Description

1. Technical Specifications: 9GQY-3.2 Mower Conditioner

| Article de spécification | Unité | Données / Paramètres |

|---|---|---|

| Nom du modèle | / | 9GQY-3.2 Mower Conditioner |

| Type d'attelage/de traction | / | Side Traction / Pull-type |

| Largeur de coupe | m | 3.2 |

| Structure de coupe | / | Rotary Disc Type |

| Disc Quantity | Pièces | 8 |

| Blade Quantity | Pièces | 16 (2 per disc) |

| Conditioner Type | / | Impact Tooth / Flail |

| Swath Width Range | m | 0.8 – 2.2 (Adjustable) |

| Puissance requise | kW / ch | ≥ 80.88 kW / 110 hp |

| Vitesse de travail | km/h | 6 ~ 15 |

| Vitesse de prise de force | r/min | 540 – 1000 |

| Dimensions (L×l×H) | mm | 6750 × 3500 × 2000 |

| Poids structurel | kg | 2185 |

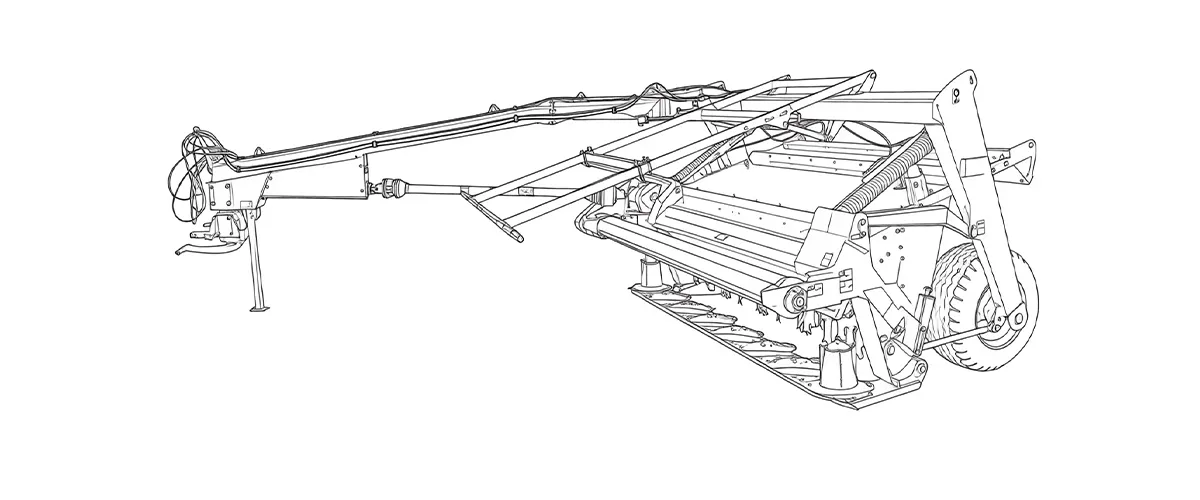

2. Revolutionizing Forage Harvest: The 9GQY-3.2 Pull-Type Mower Conditioner

In the competitive landscape of modern agriculture, particularly within the specialized forage markets of South Korea and East Asia, the efficiency of harvesting machinery dictates the quality of the final feed. The 9GQY-3.2 Mower Conditioner represents the pinnacle of pull-type harvesting technology, specifically engineered to handle high-density gramineous forage, alfalfa, and even tough reeds found in wetland areas. Unlike standard disc mowers that simply cut, this machine integrates a sophisticated conditioning system that mechanically abrades the waxy cuticle of the plant stems. This process significantly accelerates moisture evaporation, ensuring that the leaves and stems dry at a uniform rate, thereby preserving the nutritional value (crude protein and sugars) essential for high-yield livestock farming. For farmers in regions like Gangwon-do or Jeollanam-do, where weather windows for drying hay can be short and unpredictable, this capability is not just a luxury—it is an operational necessity. By combining a wide 3.2-meter cutting width with a heavy-duty rotary cutter capability, the 9GQY-3.2 ensures that large acreages are covered rapidly, reducing fuel consumption per hectare and minimizing soil compaction through its optimized weight distribution.

