+辊筒 |

| 6 | 压缩室宽度 | 毫米 | 1250 |

| 7 | 压缩室直径 | 毫米 | Φ1200 |

| 8 | 压缩辊数量 | 件 | 18 (rollers) |

| 9 | 辊径 | 毫米 | Φ222 |

| 10 | 装订方法 | / | 网状绑定 |

| 11 | 匹配功率 | 千瓦 | ≥75 |

| 12 | 结构重量 | 公斤 | 4472 |

| 13 | PTO转速 | 转/分钟 | 540-1000 |

| 14 | 尺寸(长×宽×高) | 毫米 | 4400 × 2850 × 2400 |

| 15 | 牧草密度控制 | / | 传感器控制 |

| 16 | 牧草尺寸(直径×宽度) | 毫米 | Φ1300 × 1250 |

| 17 | 牧草密度 | 千克/立方米 | 100 ~ 200 |

| 18 | 生产率 | 包/小时 | 40 ~ 100 |

| 19 | 轴距 | 毫米 | 2450 |

| 20 | 运行速度 | 公里/小时 | 5 ~ 35 |

| 21 | 网状包装规格 | / | 2000m x 1.25m per roll |

2. 关键工程事实

- Massive 4.4-Ton Chassis: Weighing 4472 kg, the 9YG-1.25A offers significantly higher stability and durability on uneven rice paddies compared to lighter competitors.

- 18-Roller Chamber Technology: Utilizes 18 reinforced steel rollers (Φ222mm) to create high-density bales (up to 200 kg/m³) without the belt slippage issues common in variable chambers.

- High-Speed Throughput: Engineered feeding system with auger and tine rollers achieves a productivity rate of 40-100 bales per hour, maximizing short harvest windows.

- Wide 2150mm Pickup: The 2.15-meter pickup width easily handles wide windrows from modern combine harvesters, reducing field passes and fuel consumption.

- Advanced Net Binding: Features an automated net binding system that wraps bales in seconds, ensuring weather protection and easier storage for silage fermentation.

3. Mechanics & Application: Why the 9YG-1.25A Dominates the Field

The operational success of the 9YG-1.25A Round Baler lies in its sophisticated "Force Feeding" mechanism. Unlike gravity-fed systems, this unit employs a dynamic combination of a 2150mm spring-tooth pickup, centering augers, and an aggressive tine roller.

This triad ensures that crop flow is continuous and turbulent-free, even when handling slick materials like semi-wilted Italian Ryegrass (IRG) or brittle corn stover. Once the material enters the fixed chamber, the 18 high-strength steel rollers engage immediately. These rollers, with a diameter of 222mm, are engineered with specific traction profiles to rotate the bale core effectively. As the bale grows, the rollers exert immense pressure, compacting the material from the outside in. This mechanical compression is crucial for silage production, as it expels oxygen rapidly, fostering the anaerobic conditions necessary for high-quality fermentation—a critical factor for Korea's Hanwoo beef industry.

Material science plays a pivotal role in the 9YG-1.25A’s longevity. The chassis is constructed from high-tensile alloy steel, treated with electrostatic powder coating to resist the corrosive acidic nature of silage juices and the humid climate often found in East Asia. The drive system is fortified with heavy-duty roller chains and sprockets that have undergone induction hardening. This robust construction allows the machine to withstand the high torque loads required to achieve bale densities of up to 200 kg/m³. For South Korean farmers operating in regions like Chungcheongbuk-do, where terrain can vary from flat paddies to rolling hills, the machine’s low center of gravity and wide wheelbase (2450mm) provide exceptional stability. The integration of a sensor-controlled density system allows operators to adjust bale weight on the fly, tailoring the output for either heavy silage or lighter straw bedding, making it a versatile asset for mixed-farming operations.