Furthermore, the structural integrity of the 9GQY-3.2 is built upon a foundation of engineering excellence, distinguishing it from generic mower conditioner for sale listings found on the global market. It features a proprietary “Super Floating Protection Device.” This intelligent mechanical system allows the cutter bar to automatically lift and float over obstacles such as hidden rocks, tree roots, or uneven field ridges—common challenges in diverse terrains. Once the obstacle is cleared, the unit automatically resets to the precise working height without operator intervention. This dual-suspension design, where the cutting system and the conditioning unit operate independently of the main frame, ensures superior ground profiling. This means that whether you are harvesting on the flat plains of Gimje or the rolling hills near Pyeongchang, the cut remains clean and consistent, preventing dirt contamination in the silage. As a trusted hay conditioner solution, Ever-Power delivers a machine that balances rugged durability with the precision required for premium dairy and beef cattle feed production.

3. Engineering Precision: Working Principle, Materials, and Application Scenarios

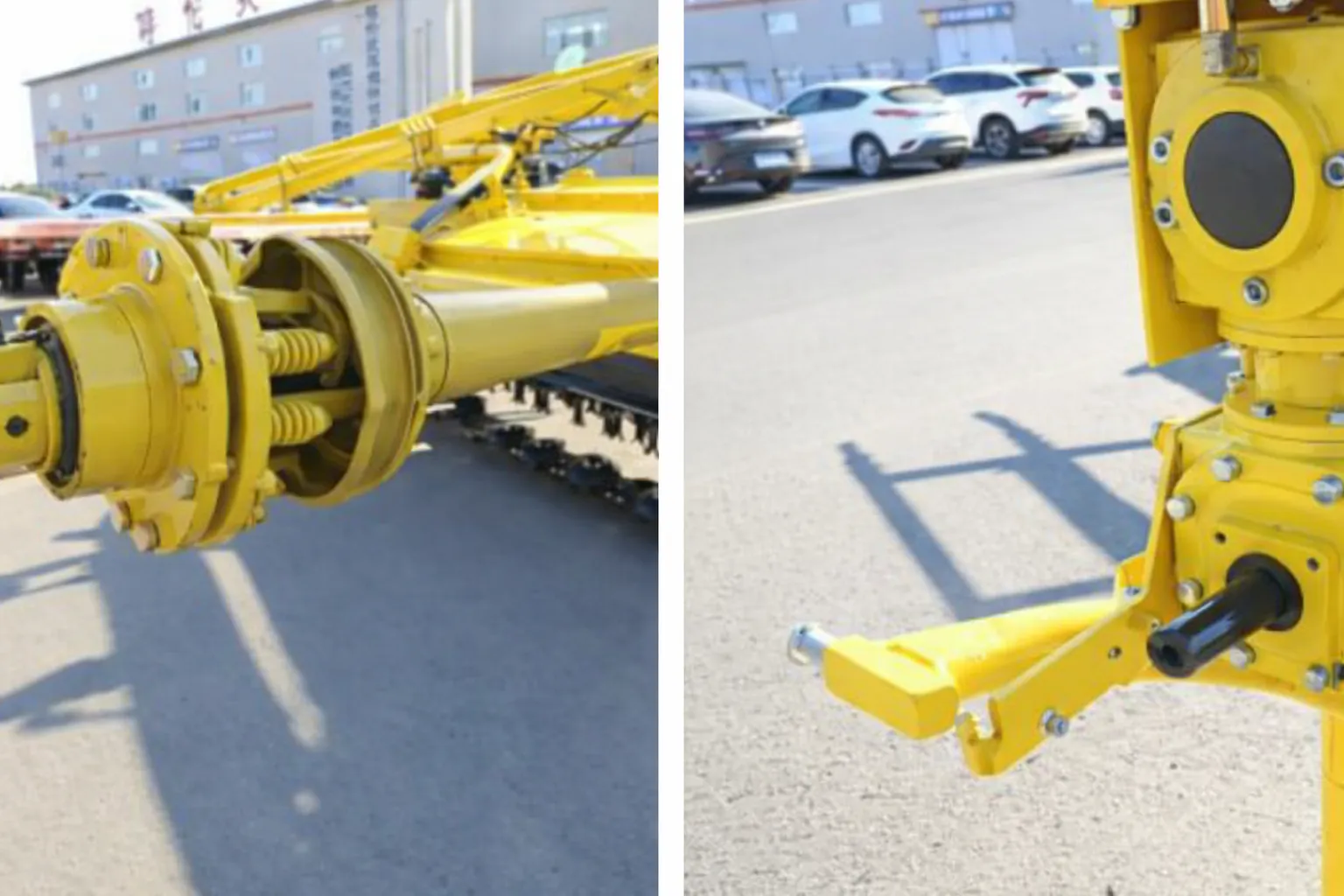

The operational heart of the 9GQY-3.2 lies in its synchronized rotary cutting and conditioning mechanism. Power is transmitted from the tractor’s PTO (540-1000 r/min) through a heavy-duty gearbox to the cutter bar, which houses 8 integrated discs equipped with 16 hardened alloy steel blades. As the crop is severed, it is immediately fed into the conditioning rollers. We utilize a “Flail/Hammer Tine” conditioning system, which is far more effective for grass-type crops than rubber rollers. These tines strike the stems, creating micro-fractures that facilitate rapid water loss. Regarding material composition, the cutter bar is constructed from reinforced boron steel to withstand high-impact loads, while the main chassis utilizes Q345B high-strength structural steel, ensuring longevity even under high-vibration conditions. The protective covers are made from weather-resistant, UV-stabilized polymers and heavy-gauge sheet metal, fully compliant with international safety standards to protect the operator from flying debris.