4. Regulatory Compliance

International Context:

4.1. South Korea: The 9YG-1.25A is a strategic tool for compliance with the "Wastes Control Act" and the "Clean Air Conservation Act", which strictly prohibit the open burning of agricultural by-products like rice straw and orchard prunings. The Korean government actively subsidizes equipment that facilitates the collection of straw for use as livestock feed (TMR) or compost. Utilizing the 9YG-1.25A allows farmers to efficiently clear fields, converting potential waste into a tradable commodity, thus avoiding heavy fines and contributing to the national "Fine Dust Reduction" initiatives. Furthermore, the high-density bales produced are compatible with the logistics requirements of the National Agricultural Cooperative Federation (Nonghyup) distribution centers.

4.2. European Union: Under the Common Agricultural Policy (CAP), soil health and carbon farming are prioritized. While retaining some straw is beneficial, removing excess for bio-energy must be done efficiently to minimize soil compaction. The 9YG-1.25A's flotation tires and high-efficiency single-pass capability align with these sustainable practices.

4.3. China: In line with the "Comprehensive Utilization of Crop Straw" policy, the 9YG-1.25A supports the complete ban on straw burning. Its ability to handle corn stover makes it ideal for the biomass power generation supply chain in Northeast China.

4.4. USA/Canada: For producers exporting forage to Asia, bale density is key to reducing shipping costs. The 9YG-1.25A creates export-grade, dense bales that maximize container weight limits, meeting the strict phytosanitary and density standards required for trans-Pacific trade.

| System / Part | 规格 | Compatible Brands/Standards |

|---|---|---|

| Tractor Linkage | Drawbar / PTO 6-Spline | LS Mtron, TYM, Daedong, John Deere 6 Series, Kubota M Series |

| 网状包装 | Width: 1.23m - 1.25m | Tama, Novatex, Pippo, and standard Korean market net rolls |

| 液压接口 | Standard Quick Coupler | ISO 7241-1 A (Universal Agricultural) |

6. Application Scenarios

6.1. Rice Paddy Harvesting & Straw Management

The 9YG-1.25A Round Baler is ideal for managing rice straw in regions like South Korea’s Chungcheong and Jeolla provinces. Its 2150mm wide pickup efficiently handles the dense, wet rice straw left by combine harvesters, creating high-density bales with minimal downtime. The baler’s sensor-controlled density system ensures that rice straw is properly compacted for use as livestock feed or bedding.

6.2. Silage Production for Livestock Feed

Farmers in South Korea and Japan can use the 9YG-1.25A to produce high-density silage bales for their livestock operations. The heavy-duty 18-roller chamber and advanced net binding system ensure the production of tightly packed bales that ferment efficiently, promoting better anaerobic conditions and preserving silage quality for Hanwoo beef production or dairy farms.

6.3. Multi-Crop Harvesting in Mixed Farms

For farms growing both rice and corn, the 9YG-1.25A offers versatility. It easily handles both wet, fibrous rice straw and dry, brittle corn stalks, making it suitable for mixed farming operations. The baler’s robust design ensures consistent performance, reducing downtime when switching between crops and optimizing overall farm productivity.

6.4. Biomass Collection for Bioenergy

The 9YG-1.25A is a critical tool for bioenergy producers, especially in regions like Northeast China, where corn stover is a key feedstock. The baler’s high-density output is perfect for transporting large quantities of biomass to power plants, maximizing transport efficiency and reducing overall logistics costs.

6.5. Forage Harvesting for TMR (Total Mixed Ration)

In South Korea, the 9YG-1.25A helps farmers produce high-quality forage for the livestock feed industry, particularly for TMR centers. The baler’s ability to handle both wet and dry forages, such as Italian Ryegrass (IRG) and alfalfa, makes it a go-to solution for large-scale operations aiming to supply consistent, dense bales for mixed feed production.

6.6. Corn Stover Recovery for Livestock Bedding

In regions where corn is grown for silage or grain, farmers can use the 9YG-1.25A to harvest and compact corn stover into bales for use as bedding material for livestock. The baler’s adjustable density system allows for lightweight straw bales ideal for bedding, helping reduce costs for livestock care while efficiently managing field residue.