The application scenarios for the 9GQY-3.2 are vast and varied. Primarily, it excels in the harvesting of ryegrass, oats, and alfalfa, where retaining leaf quality is paramount. However, its robust design also makes it suitable for clearing reeds in wetland management projects or harvesting bio-energy crops. In the context of the South Korean market, where rice straw is often collected for feed, this machine can be adapted to manage heavy residues effectively. The unique “Side Traction” towing method allows the tractor to drive on the cut stubble or the unharvested crop without trampling the swath, optimizing the field traffic pattern. This makes it a superior alternative to a standard new holland disc mower for farmers requiring multifunctionality. Whether dealing with the humid summers of Asia or the dry harvesting seasons of North America, the 9GQY-3.2 adapts to deliver consistent, fluffy, and quick-drying windrows.

4. Global Safety Standards and Regional Compliance (Korea Focus)

Navigating the complex landscape of agricultural machinery regulations is part of our commitment to quality and safety. The 9GQY-3.2 Mower Conditioner is designed and manufactured in strict accordance with ISO 4254-1 (Agricultural machinery – Safety – Part 1: General requirements) and ISO 4254-12 (Rotary disc mowers and flail mowers). These standards mandate specific guarding for moving parts, noise emission limits, and the integrity of the protective skirt to prevent ejected objects. For our partners and clients in South Korea, we ensure alignment with the rigorous standards set by the Agence coréenne de promotion des technologies agricoles (KOAT) and compliance with the FACT (Foundation of Agri. Tech. Commercialization & Transfer) testing protocols. This includes ensuring that PTO shafts are fully shielded and that the hydraulic locking mechanisms for transport are fail-safe, meeting the local road transport safety laws for agricultural equipment. By adhering to these stringent legal frameworks, we guarantee that importing and operating our machinery is seamless and devoid of regulatory hurdles.

5. Compatibility & Market Comparison

| Feature / Component | Ever-Power 9GQY-3.2 | Typical New Holland Discbine Style | John Deere Mower Conditioner Style |

|---|---|---|---|

| Hitch Compatibility | Universal Drawbar / 2-Point (Cat II/III) | Drawbar / Swivel Hitch | Drawbar / Swivel Hitch |

| Conditioning Mechanism | High-Impact Steel Flails (Best for grassy forage) | Rubber Rolls or Flails | Impeller or Urethane Rolls |

| Obstacle Protection | Auto-Lift Super Floating System | Shock Hubs | Shear Hubs |

| Coût d'entretien | Low (Standardized parts) | High (Proprietary parts) | High (Proprietary parts) |