6.7. Government Subsidy Compliance for Straw Management

The 9YG-1.25A enables farmers to comply with government policies such as South Korea’s "Wastes Control Act" and "Clean Air Conservation Act," which mandate the collection and proper disposal of agricultural waste like rice straw. The baler helps convert waste into valuable commodities, such as livestock feed or compost, thus meeting environmental standards while avoiding fines.

6.8. Post-Harvest Crop Residue Management in Hilly Terrain

In regions like Gangwon-do, where hilly terrains are common, the 9YG-1.25A’s low center of gravity and wide wheelbase (2450mm) provide superior stability. This makes it the perfect choice for farmers who need to clear crop residues, such as rice straw and corn stover, efficiently from uneven fields without compromising safety or performance.

6.9. Fodder Conservation for Emergency Feeding

During droughts or times of feed shortage, the 9YG-1.25A can be used to preserve large quantities of forage for emergency feeding. By baling both wet and dry forage crops like ryegrass and alfalfa, the machine ensures that farmers have adequate supplies of high-density silage, even during unpredictable weather conditions or low crop yields.

6.10. Export-Grade Baling for International Markets

For farmers exporting forage and silage to international markets such as Japan or the Middle East, the 9YG-1.25A ensures that bales meet the strict density and quality standards required for shipping. The baler’s high-density output and durable construction make it ideal for producing export-grade bales that maximize transport efficiency and ensure compliance with international standards.

7. Market Trend: The Shift to Heavy-Duty Baling in Asia

The agricultural machinery market in South Korea and East Asia is undergoing a distinct shift towards "High-Density & High-Speed" harvesting. Traditional small square balers are being replaced by high-capacity round balers like the 9YG-1.25A due to labor shortages in rural areas. The trend is moving away from twine binding to net wrapping, which reduces baling time by 50% per bale and improves outdoor storage capabilities. Furthermore, with the increasing price of imported feed, there is a "Home-Grown Forage" movement, driving demand for machines capable of handling heavy, wet silage crops (IRG, Rye) without clogging—a specific strength of the 9YG-1.25A’s roller-type chamber compared to belt balers which often struggle in wet conditions.

8. EVER-POWER Factory Customization

At EVER-POWER, we don't just assemble; we engineer. Our facility supports full OEM/ODM customization for the 9YG-1.25A model to suit specific regional needs.

- Color Coding: Custom paint jobs to match your dealership's fleet branding (e.g., Green, Red, Orange).

- Hitch Adaptation: Adjustable drawbars to fit varying tractor hitch heights found in different Korean provinces.

- PTO Splines: Options for 8-spline or 21-spline shafts for heavy-duty tractor compatibility.

- Reinforced Pickups: Optional hard-facing on pickup tines for abrasive volcanic soils.

Customer Success Story

10. 可更换部件

10.1 变速箱:

兼容型号:EP-Round 打捆机系列(圆打捆机,传动比 1:2,兼容 35mm 6 齿花键轴)。

应用:将动力输出轴 (PTO) 动力传递至打捆机构,适用于 New Holland 630 或 John Deere 535。参数:扭矩 > 500 Nm,20% 节油。

选择这款变速箱的理由:尺寸可定制(可缩小至 250-300 毫米),耐粘性污染物(橡胶烟雾),IP65 防护等级。动力输出轴:

兼容型号:EP-PTO 系列(1-3/8" Z6 花键,可调长度 600-1200 毫米)。

应用:连接拖拉机和打捆机主驱动装置,适用于9YG-1.0C型。扭矩传递效率>95%,兼容SAE/EURO法兰。

10.2 链条 链轮:

兼容型号:ANSI #50/#60 链条,带EP链轮(节距12.7-19.05mm,滚轮直径10-12mm)。

应用范围:用于输送带或捆扎机构,适用于方捆/圆捆打捆机秸秆输送。宽度25-40毫米,耐磨钢材质。

10.3 耦合:

兼容型号:EP-Coupling 200 系列(扭矩匹配 500-1000 Nm)。应用:连接齿轮箱和打包辊,抑制振动。

10.4 液压缸:

液压缸: EP-HC系列(缸径50-100mm,行程300-600mm),适用于捆包提升。轴承和密封件:6208-2RS 轴承,L10 寿命 >10000 小时,防尘密封。兼容性表格:与 Comer 250T 完全互换(扭矩匹配,价格仅为 35%);法兰与北美 4 螺栓 PTO 模式匹配。

常见问题解答 (FAQ)

Q1. How does the 9YG-1.25A handle wet Italian Ryegrass (IRG) compared to belt balers?

A1. The 9YG-1.25A excels in wet IRG conditions because it uses a fixed steel roller chamber. Unlike belt balers which rely on friction and can slip when the crop is wet and slimy, the steel rollers with traction profiles ensure positive rotation of the bale, preventing stoppages and ensuring a high-density silage bale every time.

Q2. Is the 2150mm pickup width suitable for the standard combine windrows in South Korea?

A2. Absolutely. The 2150mm pickup is specifically sized to handle the wide, heavy windrows left by modern large-scale combine harvesters used in Korean rice paddies. It allows you to collect the full windrow width without weaving, significantly speeding up the baling process.

Q3. What is the minimum tractor horsepower needed to operate this baler on hilly terrain?

A3. While the base requirement is 75 kW (approx. 100 HP), for operations in hilly regions like Gangwon-do, we recommend a tractor with 110-120 HP. The extra power ensures safe towing of the 4.4-ton machine and maintains consistent PTO RPM during uphill baling.

Q4. Can I get replacement parts like pickup tines and bearings quickly in South Korea?

A4. Yes, EVER-POWER prioritizes after-sales support. We supply a comprehensive spare parts kit with the machine. For ongoing needs, we can ship parts directly to major Korean ports or through our local partners, ensuring minimal downtime during the critical harvest season.

Q5. Does the machine come with a warranty for the main gearbox and rollers?

A5. Yes, we provide a standard 12-month warranty covering the main gearbox, compression rollers, and hydraulic components against manufacturing defects. We stand by the durability of our heavy-duty construction.

Q6. How does the net binding system improve efficiency compared to twine?

A6. Net binding is roughly 3 times faster than twine binding. It wraps the bale edge-to-edge in just a few rotations (typically 2-3 turns), reducing the stop time for each bale. This adds up to significantly more bales per hour and better weatherproofing for outdoor storage.

Q7. What is the price range for the 9YG-1.25A and do you offer shipping to Incheon?

A7. Pricing depends on configuration and order volume. We offer competitive factory-direct pricing significantly lower than European brands. We handle full logistics, including shipping containers (CIF/FOB) to Incheon, Busan, or Pyeongtaek ports. Please click "Get a Quote" for a specific offer.

Q8. Can this baler process dry corn stalks for biomass power plants?

A8. Yes, the 9YG-1.25A is robust enough to bale dry corn stover. The "Force Feeding" auger system effectively crushes brittle stalks, and the heavy rollers compact them tightly, making it ideal for high-density transport to biomass energy facilities.

Q9. Is technical training available for my operators who are new to round balers?

A9. We provide detailed operation manuals and video tutorials in English. For fleet purchases, we can arrange for virtual technical training or on-site guidance to ensuring your team understands maintenance and operation best practices.

Q10. How do I adjust the bale density for different crops?

A10. The 9YG-1.25A features a sensor-controlled density system. You can monitor and adjust the hydraulic pressure settings to change the bale density from the tractor cab or the baler control valve, allowing you to switch between loose straw and tight silage bales easily.

Ready to Upgrade Your Harvest Fleet?

Contact EVER-POWER today for the best factory price on the 9YG-1.25A Round Baler.

编辑:PXY