| Tractor Power Req. | 110 HP + | Typically 100 HP + | Typically 100 HP + |

6. 2025-2026 Forage Machinery Market Trends: Why Efficiency Matters

The global forage harvesting market is witnessing a distinct shift towards “Intelligent Drying” and “Wide-Area Efficiency.” In markets like South Korea, Japan, and parts of Europe, the trend is moving away from simple sickle-bar mowers towards integrated mower conditioners. Why? The changing climate patterns have led to shorter, more unpredictable dry spells. Farmers can no longer afford to leave hay drying in the field for 3-4 days. Equipment like the 9GQY-3.2, which can reduce drying time by up to 30-40% through mechanical conditioning, is becoming the industry standard. Furthermore, there is a rising demand for equipment that offers high durability with lower Total Cost of Ownership (TCO). While premium brands like John Deere discbine ou New Holland haybine remain popular, data shows a significant surge in interest for high-quality, cost-effective alternatives that deliver comparable performance metrics. The 9GQY-3.2 is perfectly positioned to meet this trend, offering top-tier conditioning performance at a price point that maximizes ROI for medium-to-large scale dairy operations.

7. Customer Success Story: Transforming Harvest in Gangwon-do

Profil du client 1 :

Avis des clients :

Review by: Joon Hyun (South Korea)

“I run a medium-sized dairy farm in Gangwon-do, and I’ve been using the 9GQY-3.2 for the past season. I was blown away by how much faster the hay dries compared to my old mower. The conditioning system really makes a difference, and with unpredictable weather, that 30-40% faster drying time is a game-changer. Plus, it handles the rocky terrain here like a pro. The auto-lift system is super handy. Highly recommend this machine for anyone in Korea who deals with wetland or grassy forages!”

Profil du client 2 :

Avis des clients :

Review by: Hiroshi Tanaka (Japan)

“I’ve used several mower conditioners over the years, but the 9GQY-3.2 stands out for its sheer power and efficiency. The 3.2-meter cutting width is perfect for my large-scale fields in Hokkaido, and the flail system really speeds up the drying process. I also appreciate the machine’s toughness and the fact that it doesn’t require a lot of maintenance. It’s become an essential part of my operation.”

Profil du client 3 :

Avis des clients :

Review by: Michael Carter (United States)

“As a beef cattle farmer in Oregon, I rely on my mower conditioner to get the job done quickly. The 9GQY-3.2 has been fantastic. It cuts and conditions ryegrass so efficiently. The fact that I can keep the cuttings fluffy and dry quickly has made a big impact on the quality of my feed. The setup was straightforward, and the customer service was top-notch. Worth every penny!”

Profil du client 4 :

Avis des clients :

Review by: Anita Schmidt (Germany)

“I was initially hesitant about switching to the 9GQY-3.2, but after trying it for a few weeks, I am convinced. In the humid conditions of southern Germany, the speed at which this machine dries the grass has cut my labor and drying times down significantly. It’s easy to adjust, and it’s robust enough for my diverse terrain. If you want to get high-quality hay and have minimal downtime, this machine is worth it.”

Profil du client 5 :

Avis des clients :

Review by: Marco Rossi (Italy)

“Running a dairy farm in Tuscany means dealing with challenging terrain and varying weather, but the 9GQY-3.2 makes it all easier. The floating protection system is a lifesaver, especially when I’m cutting through uneven fields. Plus, the high-impact flail conditioner does wonders for grass and even some tougher crops. It’s efficient, easy to maintain, and helps me save on fuel. A great investment for anyone looking to up their hay production game in Italy.”

8. Pièces remplaçables

8.1 Boîte de vitesses :

Modèles compatibles : série de presses à balles rondes EP (presse à balles rondes, rapport de transmission 1:2, compatible avec arbre cannelé 6 cannelures de 35 mm).

Application : Transmet la puissance de la prise de force au mécanisme de pressage, convient aux New Holland 630 ou John Deere 535. Paramètres : Couple > 500 Nm, économie de carburant 20%.

Pourquoi choisir cette boîte de vitesses : Taille personnalisable (réductible à 250-300 mm), résistante aux contaminants visqueux (fumées de caoutchouc), protection IP65.8.2 ARBRE DE PRISE DE FORCE :

Modèles compatibles : Série EP-PTO (Cannelure Z6 de 1-3/8″, longueur réglable 600-1200 mm).

Application : Raccordement du tracteur à la transmission principale de la presse à balles, compatible avec le modèle 9YG-1.0C. Rendement de transmission du couple > 95%, compatible avec les brides SAE/EURO.

8.3 Chaînes et pignons :

Modèles compatibles : ANSI #50/#60 chaînes, avec pignon EP (pas 12,7-19,05 mm, diamètre du rouleau 10-12 mm).

Application : Utilisé dans les convoyeurs à bande ou les mécanismes de liage, convient au transport de paille en balles carrées/rondes. Largeur : 25 à 40 mm, matériau : acier résistant à l’usure.

8.4 Accouplements :

Modèles compatibles : Accouplement EP série 200 (couple adapté 500-1000 Nm).Application : Relie la boîte de vitesses au rouleau de la presse à balles, amortit les vibrations.

8.5 Cylindre hydraulique:

Vérin hydraulique : Série EP-HC (alésage 50-100 mm, course 300-600 mm), adaptée au levage de balles.Roulements et joints : roulements 6208-2RS, durée de vie L10 > 10 000 heures, joint étanche à la poussière.Tableau de compatibilité : Entièrement interchangeable avec Comer 250T (couple correspondant, seulement 35% de moins au prix) ; la bride correspond au modèle de prise de force à 4 boulons nord-américain.

Foire aux questions (FAQ)

Q1. How much does the 9GQY-3.2 mower conditioner cost, including shipping to Busan, South Korea?

A1. The price varies based on order volume and current steel prices. However, we offer very competitive CIF Busan rates. Please click the “Get a Quote” button for a precise calculation tailored to your location.

Q2. Is this machine compatible with my 100HP John Deere tractor PTO shaft?

A2. Yes, the 9GQY-3.2 requires a minimum of 80.88 kW (approx. 110 HP) for optimal performance, though it can operate on slightly lower power in lighter crops. It comes with a standard 6-spline or 8-spline PTO shaft compatible with major brands.

Q3. Where can I find replacement parts for this mower conditioner in the local market?

A3. We provide a comprehensive spare parts kit with every machine. Additionally, we use standardized bearings and hydraulic components that are interchangeable with common parts found in local agricultural supply stores in Korea.

Q4. Which type of crop is the flail conditioner best suited for harvesting?

A4. The flail/hammer tine conditioner is specifically designed for gramineous forage (grasses) and reeds. It effectively scrapes the waxy stem surface to speed up drying, which is superior to rubber rollers for these crop types.

Q5. How does the super floating protection device work on rocky terrain?

A5. When the cutter bar hits a rock or stump, the hydraulic suspension system instantly reduces the downward pressure, allowing the header to lift up and over the obstacle, then automatically return to the cutting height, preventing gear damage.

Q6. What is the delivery lead time for a 9GQY-3.2 mower conditioner order?

A6. For standard configurations, our production time is typically 15-20 days. Shipping to South Korean ports usually takes an additional 3-7 days depending on the vessel schedule.

Q7. Can you customize the color to match my existing new holland haybine fleet?

A7. Absolutely. We offer full OEM customization services, including custom color painting, logo placement, and specific decal requirements to match your existing brand identity or fleet aesthetics.

Q8. How does the 9GQY-3.2 compare to a discbine for sale in terms of drying speed?

A8. The 9GQY-3.2 utilizes a similar rotary disc and conditioning technology as a standard discbine. Our testing shows it achieves comparable drying rates, reducing field curing time by 30-40% compared to non-conditioning mowers.

Q9. What is the warranty period for the gearbox and cutter bar?

A9. We offer a 12-month standard warranty on the main gearbox and cutter bar components against manufacturing defects. We also provide lifetime online technical support for all our customers.

Q10. Do you supply the necessary hydraulic hoses and connectors for Korean tractors?

A10. Yes, the machine comes fully equipped with standard hydraulic hoses and quick-couplers. If your tractor requires specific thread types (e.g., metric vs. BSP), please let us know when ordering, and we will adapt them accordingly.

Keywords utilized in this content: mower conditioner for sale, disc mower, hay conditioner, hay conditioner for sale, new holland discbine (contextual comparison), new holland disc mower (contextual), john deere moco (contextual), john deere mower conditioner (contextual), john deere discbine (contextual), new holland haybine (contextual), new holland mower conditioner (contextual), discbine (contextual), 9GQY-3.2, pull-type mower conditioner, agricultural machinery South Korea.